Micro-power-consumption waterproof telemetering terminal

A terminal and waterproof technology, which is applied in the field of micro-power waterproof telemetry terminals, can solve the problems of clogged filter mechanism, reduced telemetry final working life, unfavorable monitoring screen clarity, etc., to ensure work safety and heat dissipation operations , to avoid the effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

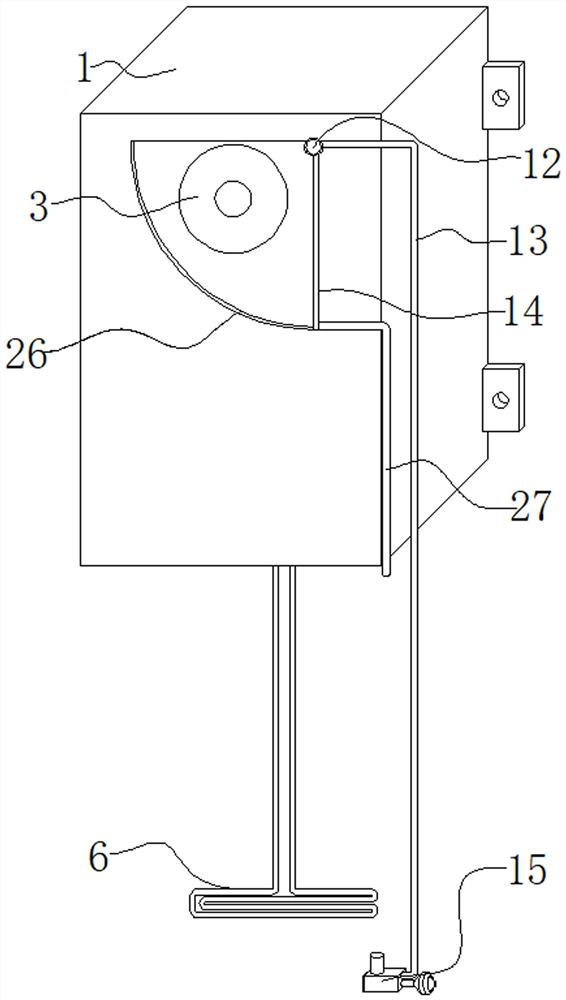

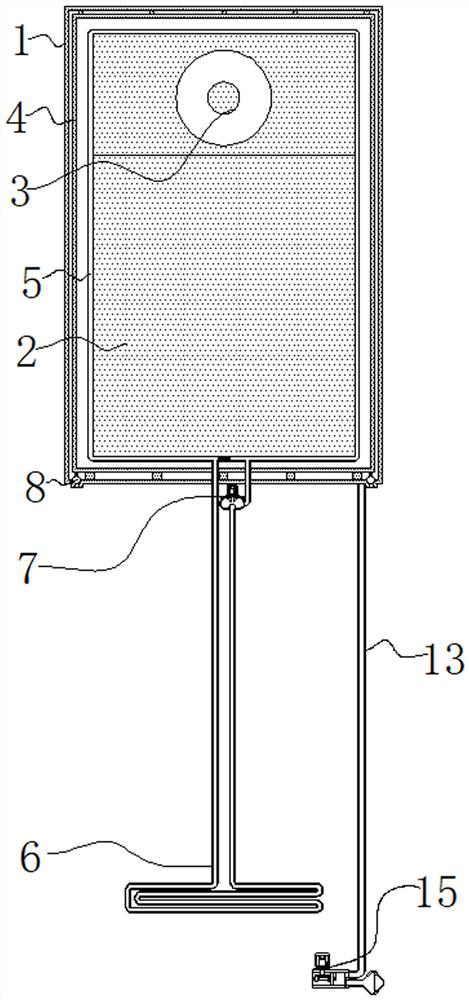

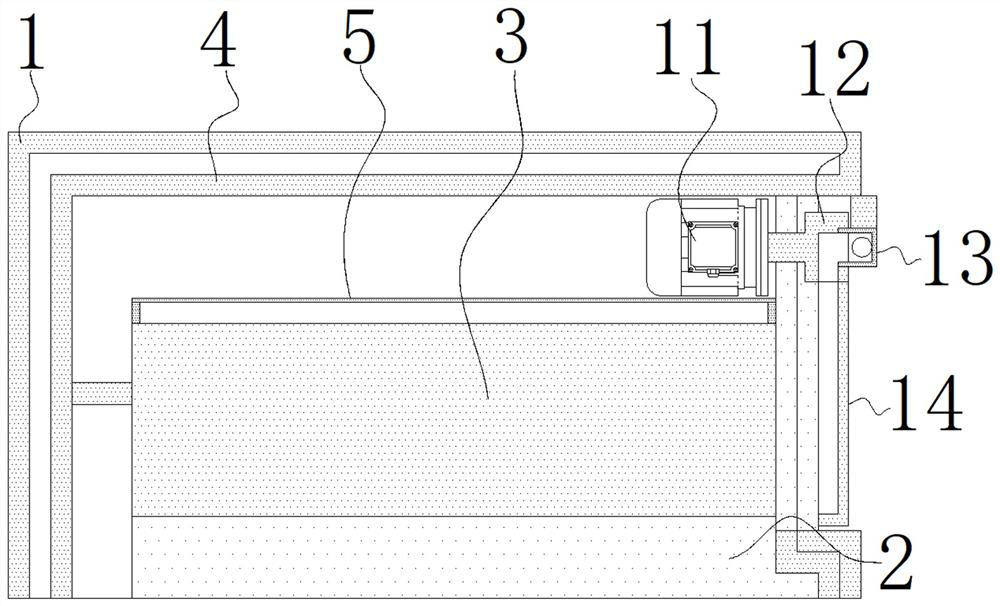

[0033] As a preferred embodiment of the present invention, one end of the ferrule 16 communicates with the bottom of the water pump 15, one side of the taper sleeve 17 is clamped with the inner side of the ferrule 16, and the other end of the taper sleeve 17 The side passes through the ferrule 16 and extends to the outside of the ferrule 16, the diameter of one side of the taper sleeve 17 is greater than the inner diameter of the other end of the ferrule 16, and one side of the taper sleeve 17 is welded to the filter screen by a pole 18 inside.

[0034] As a preferred embodiment of the present invention, one side of the water pump 2 15 is provided with an upper port and a lower port, and the flap 1 24 and the flap 2 25 are respectively installed on the inside of the lower port and the upper port through a rotating shaft, so that The connecting pipe 13 and the ferrule 16 are respectively welded on the outer sides of the upper port and the lower port.

[0035] As a preferred em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com