Manufacturing method of array substrate, array substrate and display panel

A technology of an array substrate and a manufacturing method, which is applied in the display field, can solve the problems of cracking of the protective layer, liquid crystal bubbles, rough particles, etc., and achieve the effect of improving the smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

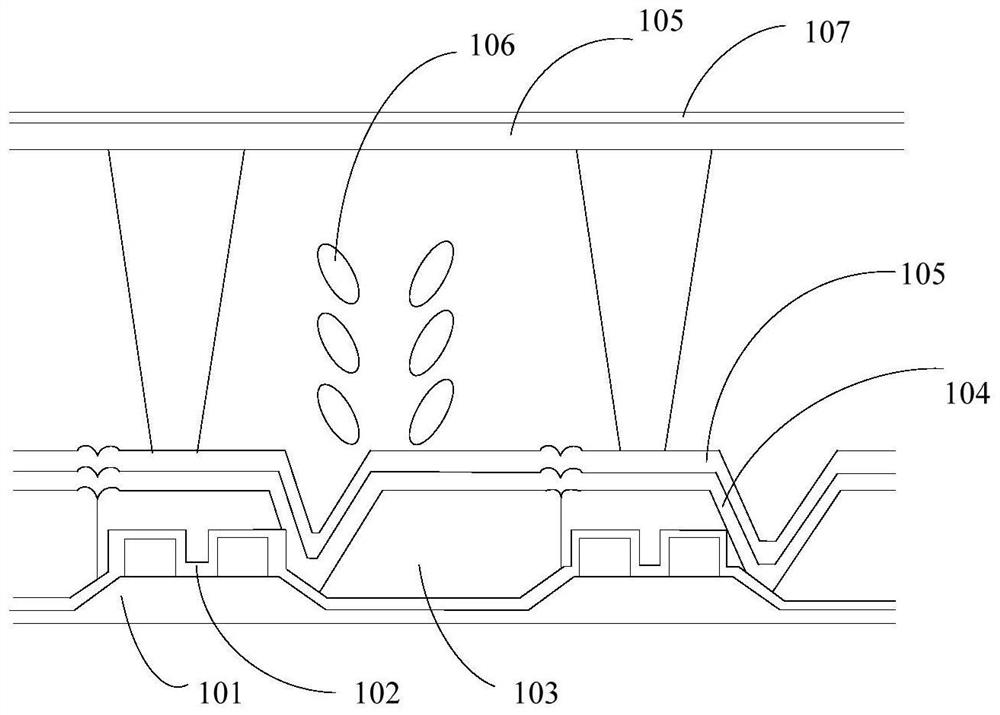

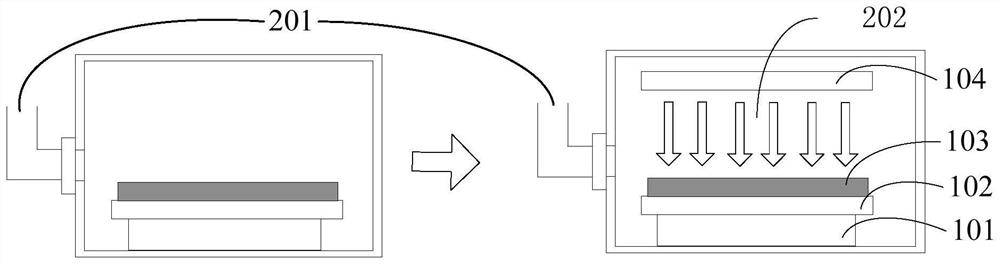

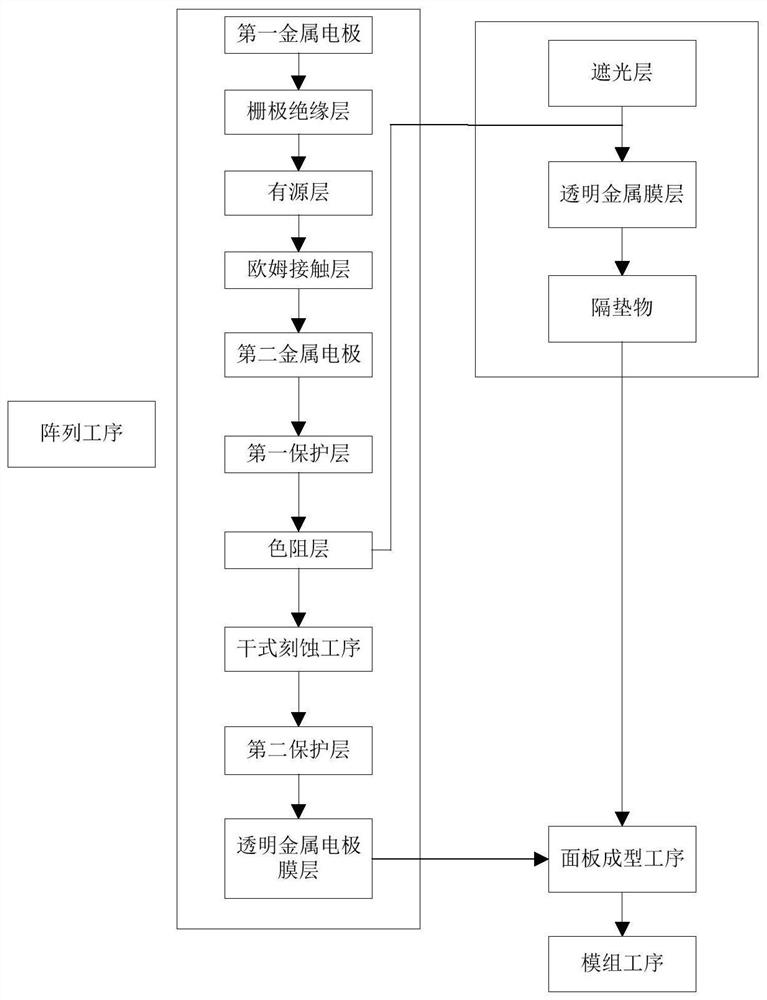

[0049] refer to Figure 4 , Figure 4 As the first embodiment of the manufacturing method of the array substrate of the present invention, the manufacturing method of the array substrate includes the following steps:

[0050] Step S10, coating a first protective layer on the thin film transistor substrate;

[0051] Optionally, the first protection layer may be silicon nitride material.

[0052] Step S20, forming a color resist layer on the first protective layer;

[0053] The thin film transistor substrate and the color resist layer are in a vacuum state;

[0054] Step S30, applying an alternating electric field with preset electric field parameters above the color-resist layer to eliminate particles on the surface of the color-resist layer;

[0055] The alternating electric field is generated by a radio frequency power supply; the color-resisting layer is the color-resisting layer, and the particles on the surface of the color-resisting layer include hydrocarbon-containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com