Formwork erecting method for parapet wall

A form support method and parapet technology, applied in the field of formwork/formwork/work frame, preparation of building components on site, connectors of formwork/formwork/work frame, etc., can solve the inconvenience of parapet formwork support, The construction period is long, and the parapet wall is prone to water seepage and other problems, so as to achieve the effect of reliable formwork support system, saving construction period and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The formwork support method for parapet wall of the present invention, the parapet formwork installation construction plan is compiled before construction, the formwork position, back corrugated spacing, steel pipe spacing, the fixed position of the pull screw and the diagonal brace fixing method are determined according to the plan, and the formwork support method for the parapet wall Include the following steps:

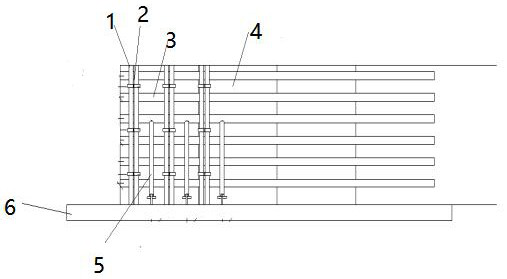

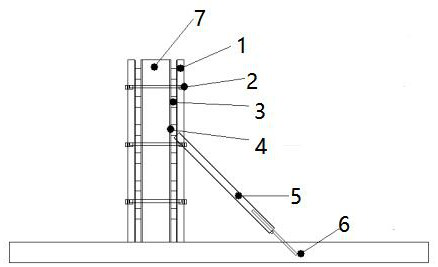

[0028] a. After positioning and setting out, place the template 4 and steel pipe 1 at the predetermined position; please refer to figure 1 and figure 2 , figure 1 is a schematic diagram of the template architecture of the embodiment of the present invention, figure 2 for figure 1 side view.

[0029] b. Place a number of square logs 3 horizontally connected to the whole length as a back corrugated. The first step of the square log is ≤200mm from the bottom of the formwork, and one step of square timber is placed at an interval of 200mm upward, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com