Monte Carlo-based straightness measurement method under minimum entity requirement

A technology of straightness and straightness error, which is applied in the fields of precision measurement and computer application, and achieves the effect of stable method, easy popularization and fast calculation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

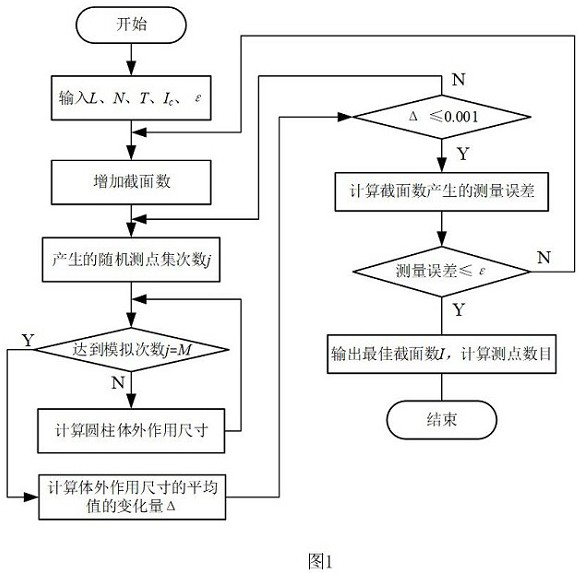

Method used

Image

Examples

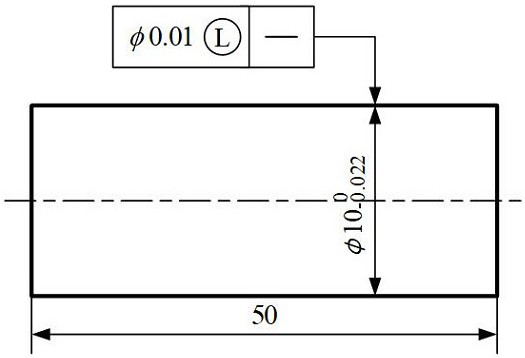

Embodiment Construction

[0033] The following are specific examples of the present invention, which are further described with the scheme of the present invention, but the present invention is not limited to these examples.

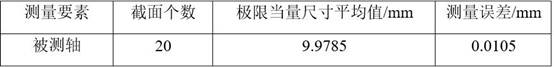

[0034] Step 1: According to this specific cutting method, the part material is 45 steel, the length L is 57mm, and the tool material is YT15. The dimensional error of the part during turning is predicted, and the calculation is obtained u mx =0.0011mm, u my =0.3288mm, u wx =0.00037mm, u wy =0.1284mm, d p =0.1 mm, put it into the formula to get a typical machining error model is banana shape, the relationship between the part length of a certain busbar and the dimensional error, the maximum dimensional error is 0.0618mm, which meets the dimensional tolerance requirements, and some data are shown in the table below ;

[0035]

[0036] Go to step 2 after step 1 is completed.

[0037] Step 2: Detect the part assuming that the section has N =48 measuring points, the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com