Ceramic tile paving method and automatic ceramic tile paving control system

A ceramic tile and paving technology, which is applied in the direction of construction and building construction, can solve the problems of ceramic tile paving position accuracy, difficulty in ensuring smoothness, high labor intensity, and tediousness, so as to reduce the probability of construction safety accidents and improve The effect of improving work efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0118] The technical solutions and technical effects of the present invention will be further described in detail below in conjunction with the accompanying drawings of the present invention.

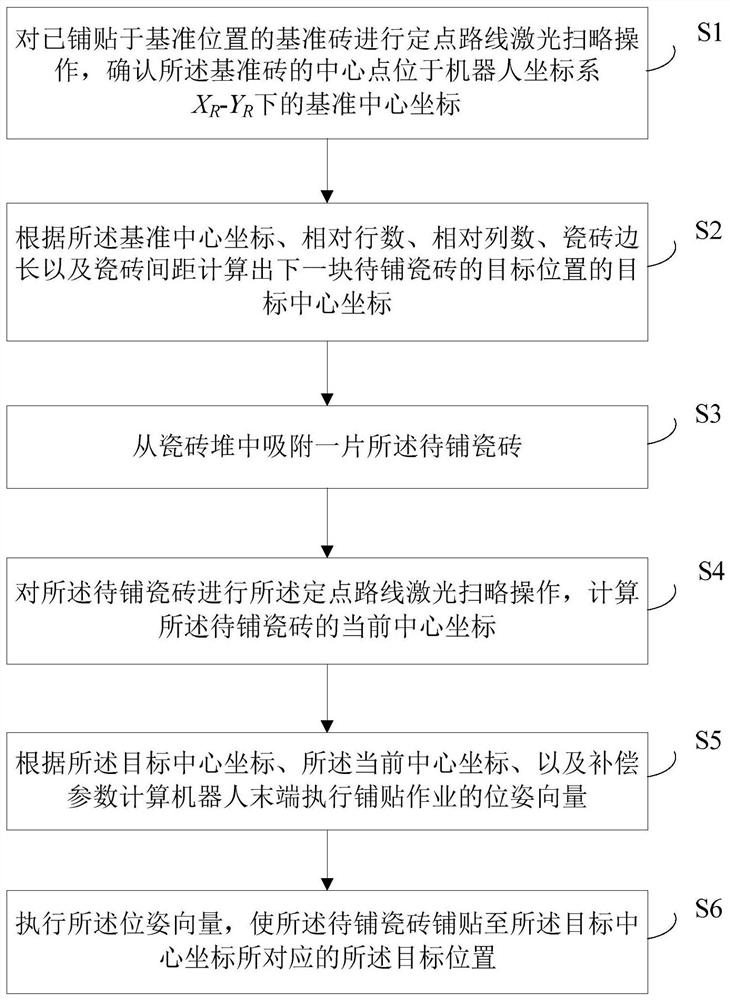

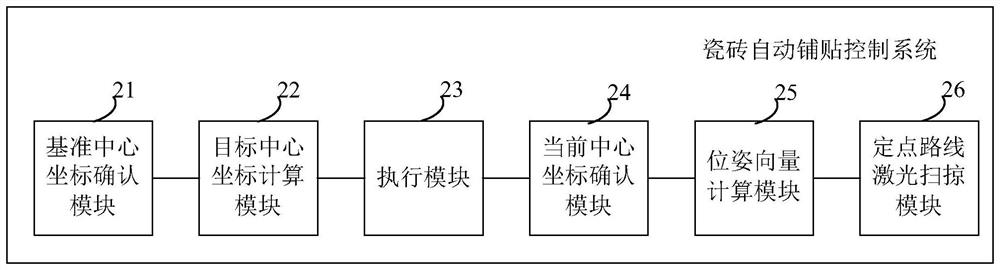

[0119] The present invention provides a ceramic tile laying and pasting method. Through the mechanical arm and the automatic tile laying and pasting control system, only one tile is used as a reference to perform the paving and pasting operation, such as figure 1 As shown, it specifically includes the following steps:

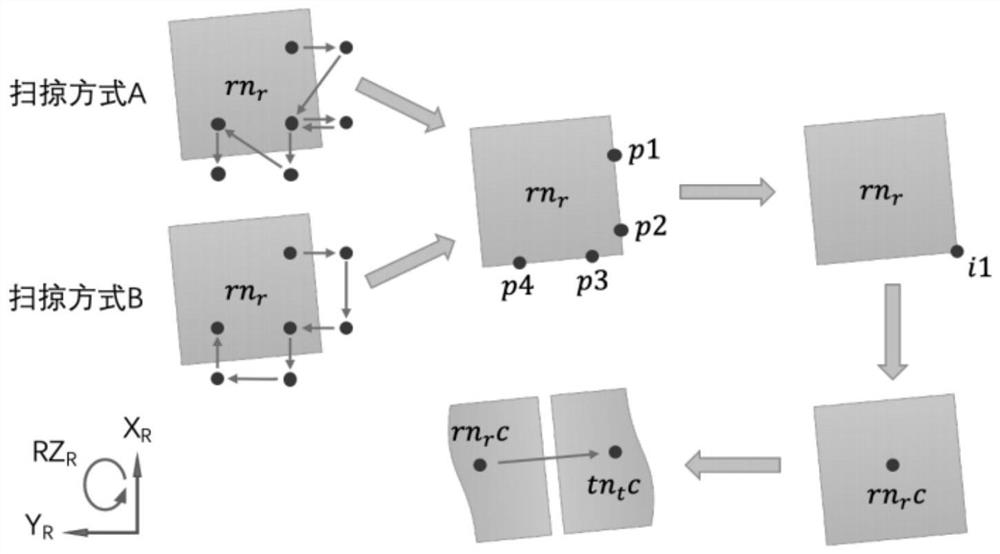

[0120] Step S1, for the reference brick rn that has been pasted at the reference position r Carry out the laser sweep operation of the fixed-point route to confirm the reference brick rn r The center point of is located in the robot coordinate system XR -Y R Datum center coordinates under

[0121] Step S2, according to the datum center coordinates Relative number of rows Relative number of columns tile side length a t and the tile spacing w g Calculate the n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap