Nonwoven fabric and filter using same

A technology of non-woven fabrics and fibers, applied in the field of non-woven fabrics and filters, can solve the problems of reduced elasticity of non-woven fabrics, reduced air permeability, excessive increase in fiber density, etc., and achieves good processability, oil absorption and capture. high effect

Pending Publication Date: 2021-10-01

TOYO ALUMINUM EKCO PRODUCTS KK

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And, as mentioned above, if the fiber density is excessively increased, the air permeability may be reduced, and the elasticity of non-woven fabrics that become too strong and hard may be reduced.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0100] Hereinafter, the present invention will be specifically described based on examples. In addition, embodiment of this invention is not limited to an Example.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

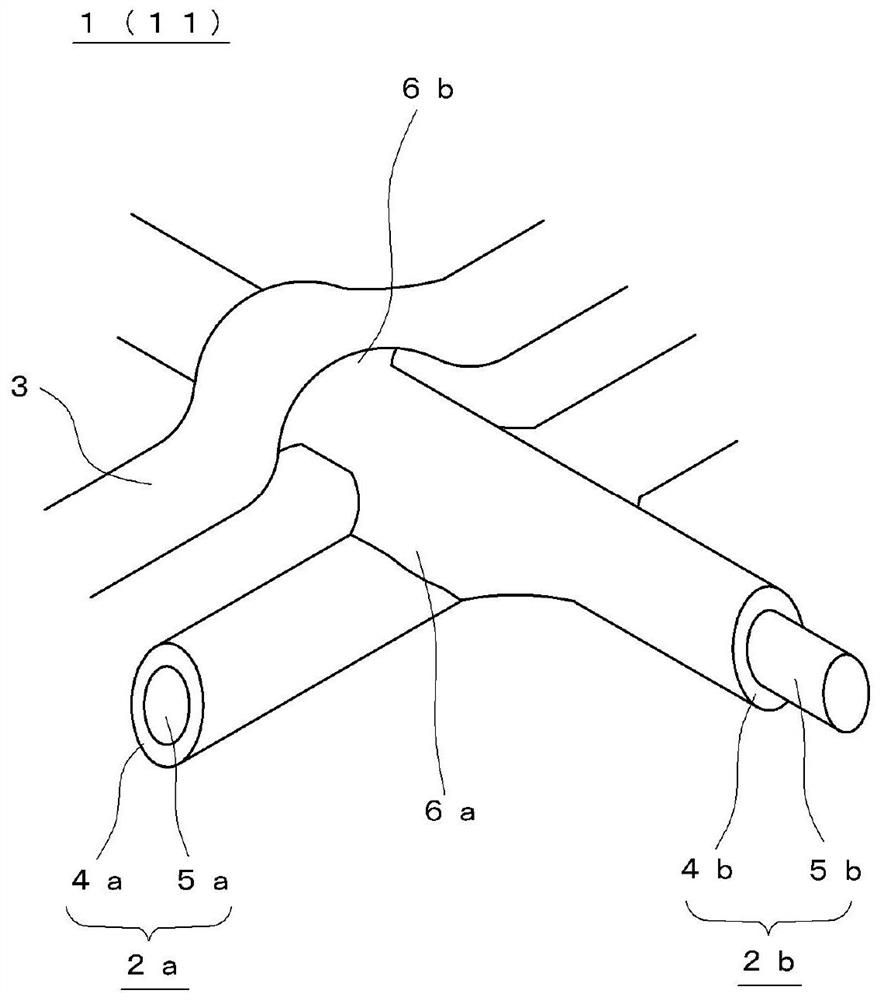

A nonwoven fabric main body (11) that constitute a nonwoven fabric (1) according to the present invention is composed by integrating composite polyester fibers (2) and flame-retardant acrylic fibers (3) which serve as other fibers making up the balance. The composite polyester fibers (2) have a sheath-core structure wherein a sheath part (4) is composed of a low-melting-point polyester and a core part (5) is composed of a high-melting-point polyester that has a higher melting point than the low-melting-point polyester. The composite polyester fibers (2) are contained in an amount of 15-80% by weight in a total of 100% by weight of the nonwoven fabric main body (11). The apparent density of the nonwoven fabric main body (11) ((weight of nonwoven fabric main body) / (thickness of nonwoven fabric main body)) is from 0.005 g / cm3 to 0.040 g / cm3. In addition, the bending resistance of the nonwoven fabric main body (11) in the flow direction of the fibers is 50-220 mN.cm, while the bending resistance in a direction that is orthogonal to the flow direction is 20-140 mN.cm.

Description

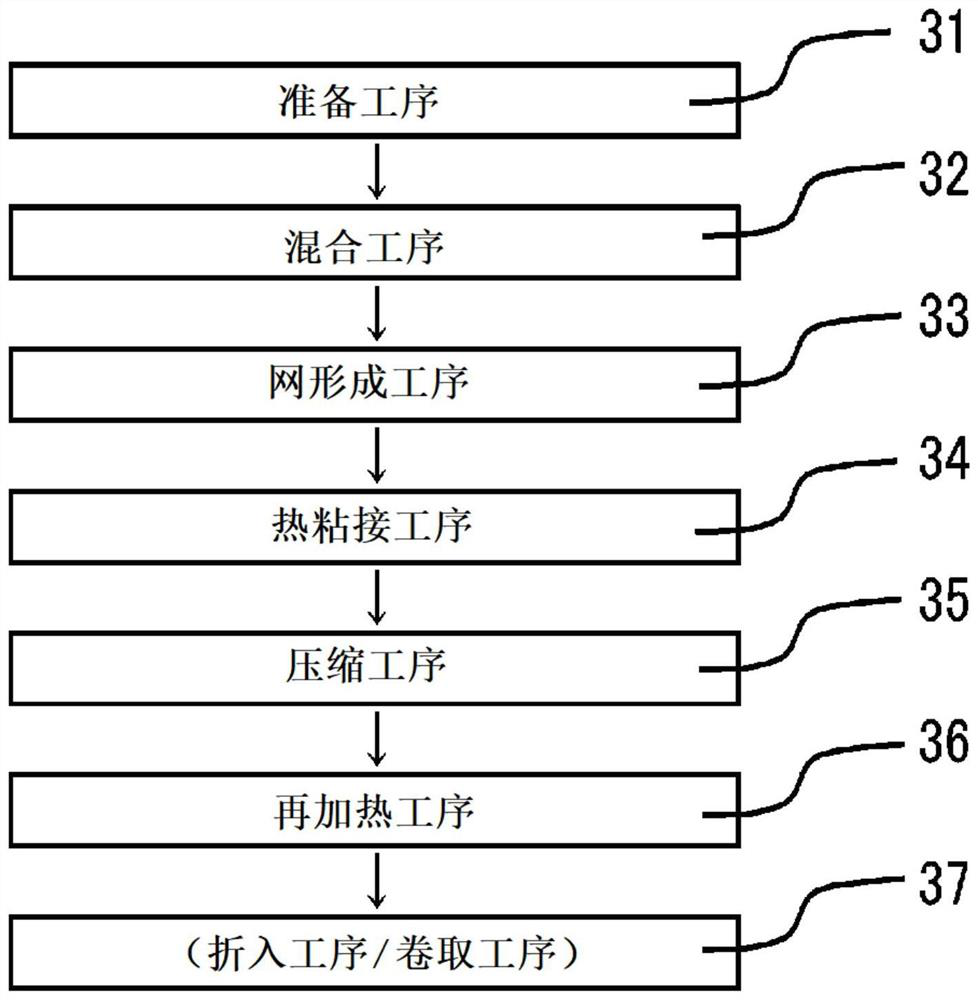

technical field [0001] The present invention relates to a non-woven fabric and a filter using the non-woven fabric, in particular to a non-woven fabric and a filter using the non-woven fabric for preventing pollution of range hoods, ventilation fans, air vents, etc. . Background technique [0002] Conventionally, nonwoven fabrics made of synthetic fibers have been used as filters for preventing contamination of range hoods and ventilating fans. [0003] For example, Japanese Patent Application Laid-Open No. 2003-236320 discloses a non-woven fabric and a filter using the non-woven fabric. After the fibers are mixed to form a fiber web (also called a web (card)), the fiber web is given a binder (adhesive, bonding agent) formed of a flame-retardant thermoplastic resin for bonding between fibers by using a sprayer or the like. ) to manufacture. A flame retardant such as a phosphorus-based water-soluble flame-retardant compound is added to the binder. When such a filter is use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D04H1/541B01D39/16B01D46/00D04H1/55F24F7/06

CPCB01D46/00D04H1/55F24F8/108D04H1/5412B01D2239/1291B01D2239/0457B01D39/163B01D2239/0233B01D2239/086D04H1/5418B01D39/1623B01D2239/0618B01D2239/1275

Inventor 足立将司山岸拓人

Owner TOYO ALUMINUM EKCO PRODUCTS KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com