Centering clamp for friction welding steel claw

A friction welding and centering fixture technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems affecting welding quality and efficiency, uneven distribution of clamping force, small clamping area, etc., to improve welding Uniform distribution of quality and clamping force, and the effect of reducing welding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

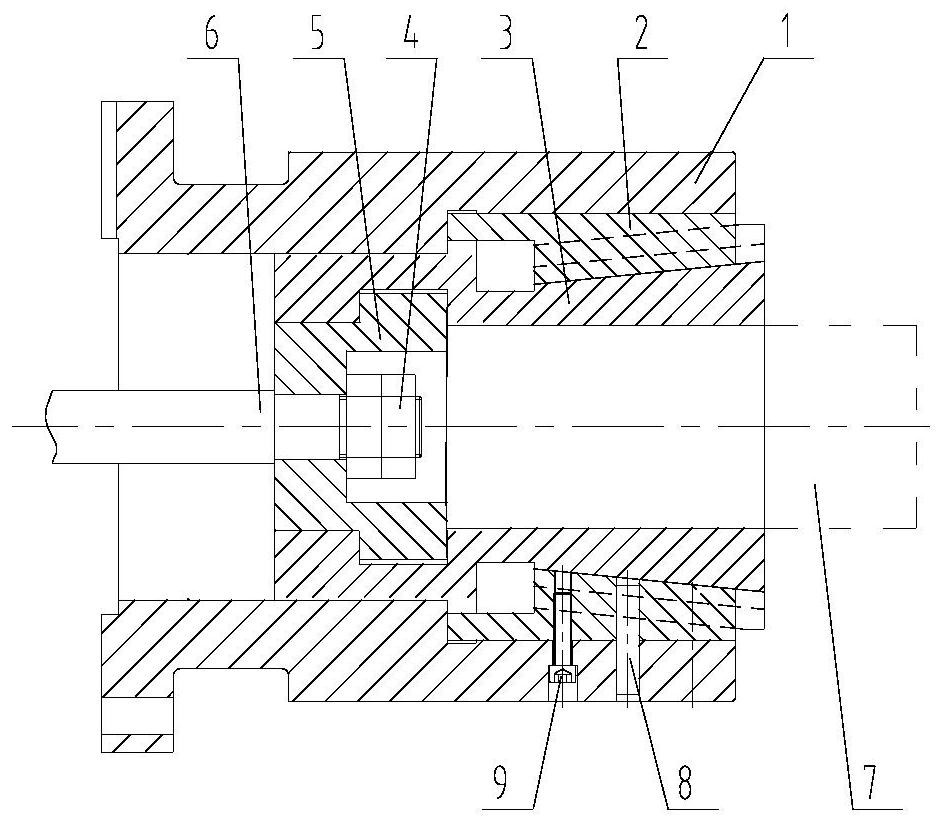

[0013] Such as figure 1 As shown, the centering fixture for friction welding steel claws includes: clamp body 1, steel claw sandwich core 3, pull rod 6, steel claw 7;

[0014] Before friction welding, the steel claw 7 is put into the inner hole of the clamp body 1, the right side wall of the steel claw sandwich core 3 has the same taper as the inner hole of the clamp body 1, and the inner surface formed by several steel claw sandwich cores 3 The surface of the hole is in contact with the outer circle of the steel claw 7, which plays the role of positioning and clamping at the same time when clamping; the left part of the steel claw sandwich 3 is connected to the pull rod 6, and the pull rod 6 is connected to the oil cylinder;

[0015] During welding, the steel claw sandwich core 3 moves to the left under the drive of the pull rod 6, and several steel claw sandwich cores 3 shrink and clamp the steel claws parallel to the center at the same time;

[0016] After the welding is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com