Linear cutting machine tool for automobile part production and using method thereof

A technology for wire cutting machine tools and auto parts, which is applied in electric processing equipment, electrode manufacturing, accessories and other directions, can solve the problems of time-consuming, high temperature safety hazards, and low safety of machine tools, so as to shorten adjustment time and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

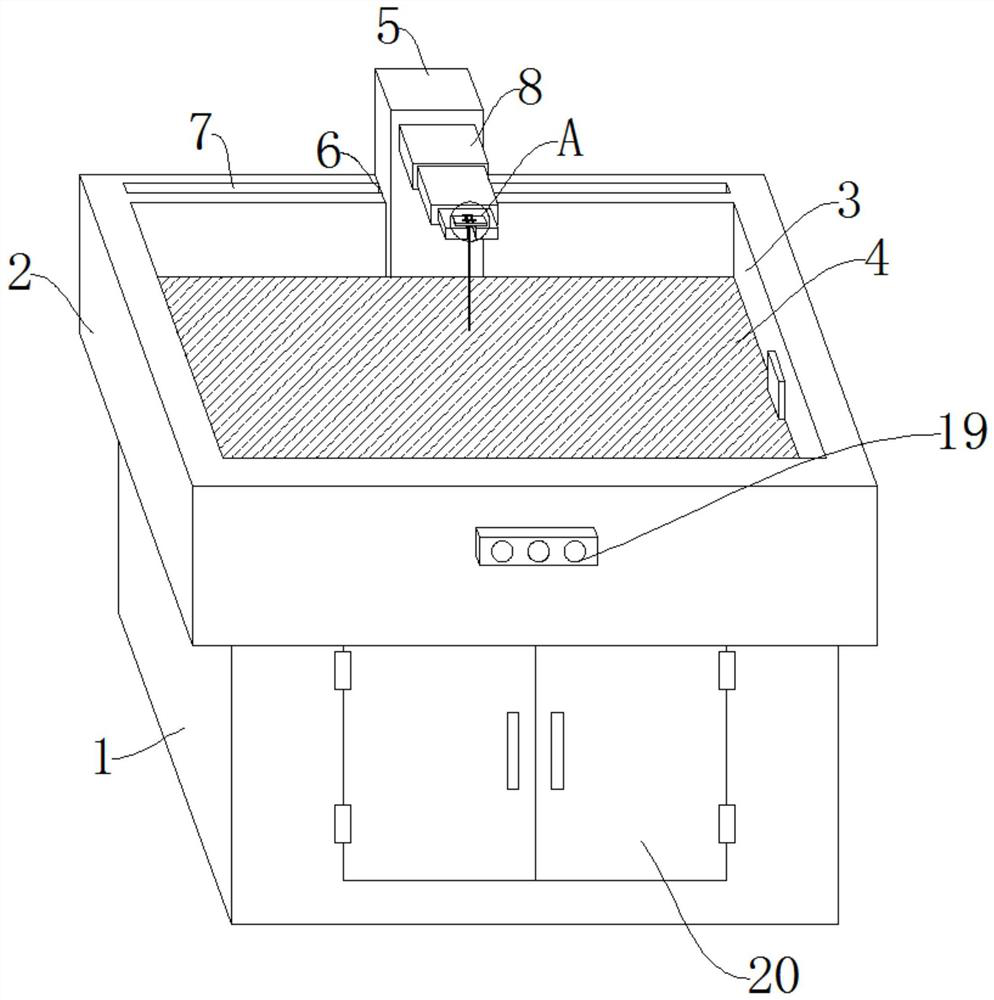

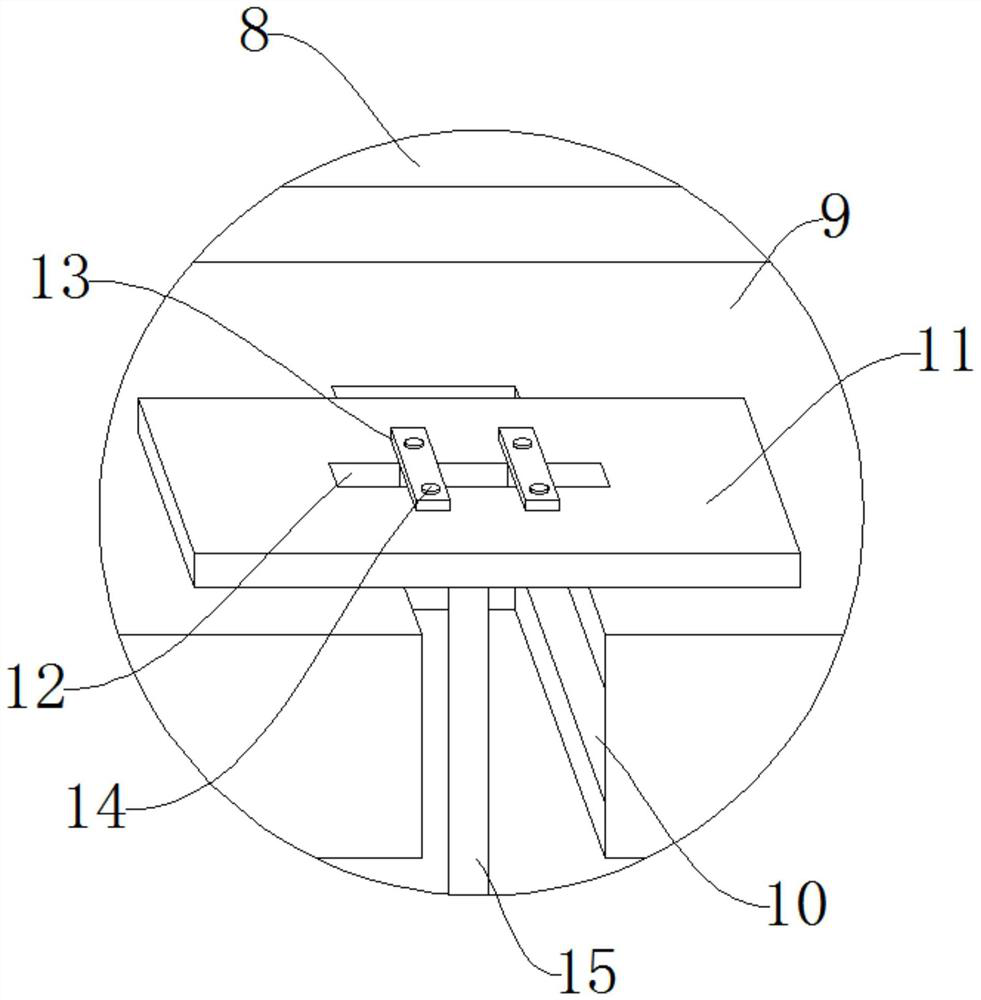

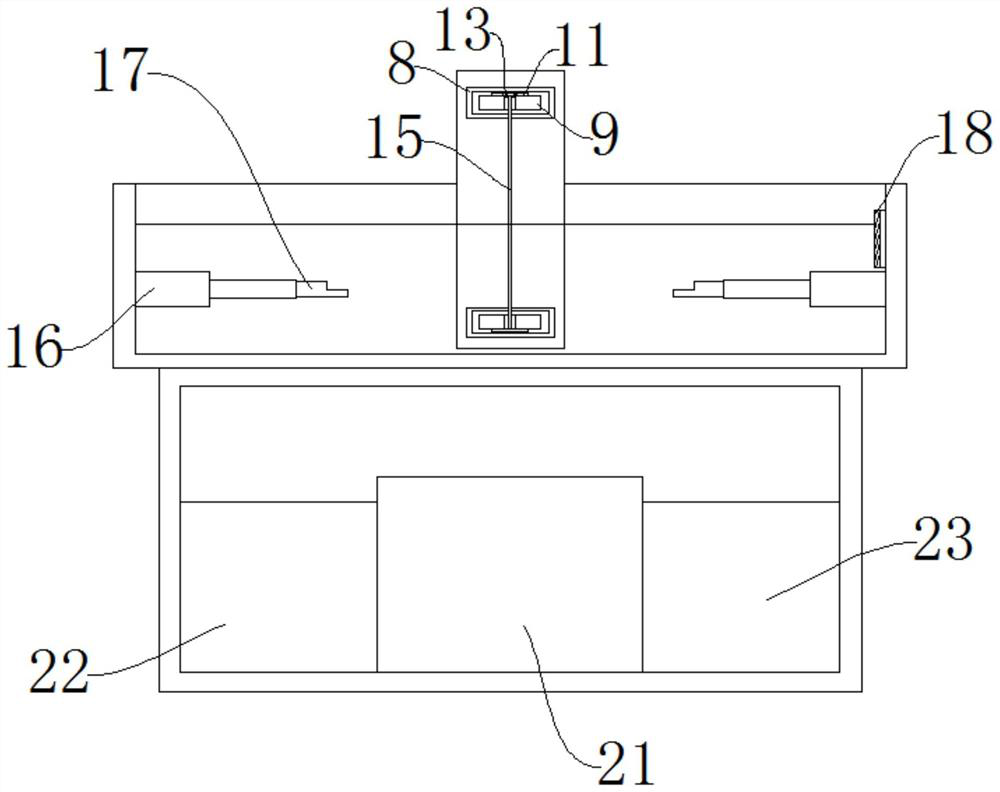

[0035] Such as Figure 1-Figure 4As shown, a wire cutting machine tool for the production of auto parts includes a machine base 1, a workbench 2 and a working tank 3, the workbench 2 is installed on the upper end of the machine base 1, and the upper end of the workbench 2 is formed with The working tank 3 is filled with an insulating cooling liquid 4, and the upper end of the workbench 2 is equipped with a mounting seat 5, and the lower end of the mounting seat 5 is formed with a slider 6. The workbench 2 The connection with the slider 6 is provided with an electric slide rail 7, and the upper and lower ends of the side wall of the mounting base 5 are equipped with an electric push rod 8, and an insulating clamp is installed at one end of the electric push rod 8 9. An accommodating groove 10 is formed on one side wall of the insulating fixture 9, a carrier plate 11 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com