Self-leveling assembled steel-concrete composite track structure

A self-leveling and concrete technology, applied in the field of rail transit, can solve the problems of poor track structure stability and service life, weak lower support structure and environmental capabilities, and difficult maintenance and repair of track slabs, so as to achieve less material waste and less trouble Hidden dangers of construction quality and the effect of maintaining the quality of track structure

Active Publication Date: 2022-06-03

NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The invention provides a self-leveling assembled steel-concrete composite track structure to solve the problem of large wet work workload and poor quality stability during the construction of the existing ballastless track structure; Weak environmental performance; prone to interface damage, poor stability and service life of the track structure during service; technical problems such as difficult maintenance and repair of track slabs, and difficulty in replacement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

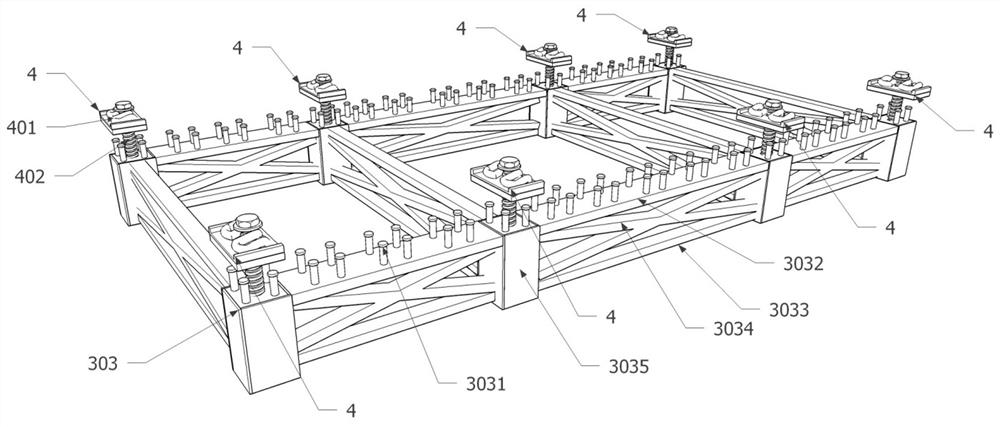

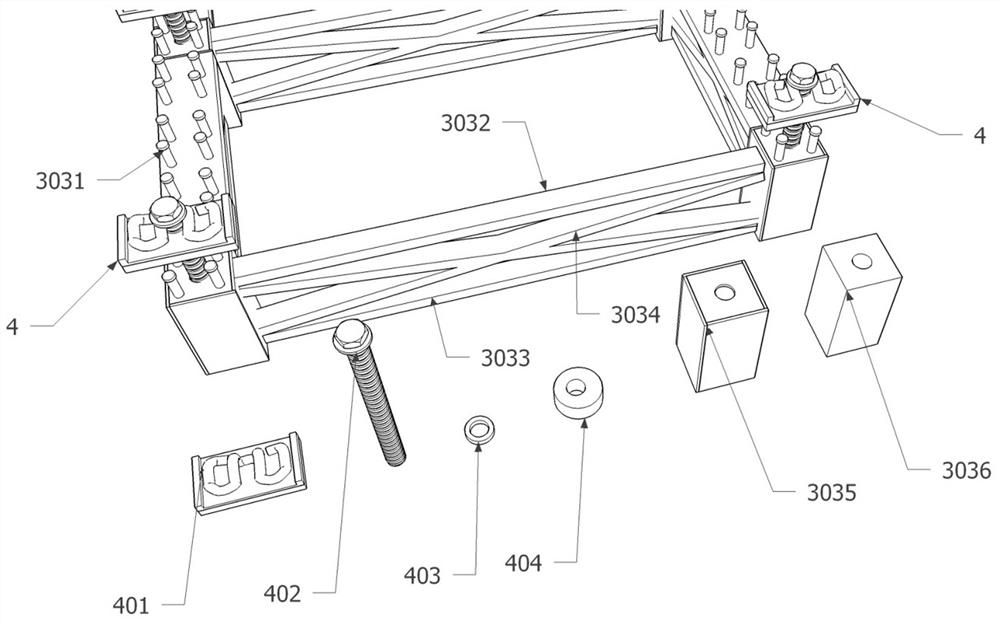

[0054] In this optional solution, the rail plate 302 and the rail bearing platform 301 are prefabricated by the factory, which is simple to process and has high manufacturing precision.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

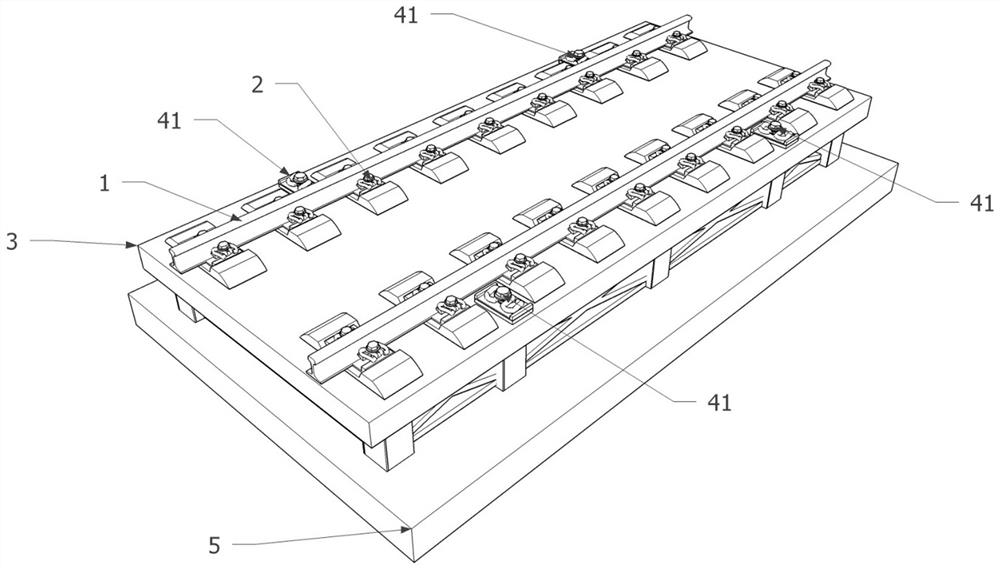

The invention discloses a self-leveling assembled steel-concrete composite track structure, which comprises: a base plate formed on a supporting foundation by on-site casting, and a factory prefabricated steel-concrete track unit is arranged on the base plate. The self-leveling assembled steel-concrete composite track structure also includes a self-leveling buckle anchor system, the lower end of which is embedded in the base plate, and the upper end protrudes through the prefabricated steel-concrete track unit to connect the base plate and The prefabricated steel-concrete track units are connected into a detachable monolithic structure, and the fabricated steel-concrete composite track structure is leveled. In the structure of the present invention, the track plate adopts a steel-concrete composite structure, the overall structure is stable, the structure interface is less, the disease is less, and it is easy to maintain; the self-leveling buckle and anchor system can be adjusted in a large amount, and the ability to adapt to the lower support structure and the environment is strong, especially It is suitable for laying on large-deformation support structures such as long-span bridges.

Description

Self-levelling fabricated steel-concrete composite track structure technical field The present invention relates to the technical field of rail transit, in particular, to a kind of self-leveling assembled steel-concrete composite rail Road structure. Background technique [0002] The development of my country's high-speed rail technology has grown from scratch, from weak to strong, and has gone through four stages. After more than 20 years of continuous efforts China has become the world's high-speed rail system with the most complete technology, the strongest innovation capability, the longest operating mileage, and the fastest operating speed. Fast, under construction The largest country. By the end of 2020, the operating mileage of my country's high-speed railways has exceeded 35,000 kilometers. "Medium and Long-Term Railway Network Planning (2016)" and "Twelfth Five-Year Plan for Comprehensive Transportation System", my country will continue to A certain scale o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01B1/00E01B3/46

CPCE01B1/002E01B1/004E01B1/005E01B1/007E01B2/00E01B2/003E01B2201/04E01B2204/09E01B2204/15

Inventor 余志武谈遂元强宋力伍军

Owner NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com