Ozone producing system

a production system and ozone technology, applied in the field of ozone production system, can solve the problems of inadequate temperature lowering inside the electrolytic cell, lowering the efficiency of ozone gas concentration or electric current, etc., and achieve the effects of suppressing the rise of temperature in the electrolytic cell, uniform temperature, and enhancing cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

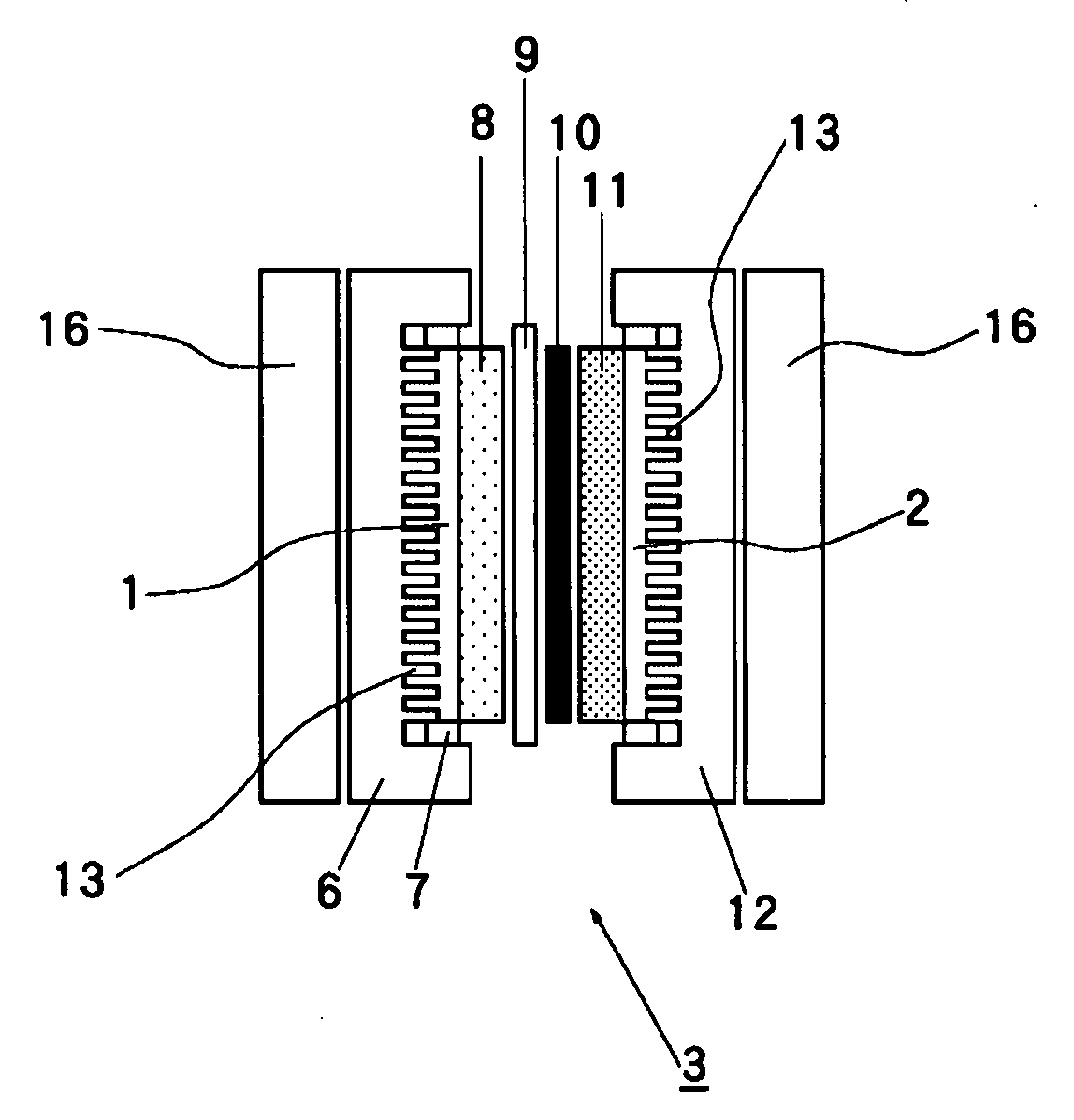

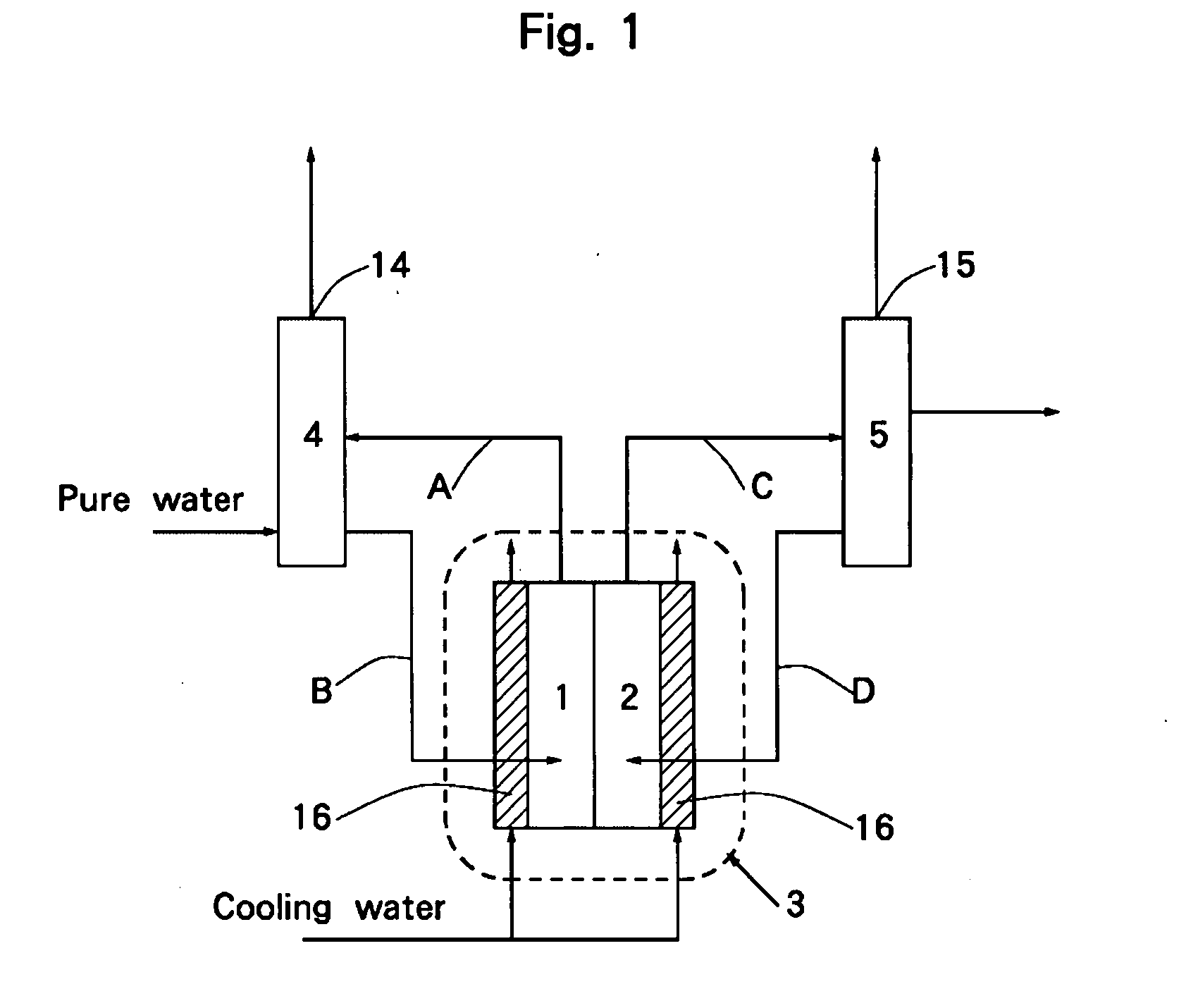

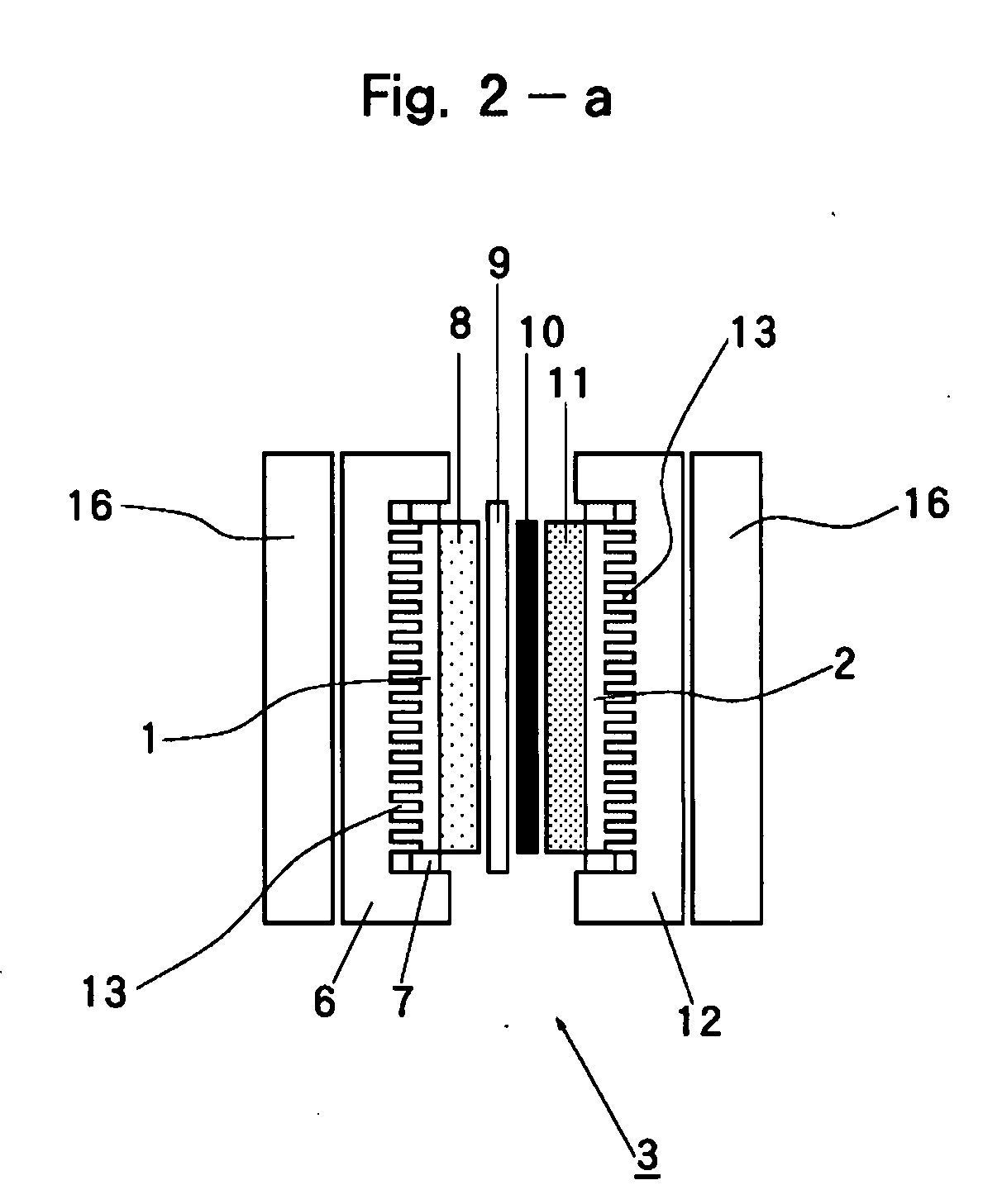

[0025]As an example of the present invention, electrolysis was conducted at a current density 200 A / dm2 using the ozone producing system shown in FIG. 1. In this experiment, the water electrolysis cell for ozone production, shown as 3 in FIG. 1 employed the cell shown in FIG. 2-a and FIG. 2-b. In FIG. 2-a and FIG. 2-b, 8 is the anode supported with ozone generation catalyst on the electrically conductive porous material, 9 is a perfluorocarbon sulfuric acid polymer ion exchange membrane, 10 is a cathode supported with platinum catalyst. Whereas, 6 is an anode compartment frame, and 12 is a cathode compartment frame, on which multiple numbers of grooves 13 as explained in FIG. 3 are formed. Anolyte and catholyte were circulated between the anode compartment 1 and the anolyte gas-liquid separation tower 4, and the cathode compartment 2 and the catholyte gas-liquid separation tower 5, respectively. The externals of the anode compartment frame 6 and the cathode compartment frame 12 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrolytic temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com