Integrated circuit board surface dust-free heat dissipation cooling method

A circuit board, integrated technology, applied in the field of dust-free heat dissipation and cooling on the surface of the integrated circuit board, can solve the problems of difficulty in ensuring the safety of high-end equipment, short circuit damage to the circuit board, and affecting the service life of the circuit board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with specific embodiments.

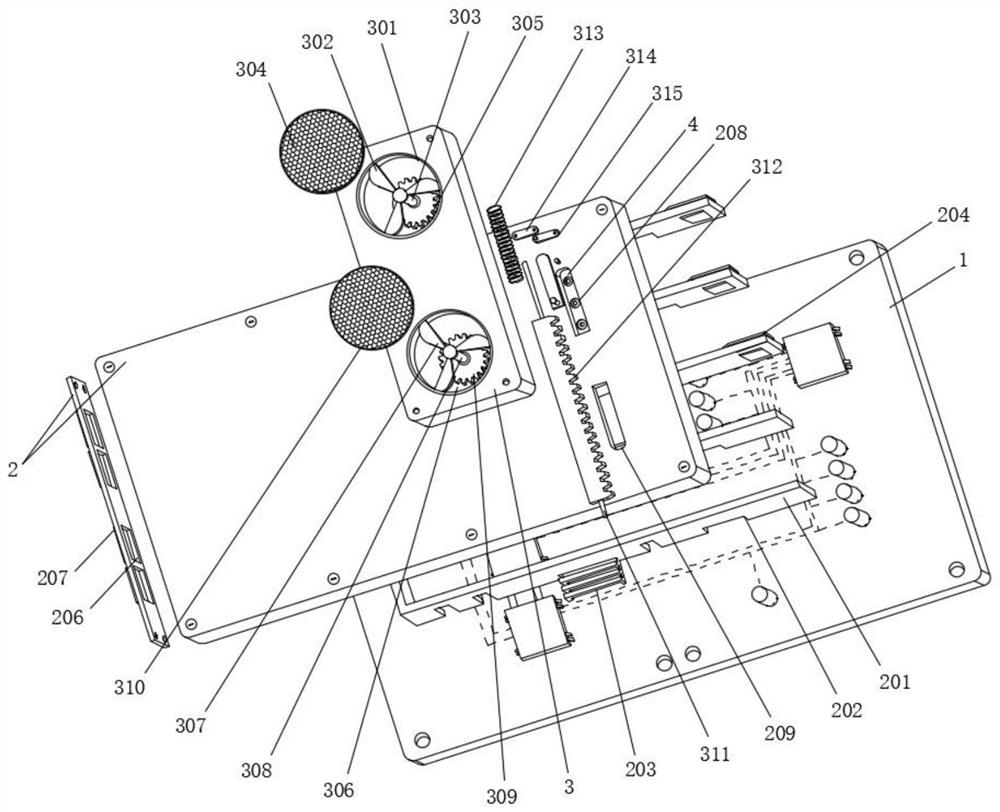

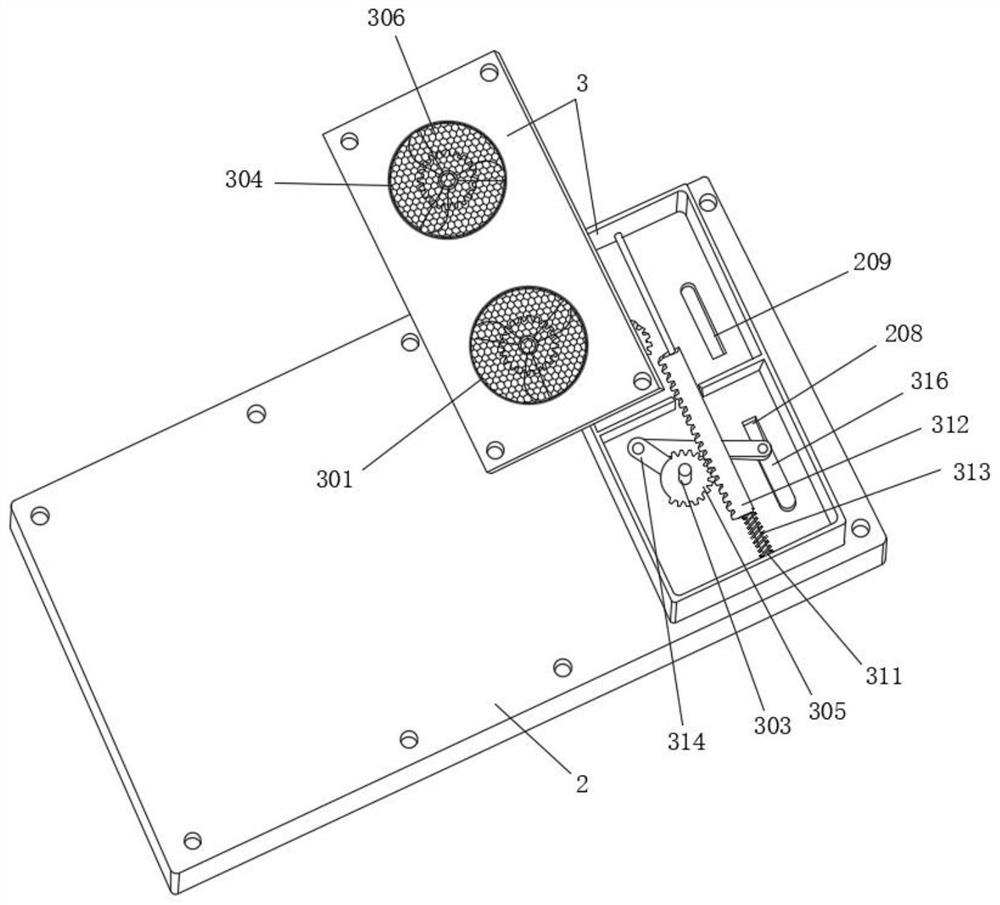

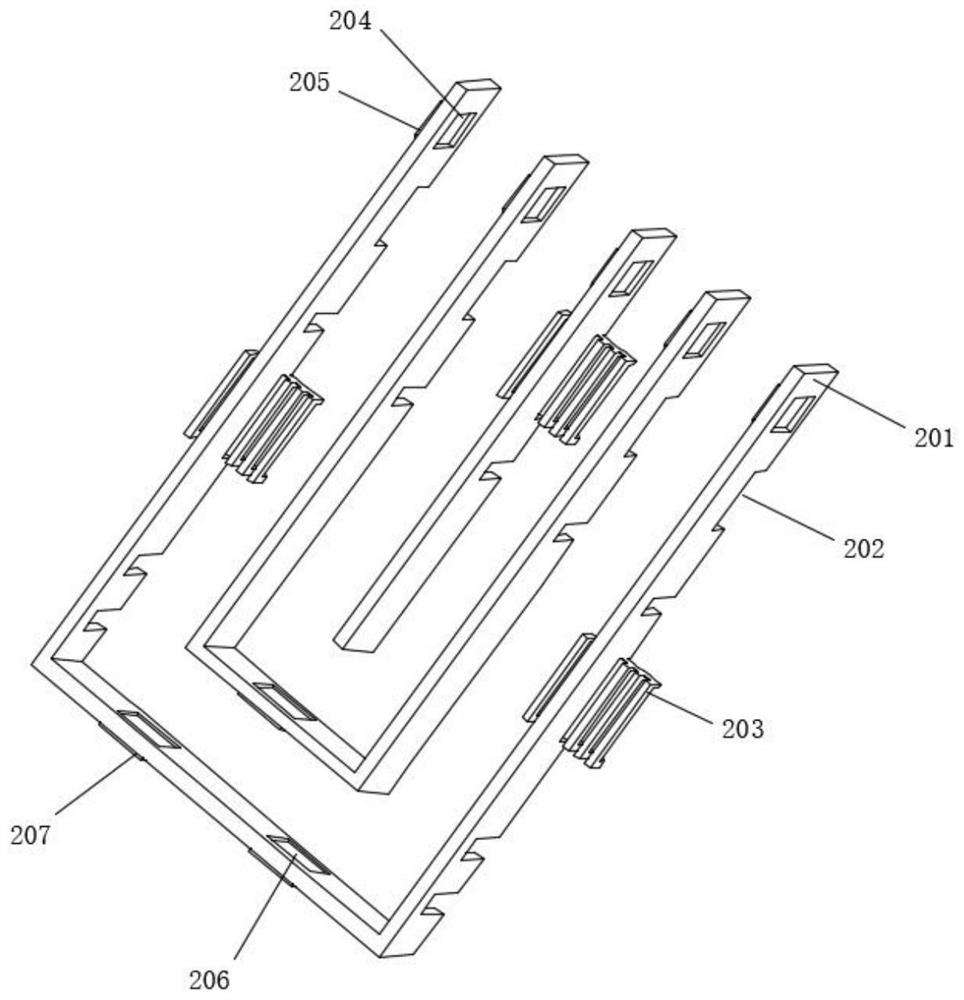

[0039] like Figure 1 - Figure 8 As shown, the surface dust-dissipated heat cooling assembly of the integrated circuit board of the present invention includes a PCB plate 1, a heat sink 2, a bellows 3, and a regulator 4, and the PCB plate 1 is fixed to heat sink 2, heat sink 2 is fixed to the bellows 3 as a structure, and there is a regulator 4 in the bellows 3, and the heat sink 201 is fixedly connected to the heat sink 201, and the heat dissipation plate 201 is provided with a fitting groove 202 and a heat shield 203, heat dissipation plate. The front end of 201 is provided with one pressure bleeding hole 204, and the one-stop pressure hole 204 is fixedly coupled with one shrapnel 205. On one side of the central and cooling box 2 of the heat dissipation plate 201, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com