Seat and packaging method thereof

A seat and seat technology, applied in packaging, transportation and packaging, chairs, etc., can solve the problems of large volume, large packing capacity, inconvenient seat transportation, etc., and achieve easy transportation, light weight, and economical placement. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

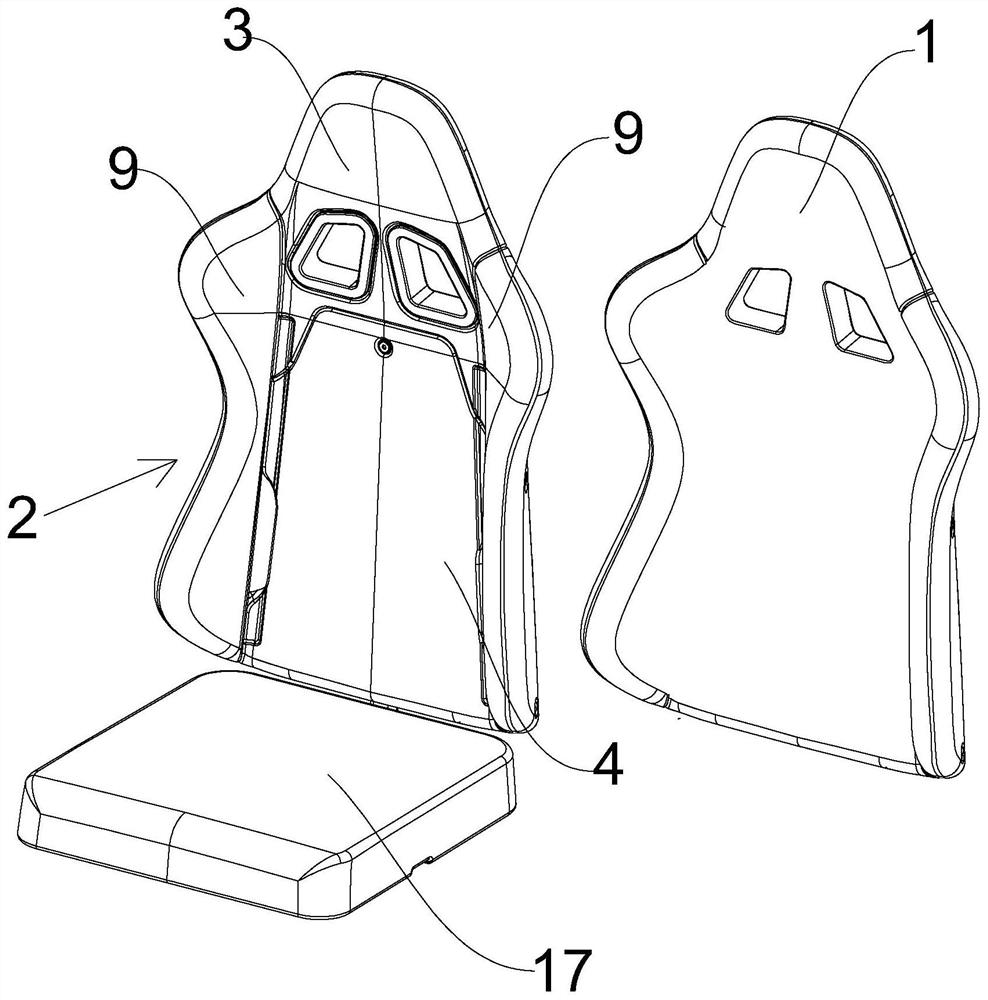

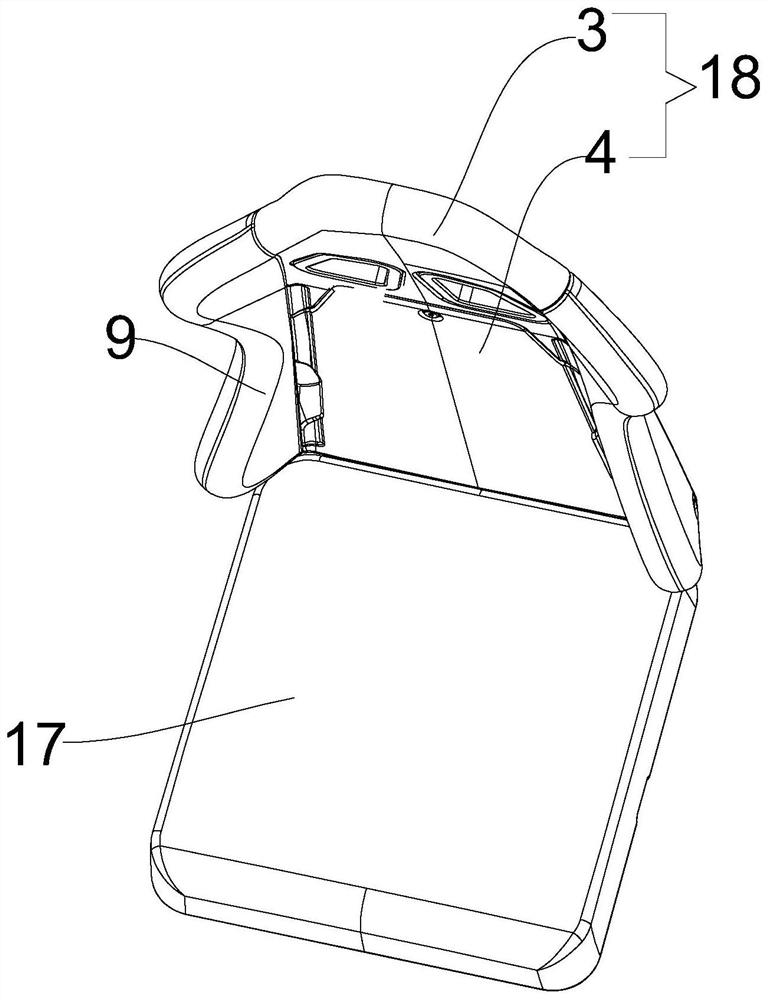

[0060] Embodiment 1: as Figure 1-12 As shown, the present invention provides a seat, including a cover 1, a base, a seat 17, a seat back 2 and a connecting bracket. Wherein the coat 1 is set on the outside of the chair back 2, and the coat 1 can be detached from the chair back main body 2.

[0061] In this solution, the seat back 2 includes a plurality of assembly modules, and the seat back 2 is formed by splicing and assembling the plurality of assembly modules. During transportation, multiple assembly modules can be disassembled and stacked, which greatly saves the placement space and facilitates transportation and transportation. And when it needs to be used, it only needs to assemble a plurality of assembly modules, which is convenient and can also bring a certain sense of accomplishment to the user.

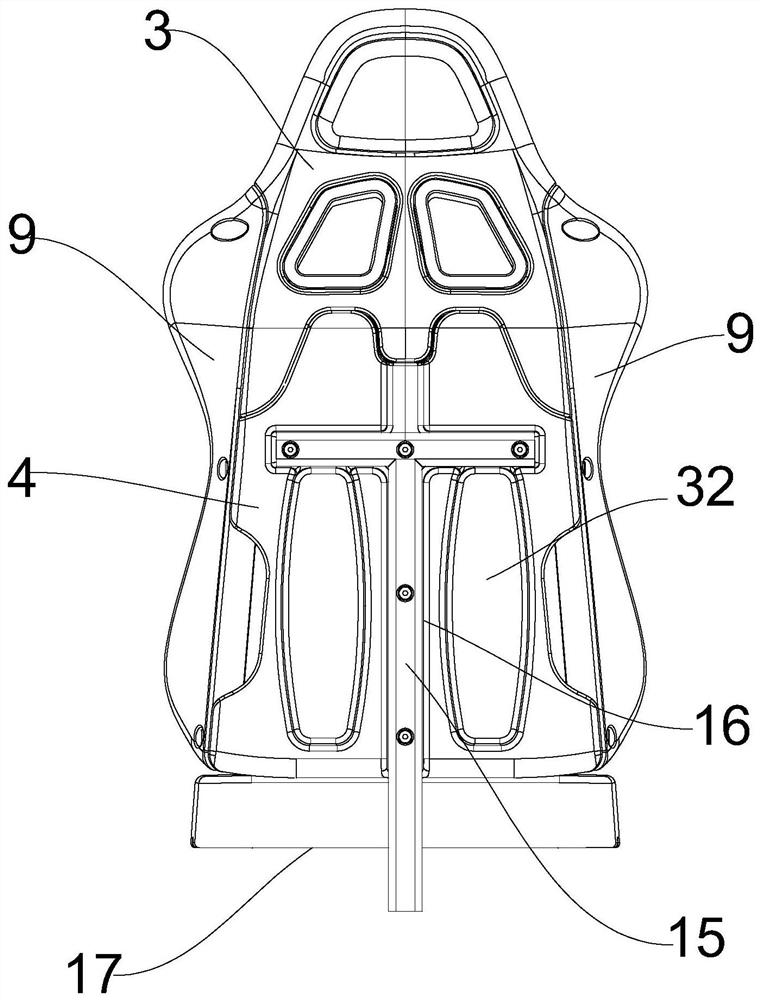

[0062] Specifically, see Figure 4 , Figure 7 and Figure 8 , the above-mentioned multiple assembly modules include an upper backplane 3 and a lower backplane 4, wher...

Embodiment 2

[0104] Embodiment 2: as Figure 13 As shown, the main difference between this embodiment and the seat in the above-mentioned embodiment 1 is that in this embodiment, the seat 17 is made by integral blow molding, and the bottom end surface of the seat 17 is provided with a connection area 33 and Storage area 31a. The chassis for connecting the connecting bracket 15 is detachably arranged on the connecting area 33 by screws. Moreover, the bottom end surface of the seat 17 is recessed toward the interior of the seat in the storage area 31 a to form a storage space 31 for placing other seat components in the seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com