Crisscross steel structural member spacing measuring equipment

A steel structure and criss-cross technology, which is applied in the field of cross-type steel structure spacing measurement equipment, can solve the problems of easy-to-wear measuring ends, contact of impurity particles, measurement errors, etc., to ensure accuracy, ensure stability, and avoid friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

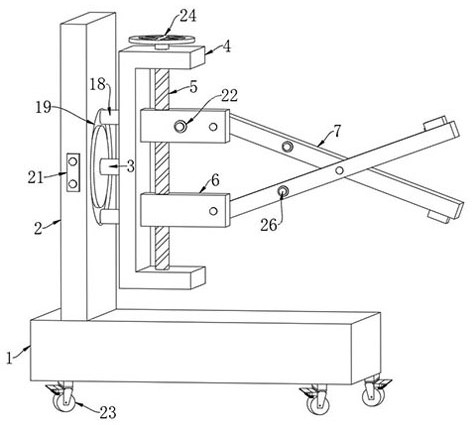

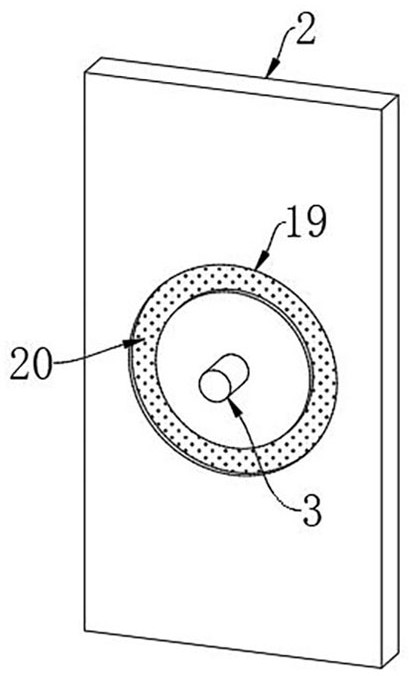

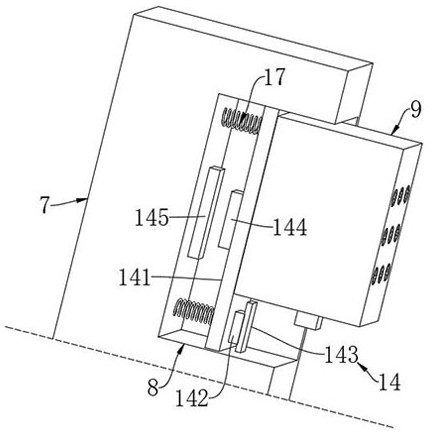

[0028] Such as Figure 1-5 As shown, a cross-type steel structure spacing measuring equipment includes a support base 1, a support plate 2 is fixedly connected to the support base 1, and a support shaft 3 is rotatably connected to the support plate 2, and the support shaft 3 is far away from the support plate 2. A frame 4 is fixedly connected to one end of the frame 4, and two metal blocks 18 are fixedly connected to the frame 4, and an annular chute 19 matching the two metal blocks 18 is provided on the support plate 2, and an electromagnetic chute 19 is embedded in the annular chute 19. strip 20, and the electromagnetic strip 20 is in contact with the metal block 18, and the support plate 2 is provided with a relay 21 electrically connected to the electromagnetic strip 20. Through the electromagnetic strip 20 provided, the magnetic change of the electr...

Embodiment 2

[0041] for Image 6 The second embodiment shown is different from the first embodiment in that a slider 27 is slidably connected to the protective groove 15, and the laser rangefinder 16 is arranged on the slider 27, and one side wall of the protective groove 15 is rotatably connected with a Nut cover 28, and screw rod 29 is threadedly connected in the nut cover 28, and one end of screw rod 29 extends to be set in the guard groove 15 and is fixedly connected with slide block 27, cooperates by the provided nut cover 28 and screw rod 29, makes later stage, can By turning the nut sleeve 28, the screw rod 29 pushes the laser rangefinder 16 to slide out of the protection groove 15, so that the user can disassemble and replace it conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com