Exhaust silencer modular design method

A modular design, exhaust muffler technology, applied in exhaust devices, mufflers, mechanical equipment, etc., can solve the problem of low generalization of exhaust mufflers, improve the level of modularization and generalization, and shorten production. cycle, the effect of meeting the requirements of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

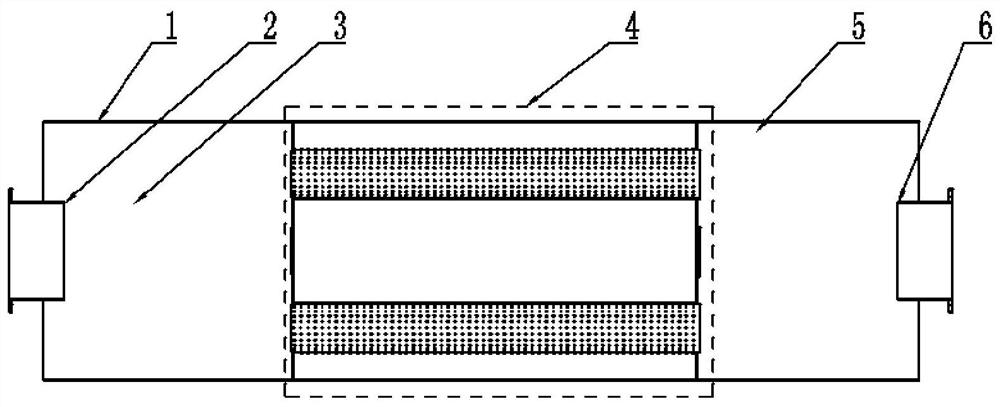

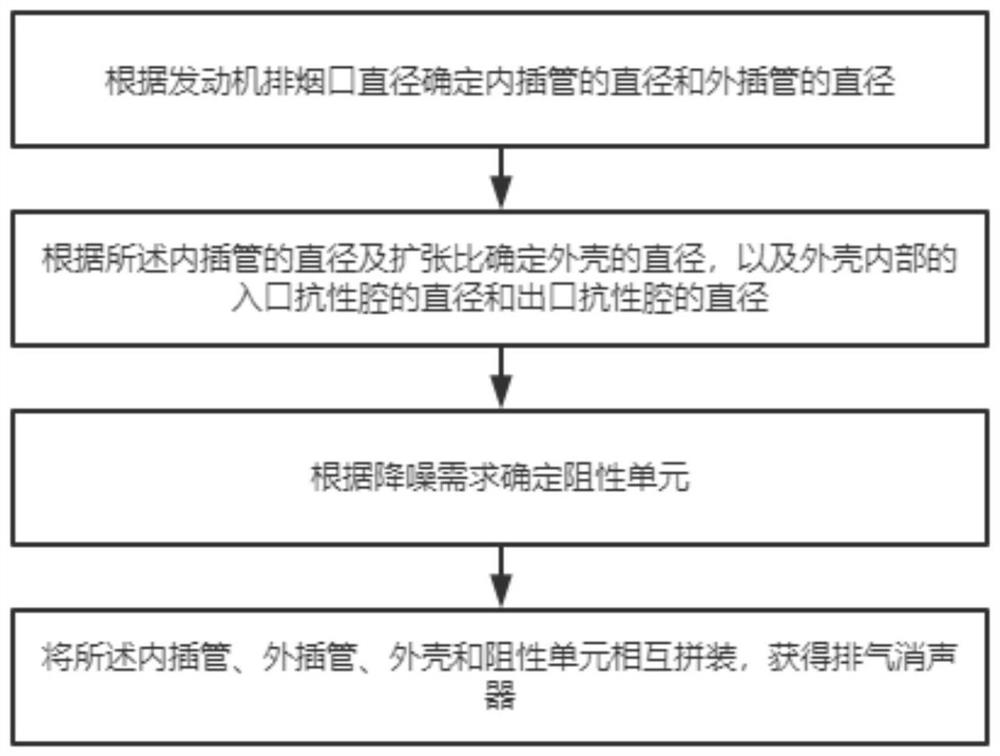

[0084] The modular design method of the exhaust muffler includes the following steps:

[0085] S1. Determine the diameter of the inner tube and the diameter of the outer tube according to the diameter of the engine exhaust port;

[0086] S2. Determine the diameter of the outer shell according to the diameter and expansion ratio of the inner cannula, and the diameter of the entrance resistance cavity and the diameter of the exit resistance cavity inside the shell;

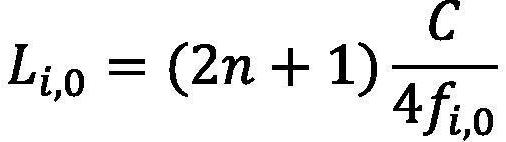

[0087] S3. Determine the resistive unit according to the noise reduction requirement;

[0088] S4. Assembling the inner tube, the outer tube, the shell and the resistive unit together to obtain an exhaust muffler.

[0089] For example, the diameter of the exhaust port of a certain engine is 71mm, the peak frequency of exhaust noise is 800Hz, and the sub-peak frequency of exhaust noise is 1600Hz, and the noise reduction of the resistive unit is required to be 15dB. Assume that according to the cluster analysis result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com