Semi-flexible electromagnetic ultrasonic probe for defect detection of pipeline components

A defect detection and electromagnetic ultrasonic technology, which is applied in the direction of material analysis, measurement device, and instrument using sonic/ultrasonic/infrasonic waves, can solve the problems of unsatisfactory effect of non-planar components, reduce the equivalent lift-off distance, and improve detection. Efficiency, the effect of increasing the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

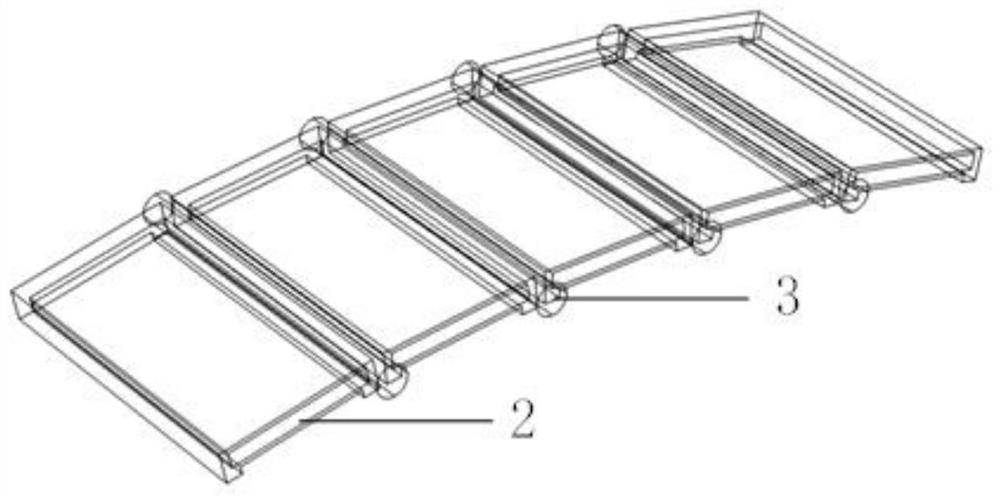

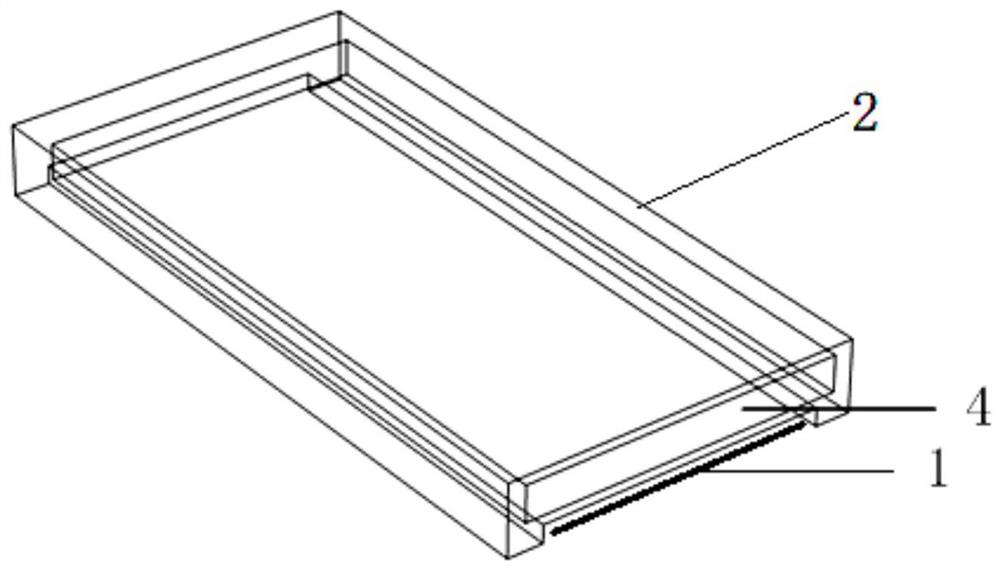

[0033] Such as figure 1 , which is a semi-flexible electromagnetic ultrasonic probe for defect detection of pipeline components according to the present invention, which includes a plurality of probe monomers sequentially connected by a rotating shaft mechanism 3, and the probe monomer includes an excitation coil circuit board 1, a probe housing 2 and a permanent magnet 4, The interior of the probe housing 2 is hollow, the excitation coil circuit board 1 is fixed on the detection surface where the probe housing 2 and the workpiece to be tested are attached, and the permanent magnet 4 is arranged inside the probe housing 2; the excitation coil circuit board of the adjacent probe monomer 1 Connect to the ultrasonic testing system after connecting in sequence.

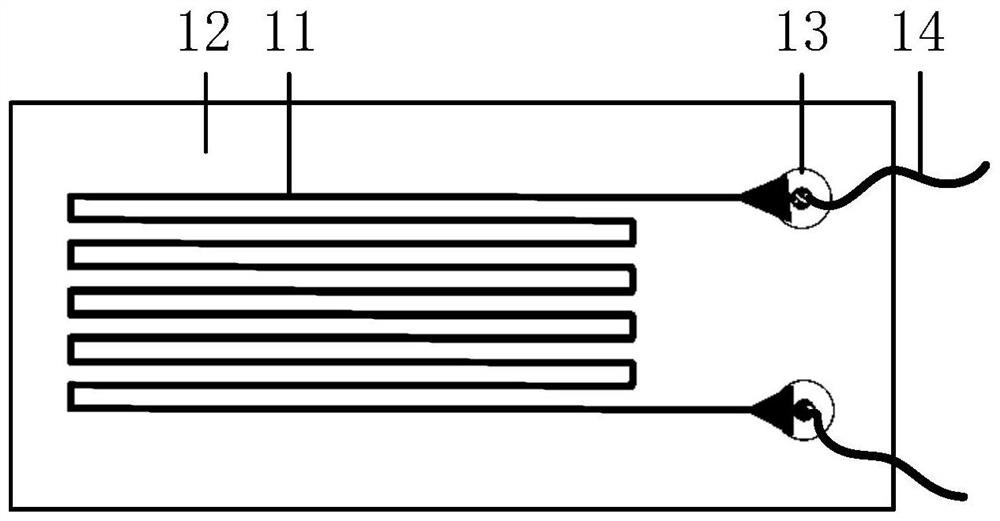

[0034] Such as image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanent flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com