Variable angle mobile steel structure inclined beam hoisting adjustment support system and construction method

A technology of support system and construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

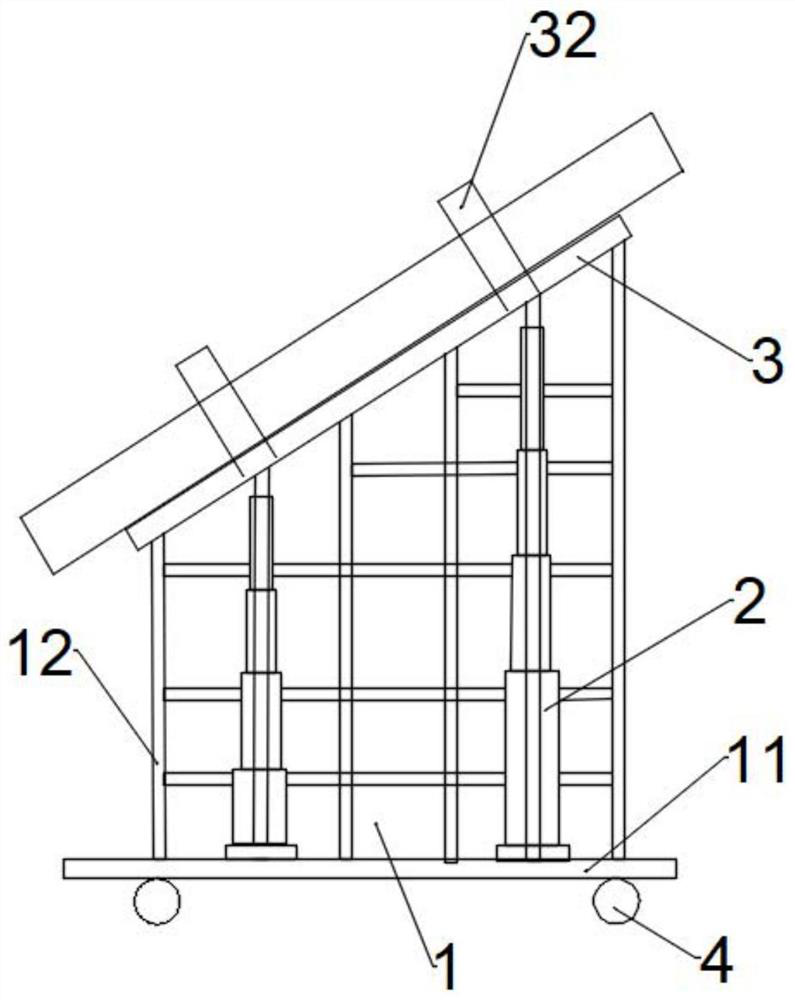

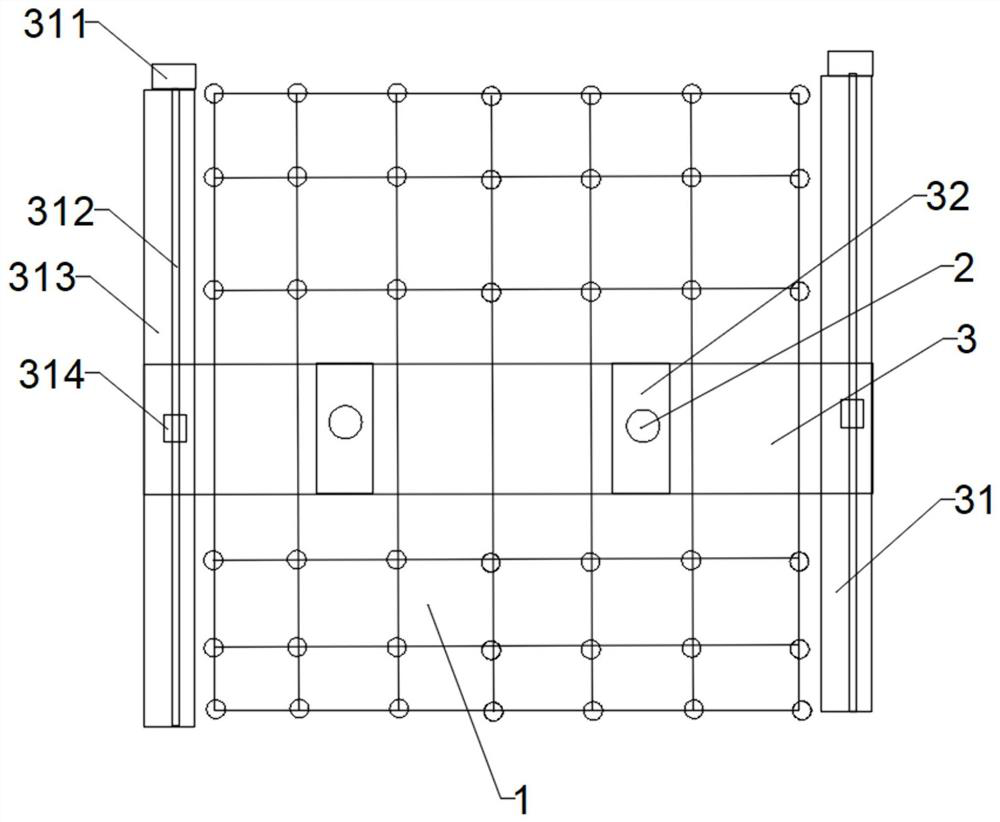

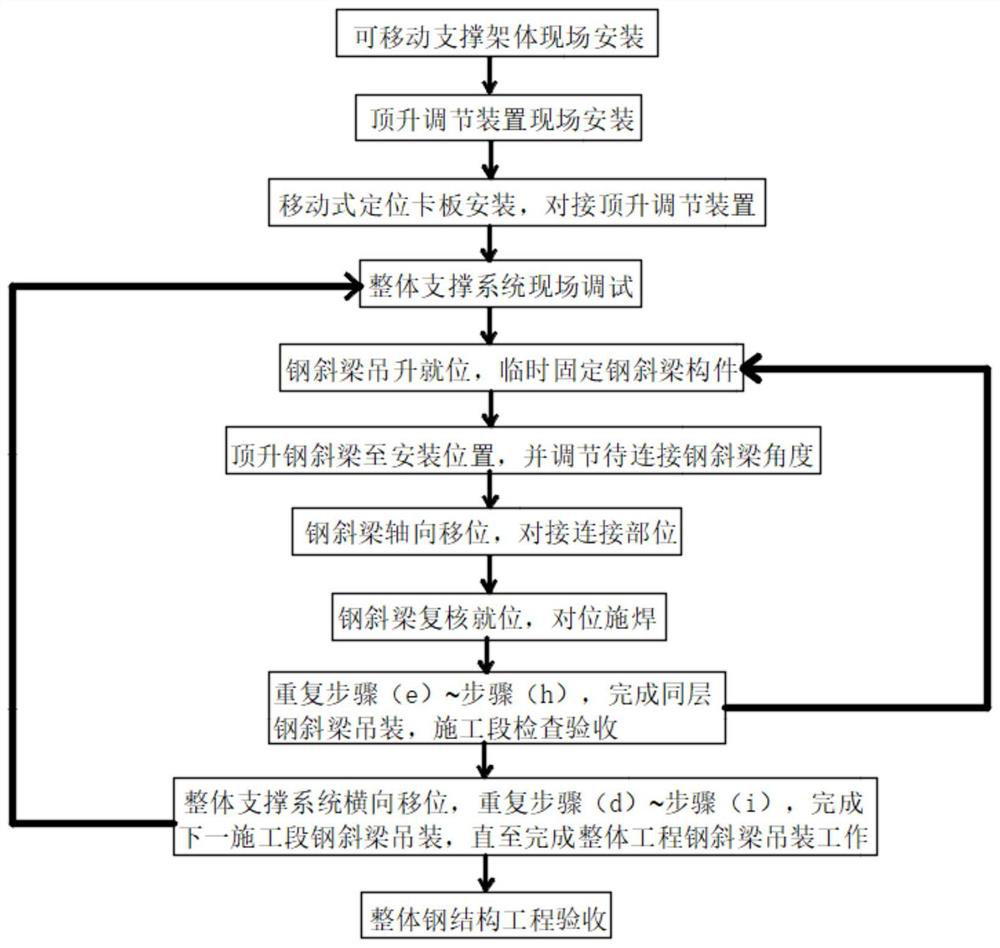

[0032] like Figure 1-Figure 3 As shown, the present invention provides a variable-angle movable steel structure inclined beam hoisting and adjusting support system, including a movable support frame 1, a lifting adjustment device 2 and a movable positioning card 3;

[0033] The movable support frame 1 is used for the support and hoisting of steel components in different construction sections, including a combined profiled steel base 11 and several vertical poles 12. The bottom of the vertical poles 12 is evenly installed on the surface of the combined profiled steel base 11 through a fixed latch device to ensure that the equipment The lower part of the combined section steel base 11 is provided with a traction pulley device 4, which is convenient for moving equipment and fixing;

[0034] The jacking adjustment device 2 is used to adjust the angle before the steel member is in place. It is located inside the movable support frame 1 and has an independent control system. In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com