An inductance forming system and forming process

A technology of inductors and electromagnets, which is applied in the field of inductor forming systems and molding processes, can solve the problems of long manufacturing hours of inductors, generation of defective or waste products, cumbersome bending operations of inductors, etc., to improve the accuracy of grasping and facilitate grasping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

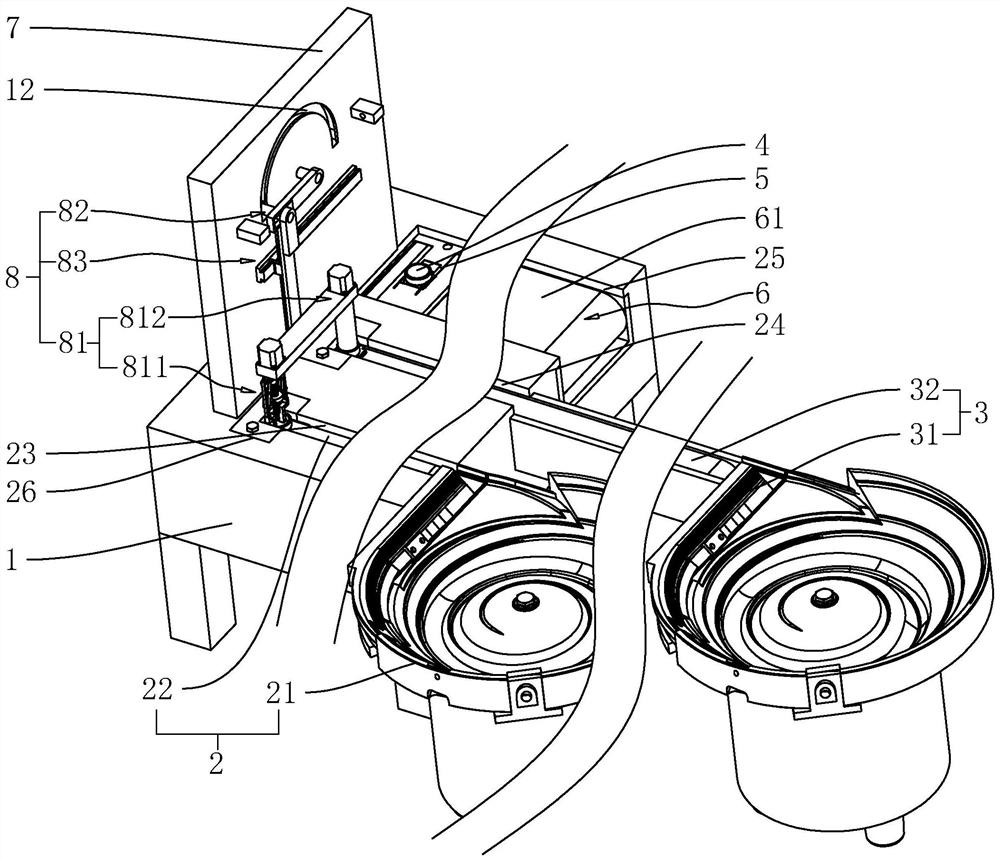

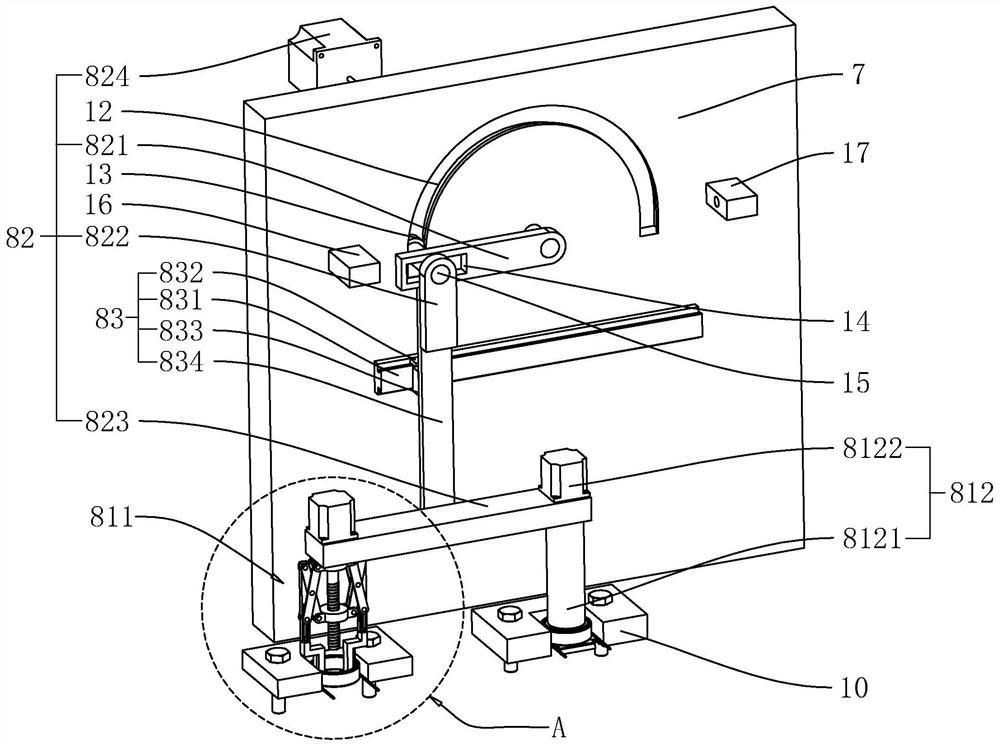

[0042] The following is attached Figure 1-4 The application is described in further detail.

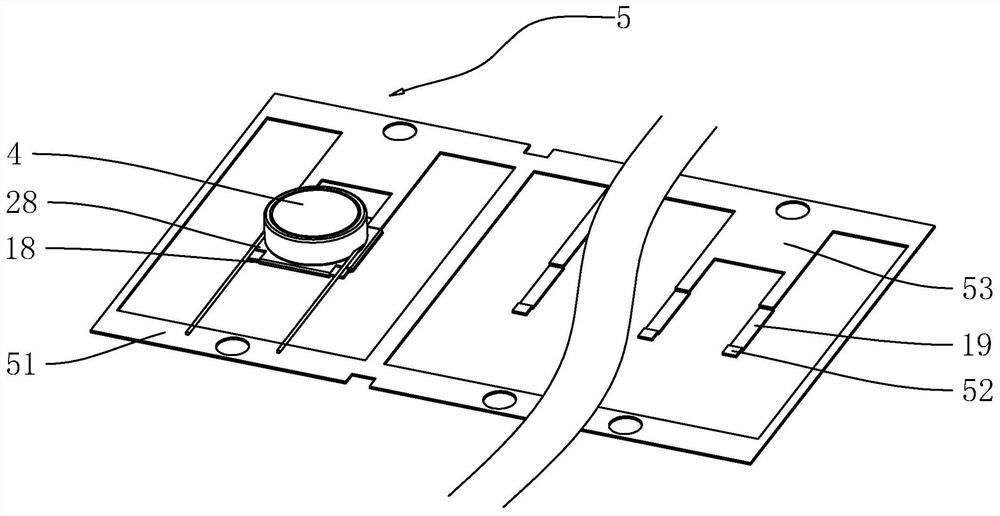

[0043] The embodiment of the present application discloses an inductance forming system. refer to figure 1 and figure 2 , the inductance forming system includes a machine 1 and a coil feeding mechanism 2 arranged on the machine 1, a T buckle feeding mechanism 3 and a carrier belt conveying mechanism 6. In this embodiment, the T buckle 28 is composed of a cross-shaped cross Composed of two bottom plates, the T buckle 28 is located on the top surface of the intersection of the two bottom plates and is fixedly connected with the center column 4 for the coil 27 to be sleeved. Compared with the traditional production process, the center column 4 is pressed during the powder molding process. The embodiment of the application adopts the prefabricated central column 4 with high density and uniformity, which can effectively improve the magnetic permeability of the inductor after forming; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com