Normal-temperature water catalysis hydrogen production method and equipment

A technology of hydrogen production equipment and room temperature water, applied in electrodes, cells, electrolysis process, etc., can solve the problem of not being able to be heated into water vapor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The normal temperature water catalytic hydrogen production method of the present embodiment comprises the following steps:

[0042] 1) Continuously heat the pyroelectric catalyst, and the heating temperature is about 90°C;

[0043] 2) During the continuous heating process of the pyroelectric catalytic element, spray water at about 20°C from the top or side of the reactor on the pyroelectric catalytic element to cause different parts of the pyroelectric catalytic element to generate Temperature difference and thermal fluctuations, so that the water in contact with the pyroelectric catalytic element dissociates to generate H 2 ; After the sprayed water flows through the tourmaline powder in the pyroelectric catalyst, the temperature will increase, and when it reaches a certain temperature, such as 70°C, it will leave from the bottom of the reaction vessel or the water outlet on the other side.

[0044] 3) collect the H produced in step 2) 2 ;

[0045] 4) Collect the wa...

Embodiment 2

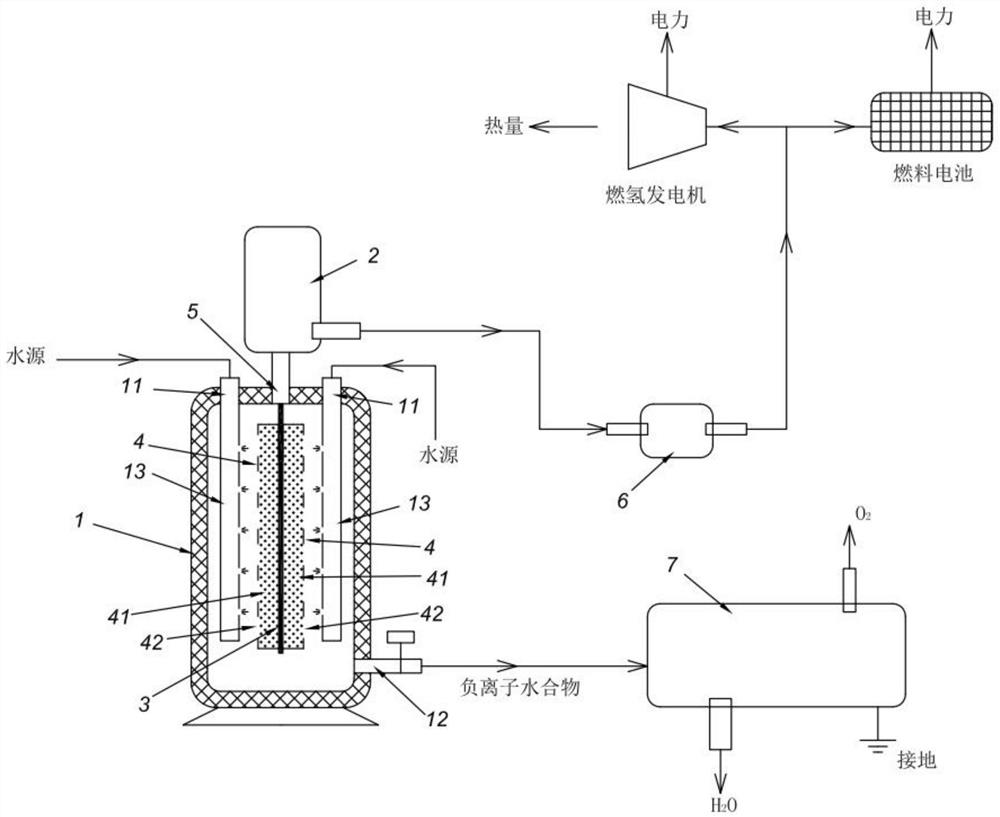

[0061] like figure 1 As shown, the room temperature water catalytic hydrogen production equipment in this implementation includes: a reaction vessel 1 , a condenser 2 , a heating component 3 and a pyroelectric catalytic component 4 . The heating element 3 wherein is an electric heating rod.

[0062] like figure 1 As shown, the reaction vessel 1 is provided with a water inlet 11 and a water outlet 12 . The water inlet 11 is arranged at the top of the reaction vessel 1 , and the water outlet 12 is arranged at the bottom of the reaction vessel 1 . The water inlet 11 communicates with the water nozzle 13 , and the water nozzle 13 finely and evenly sprays the water onto the pyroelectric catalytic element 4 . The heat-generating components 3 are distributed inside the reaction vessel 1 , and several pyroelectric catalytic elements 4 made into rods are installed around the outer circumference of the heat-generating components 3 . The pyroelectric catalytic element 4 of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com