Scroll compressor and oil-gas separation device thereof

A scroll compressor and separation device technology, which is used in rotary piston machinery, rotary piston pumps, components of pumping devices for elastic fluids, etc. The effect of reducing the failure rate and manufacturing cost of the whole machine, reducing the noise and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

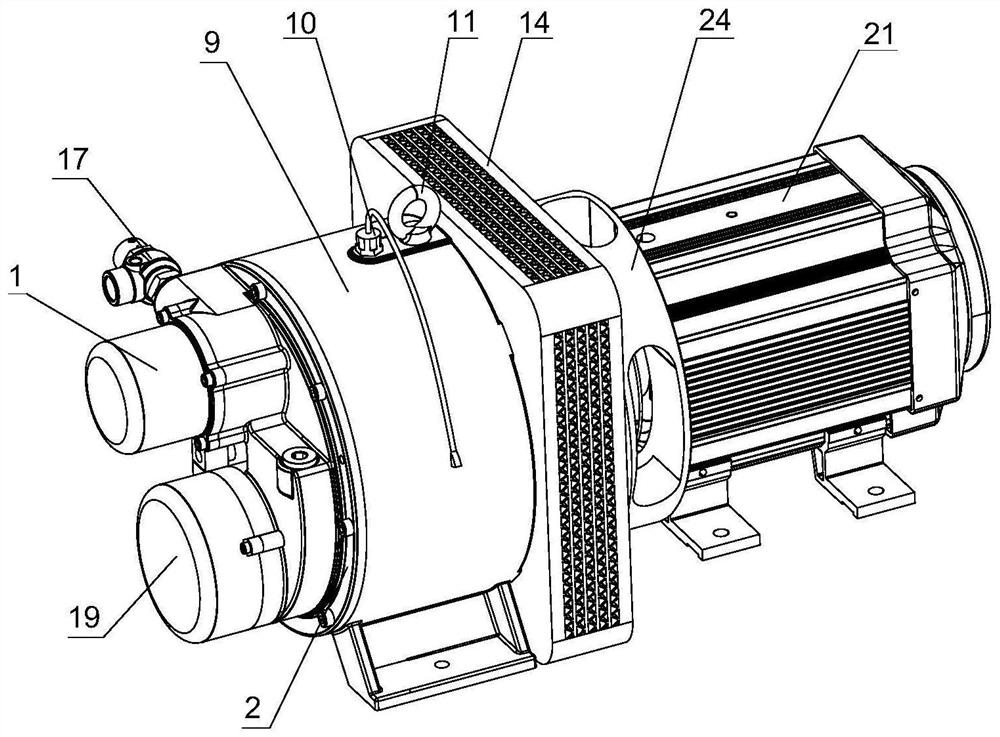

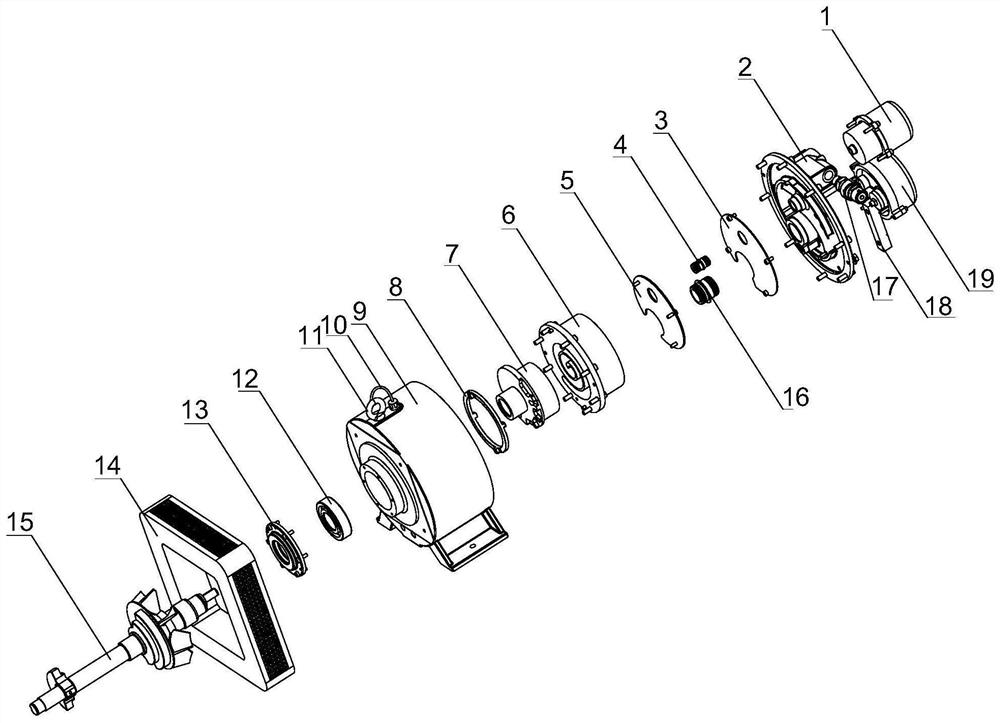

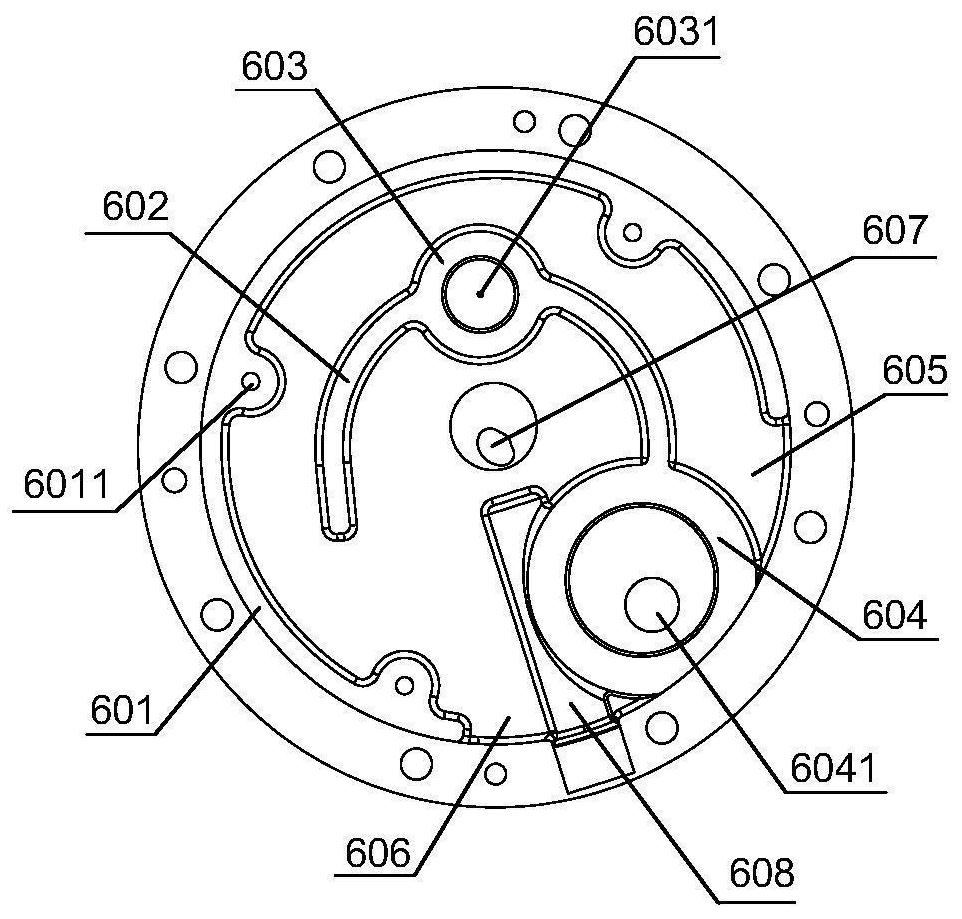

[0039] Such as Figures 1 to 6As shown, a crude oil and gas separation device for a scroll compressor includes a coarse separation cover plate 5 , a static disc 6 , a moving disc 7 and a fuselage 9 . Coarse separation cover plate 5 , static disk 6 and moving disk 7 are all located in the fuselage 9 . The bottom in the fuselage 9 is provided with an oil sump. The static disc 6 is fixedly arranged on the fuselage 9 . The moving disk 7 is cooperatingly arranged on the scroll portion on one side of the static disk 6 , and a compression chamber is formed between the moving disk 7 and the static disk 6 . An annular outer ring 601 , a first air guiding rib 602 , an oil return seat 603 and an air intake seat 604 are arranged on the other end surface of the static disk 6 . The annular outer ring 601 is arranged along the outer edge of the static disc 6 , and the rough separation cover plate installation hole 6011 is arranged on the annular outer ring 601 , and the coarse separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com