Invisible floor drain

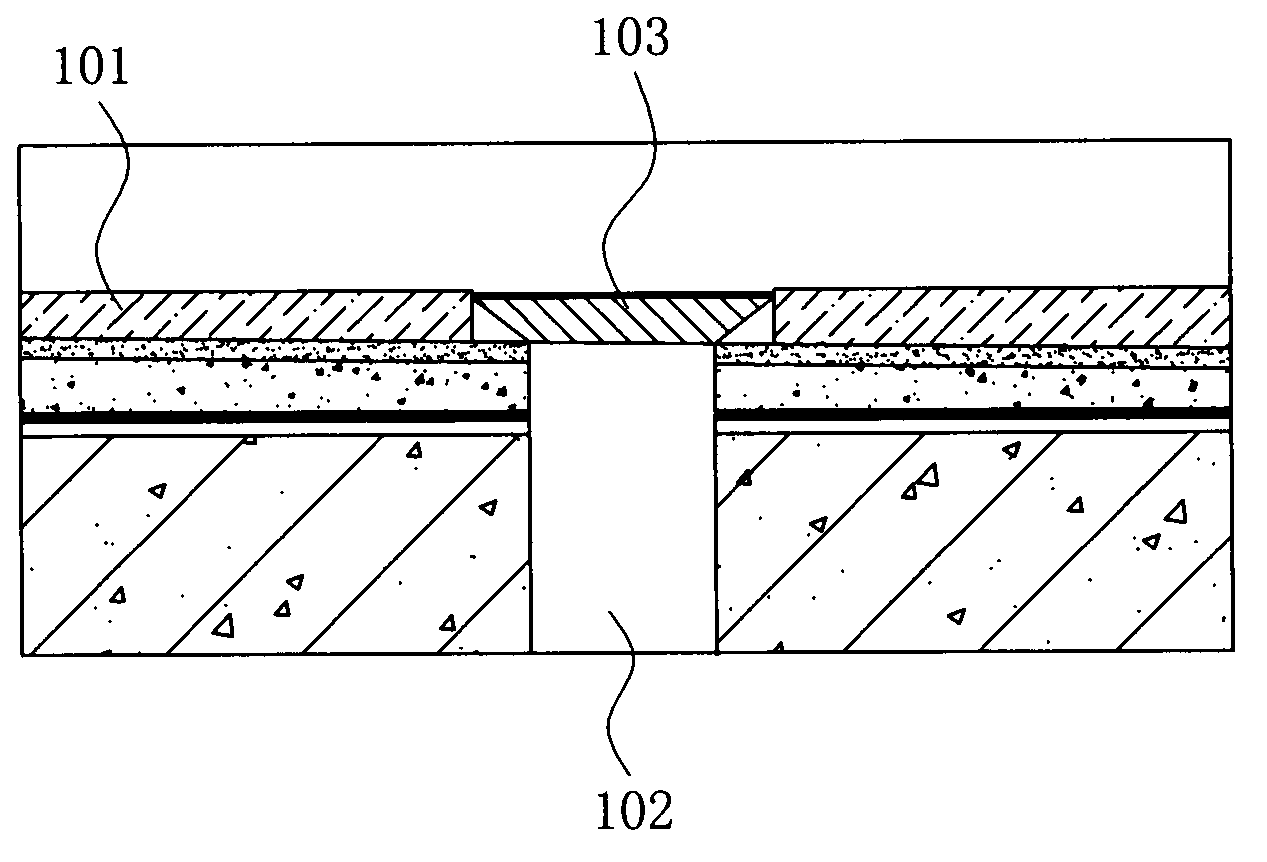

A floor drain, invisible technology, applied in the direction of indoor sanitary pipe installations, waterway systems, drainage structures, etc., can solve the problems of many processes, waste of materials, time-consuming, etc., to reduce environmental pollution, improve bearing capacity, and smooth drainage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

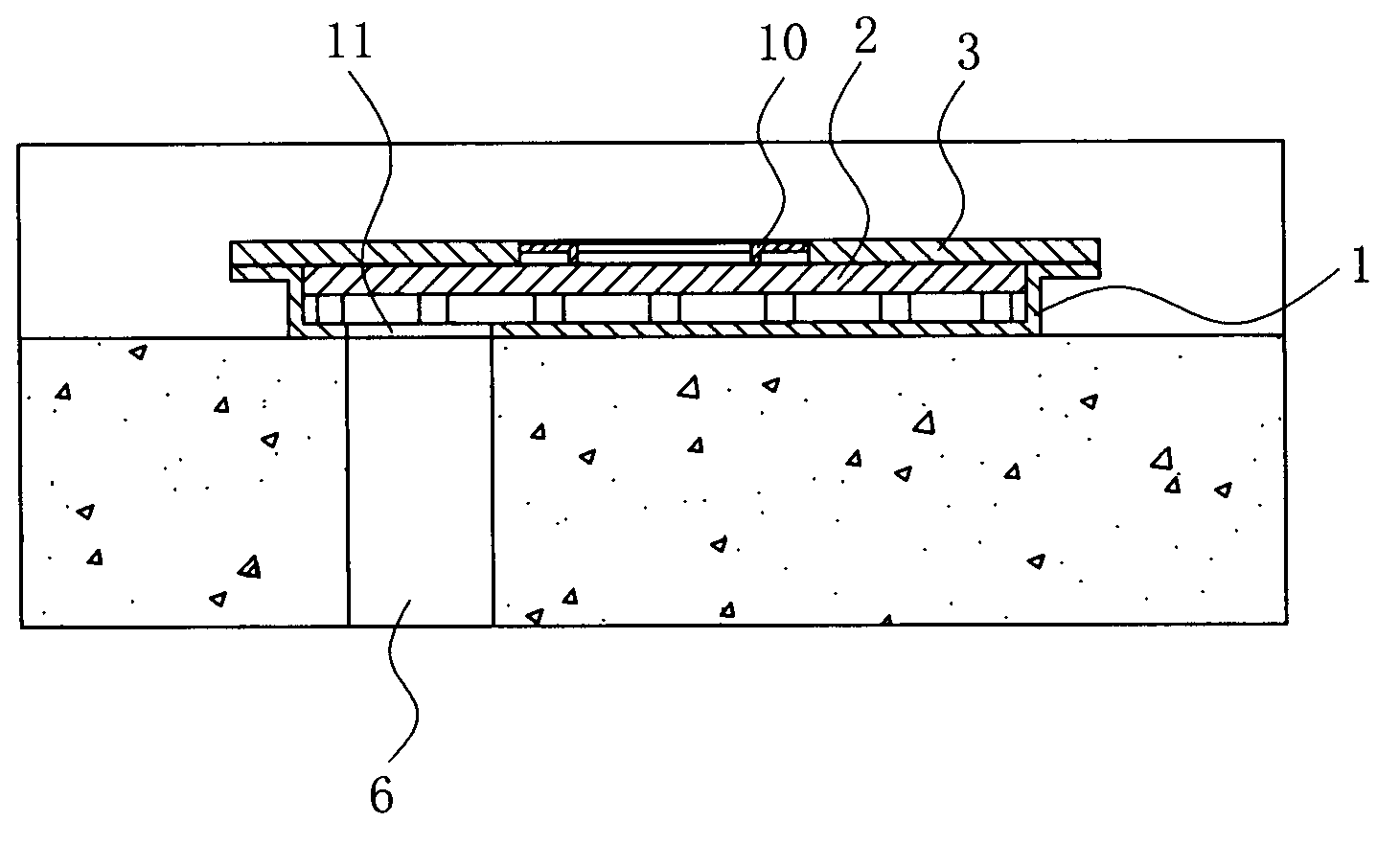

[0038] Embodiment one: see Figure 2-7 As shown, an invisible floor drain includes a base 1, a grid overhead layer 2 arranged in the base 1, and a surface material plate 3 arranged on the base 1, and the base 1 is integrally formed of PVC structure, the peripheral size of the base 1 matches the size of the surface material plate 3, the base 1 is composed of a concave base 4 and a flange 5 arranged on the outer edge of the concave base 4, and the concave base 4 corresponds to There is a drain hole 11 at the 6 places of the drain pipe, and the interface between the drain hole 11 and the drain pipe 6 is sealed with sealant, and the flange 5 on the outer edge of the concave base 4 can be used to support the surface plate 3 as load-bearing side.

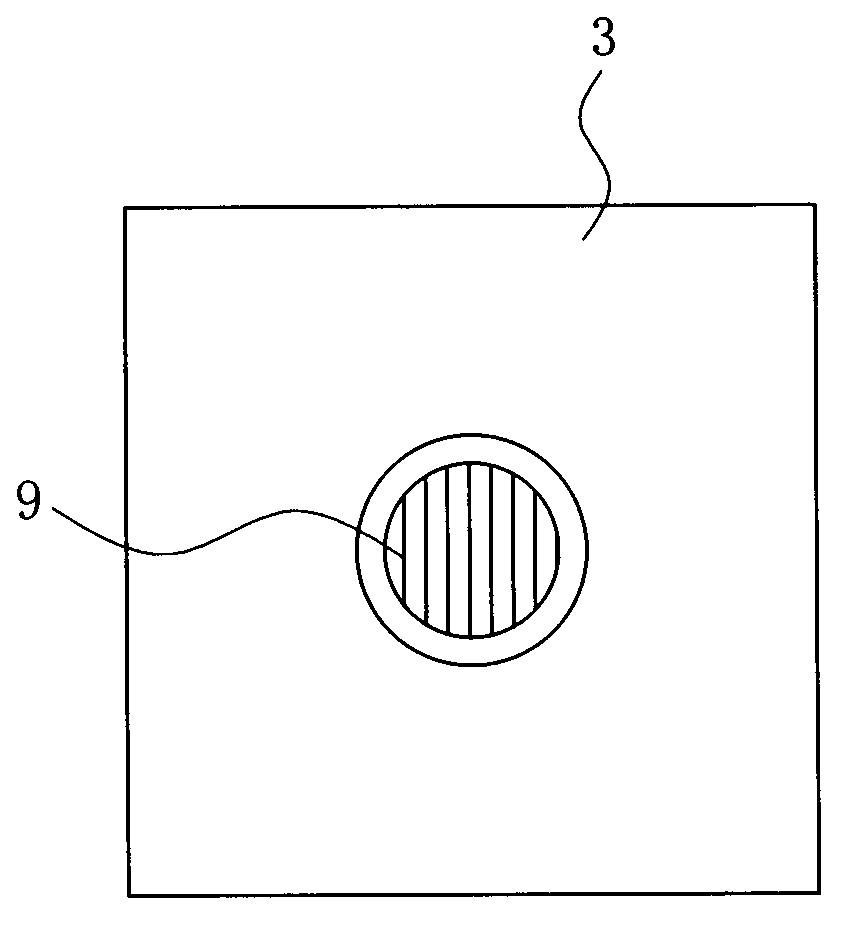

[0039] In this embodiment, the face plate 3 is a floor tile, 30cm×30cm, such as Image 6 , 7 As shown, the grid overhead layer 2 is clamped in the concave base 4, the grid overhead layer 2 is a PVC integrally formed structure, and the ...

Embodiment 2

[0042] Embodiment 2: An invisible floor drain, the structure of which is basically similar to that of Embodiment 1, the difference is that the base is a ceramic integrally formed structure.

Embodiment 3

[0043] Embodiment 3: An invisible floor drain, the structure of which is basically similar to Embodiment 1, the difference is that: the base is made of stamped and bent metal plates; the grid overhead layer is composed of a metal grid layer and a 7×8 =56 metal pillars are welded and fixed, and one metal pillar is arranged at each intersection point of the metal grid layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com