Bearing fault diagnosis method based on parameter optimization VMD and weighted Gini index

A Gini index and fault diagnosis technology, applied in geometric CAD, special data processing applications, instruments, etc., can solve problems such as significant impact on decomposition accuracy, difficulty in fault feature extraction, wide frequency spectrum of vibration signals, etc., and achieve good resistance to random pulse interference, Good ability, efficient and accurate extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

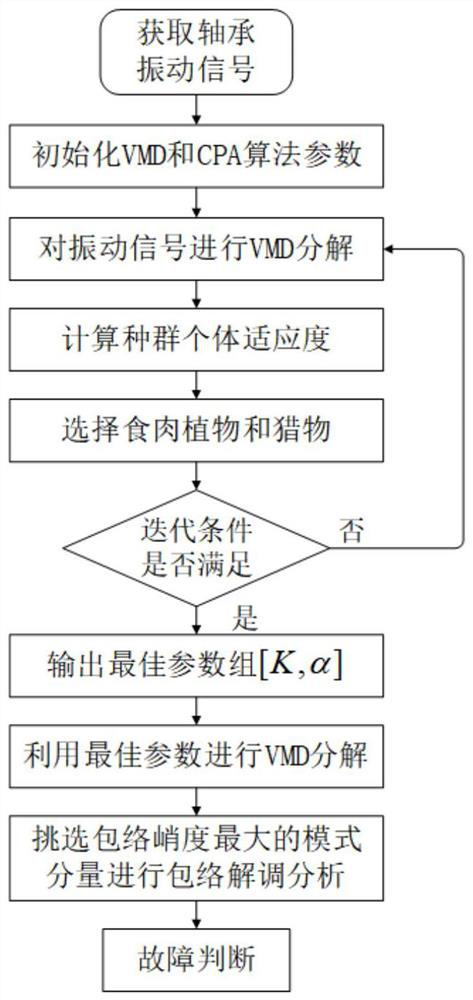

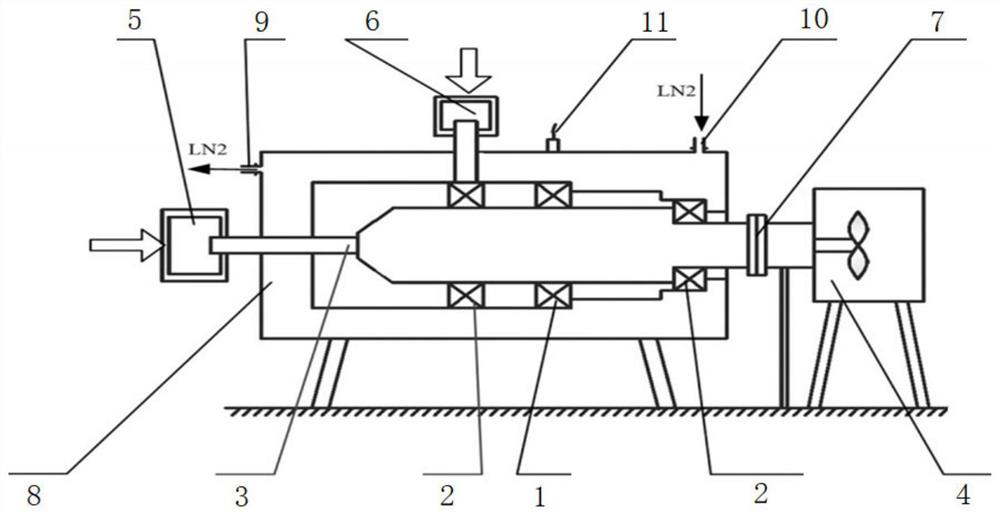

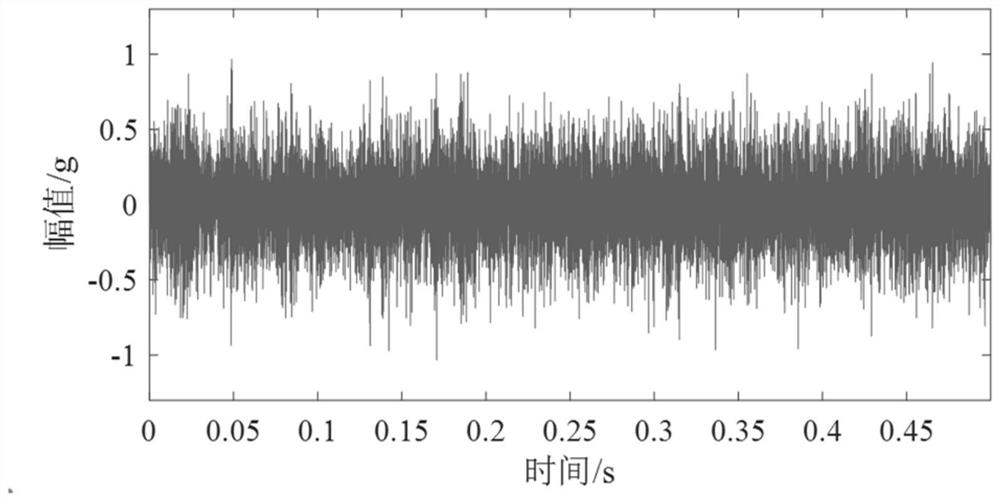

[0090] Car Meat Plant Optimization (CPA) Algorithm is a group element optimization algorithm for the growth and reproduction process of food plants, which can better balance the overall development and local exploration capabilities of algorithms, solve high-dimensional design variables, multiple constraints And there is a significant advantage over the problem of more local extremes. Therefore, the present invention has obtained the best VMD decomposition parameters by introducing the carnivorous plant optimization algorithm, and proposes a bearing fault diagnosis method based on parameter optimization VMD and a weighted Kini index. It can effectively reduce the influence of the parameter selection to VMD, and obtain the best decomposition. Effect, can extract periodic fault impact pulses to a strongly complex background noise, and realize the fault...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com