Method for detecting reliability of board-level BGA (Ball Grid Array) package under fire smoke

A reliability and smoke technology, applied in the field of reliability detection of board-level BGA packaging under fire smoke, can solve problems such as low efficiency, body damage, and long detection process, so as to improve detection efficiency, improve accuracy, reduce poor repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. But following embodiment only limits to explain the present invention, and protection scope of the present invention should comprise the whole content of claim, and by the narration of following embodiment, those skilled in the art can fully realize the whole content of claim of the present invention.

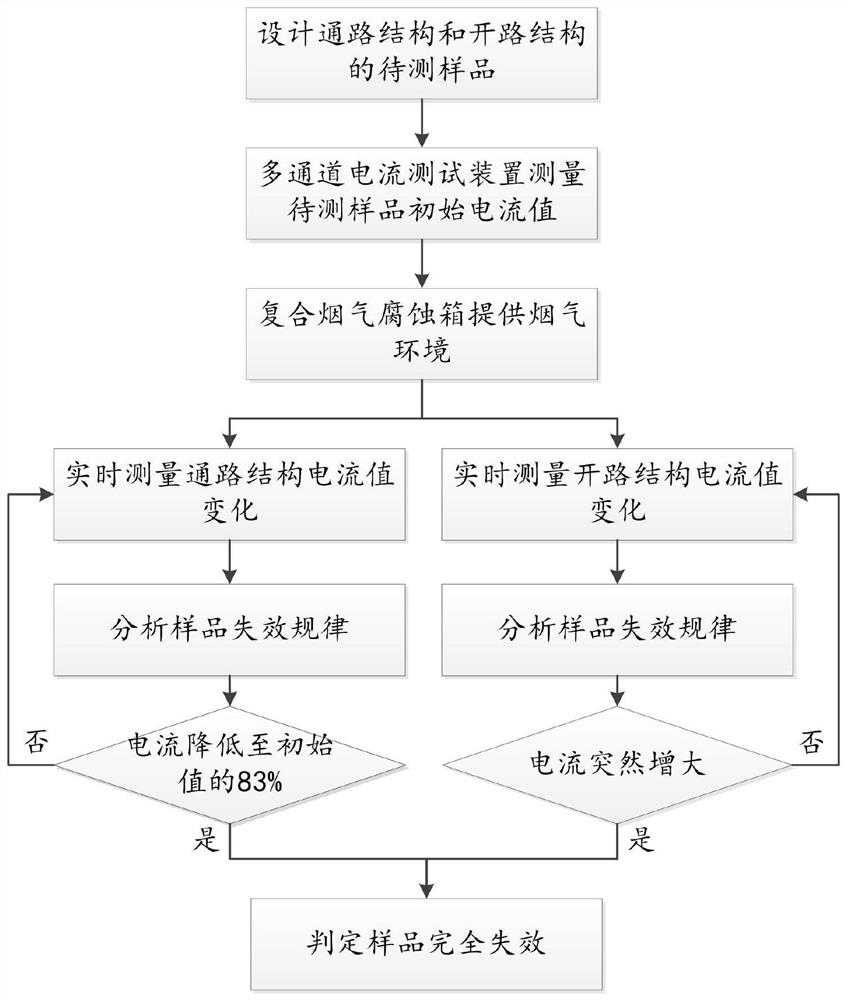

[0021] Such as figure 1 , 2 As shown, a method for detecting the reliability of board-level BGA packaging under fire smoke, including:

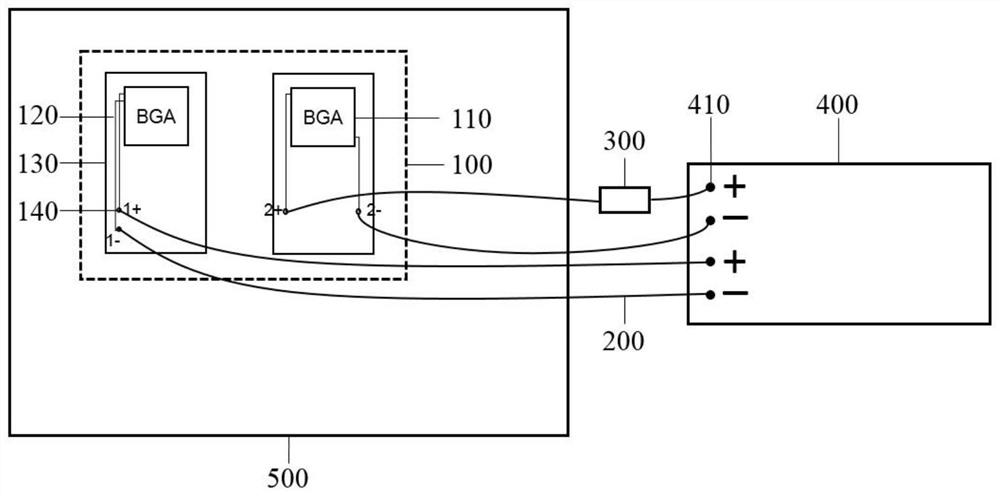

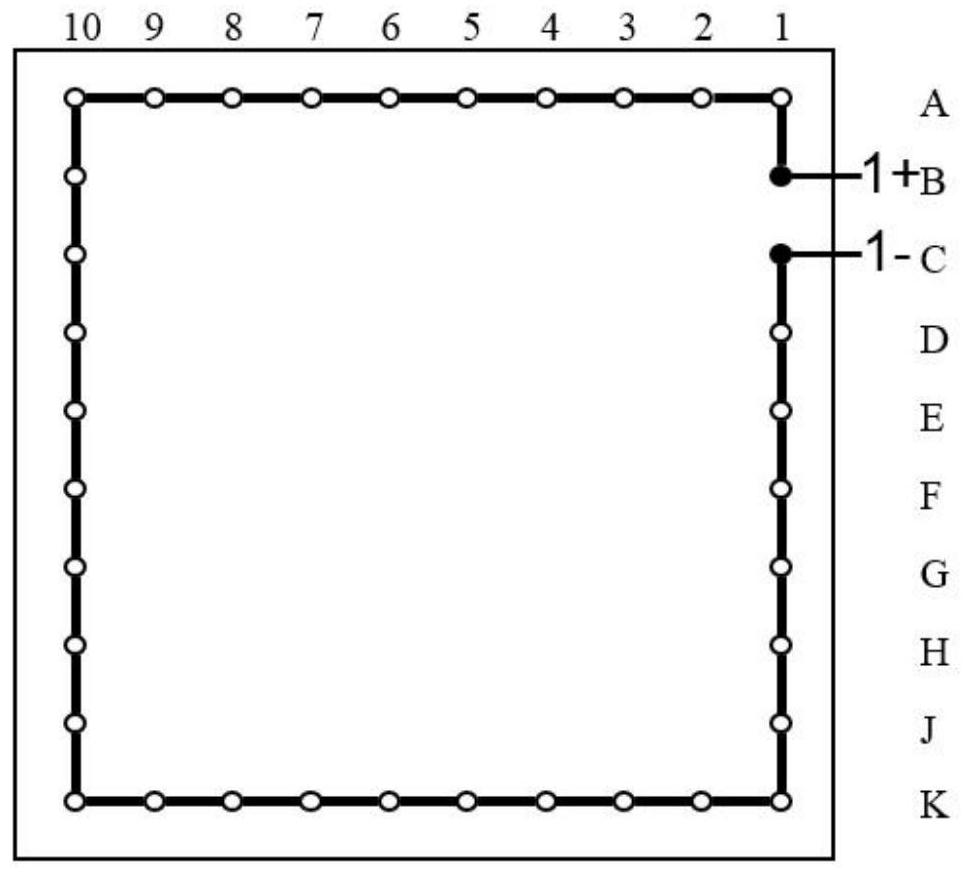

[0022] Connect the BGA package device 110 to the PCB substrate 130 through interconnection solder joints, connect the solder joints, design the BGA package into different samples 100 to be tested by leading out different test points, and connect the solder joints to the PCB substrate 130 through copper wires 120 The connecting terminal a140 on the top; the sample 100 to be tested is placed in the composite fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com