Manufacturing device and manufacturing method of asphalt polishing pad

A technology for making devices and polishing pads, used in grinding/polishing equipment, manufacturing tools, optical surface grinders, etc., can solve the problem of inability to take into account the flexible layer of the polishing disc, and achieve a smooth surface, uniform surface thickness, and mold release. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

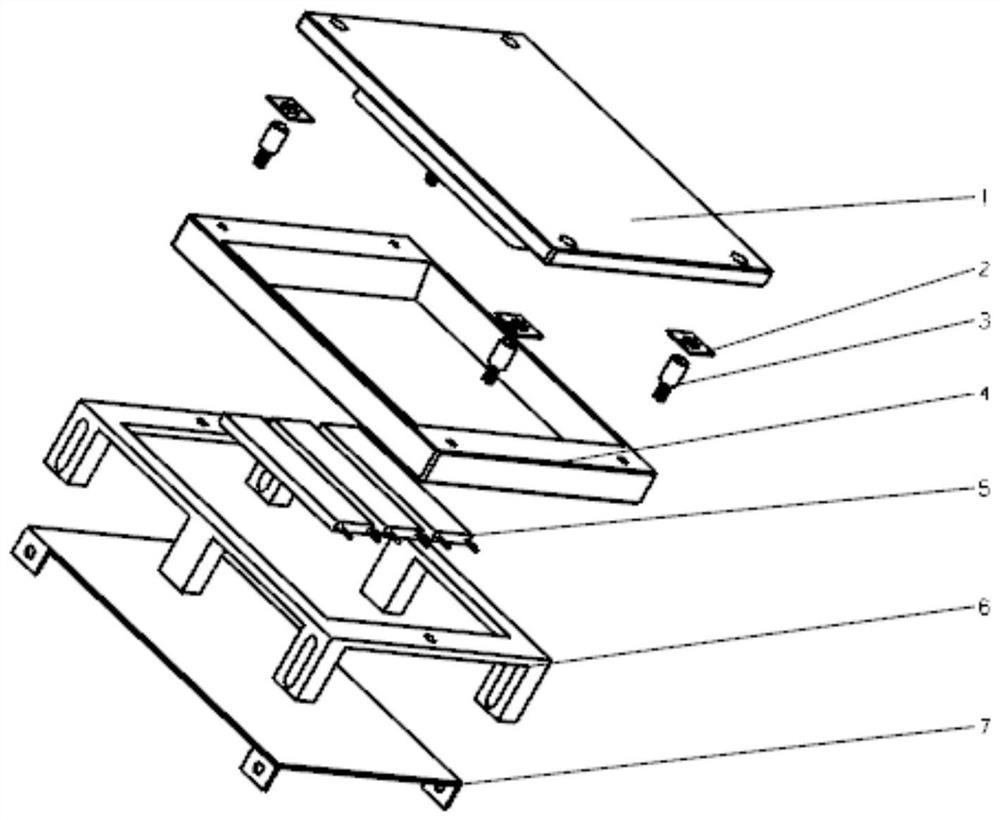

[0020] figure 1 An exploded view of the result of the production device for the asphalt polishing pad provided by Embodiment 1 of the present invention is shown. For ease of description, only the parts relevant to the embodiment of the present invention are shown, and the details are as follows:

[0021] On the one hand, the present invention provides a kind of asphalt polishing pad production device, comprise the pressing unit that arranges up to down sequentially, heating unit and support unit; Said pressing unit comprises: pressing plate 1, heating tank 4 and at least two positioning screws Column 3; the middle area of the bottom surface of the pressing plate 1 is provided with a terrace-shaped boss matching the shape of the heating tank 4; the edge of the heating tank 4 is provided with positioning screw holes, and the pressing plate 1 is positioned correspondingly The position of the screw hole is provided with a positioning hole; the lower half of the positioning stud ...

Embodiment 2

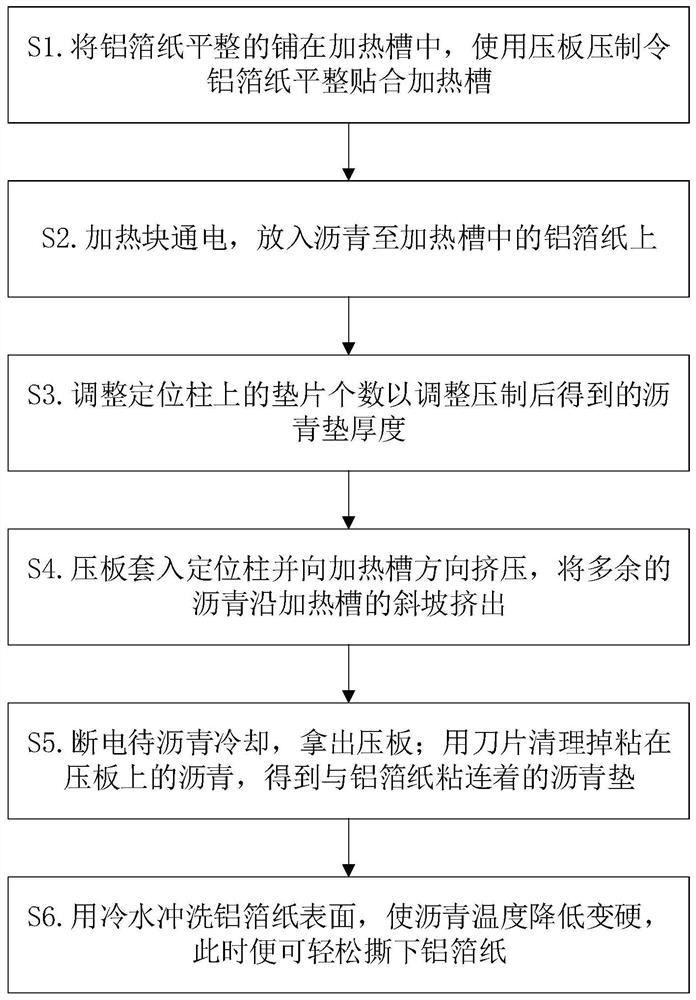

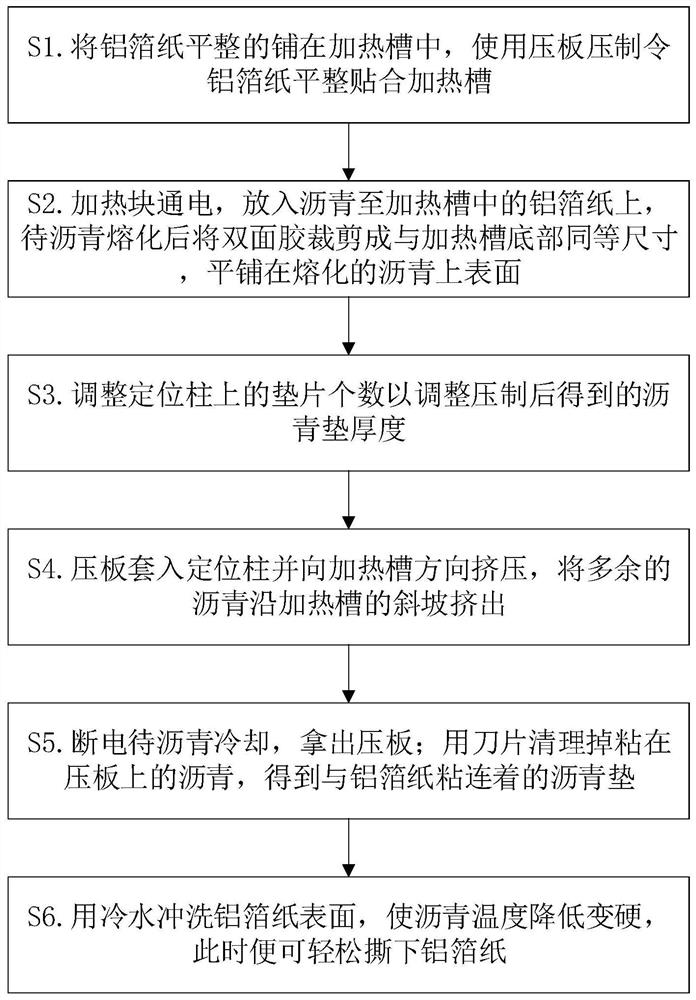

[0032] Figure 2-3 It shows the implementation flow of the asphalt polishing pad manufacturing method provided by the second embodiment of the present invention, and for the convenience of description, only the parts related to the embodiment of the present invention are shown.

[0033] as attached figure 2 Shown, the present invention also provides a kind of manufacture method of asphalt polishing pad, adopts as above-mentioned manufacture device; Described pressing method comprises the following steps:

[0034] S1. Spread the aluminum foil paper flatly in the heating tank 4, and use the pressing plate 1 to press it so that the aluminum foil paper fits the heating tank 4 flatly;

[0035] S2. The heating block 5 is energized, and the asphalt is placed on the aluminum foil in the heating tank 4;

[0036] S3. Adjust the number of 2 gaskets on the positioning column to adjust the thickness of the asphalt pad obtained after pressing;

[0037] S4. The pressing plate 1 is insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com