Chip ball mounting method

A chip and ball planting technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as long working time and low success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The utility model will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0022] The invention provides a chip ball planting method, comprising the following steps:

[0023] S1: Use copper fiber heat conduction and organic flux to remove the original solder balls;

[0024] S2: The shape of the solder balls picked after reflow soldering may be different. To ensure the convenience of subsequent operations, remove all the solder balls on the substrate to restore the flatness of the substrate;

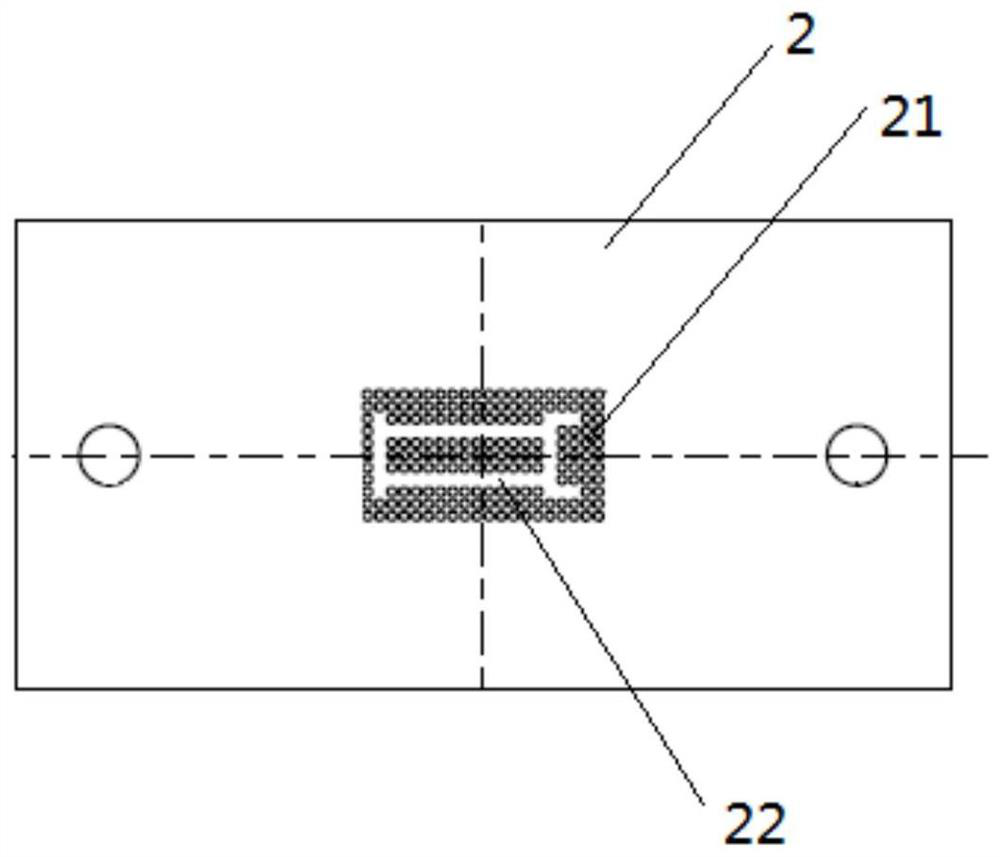

[0025] S3: Use jigs to distribute solder balls;

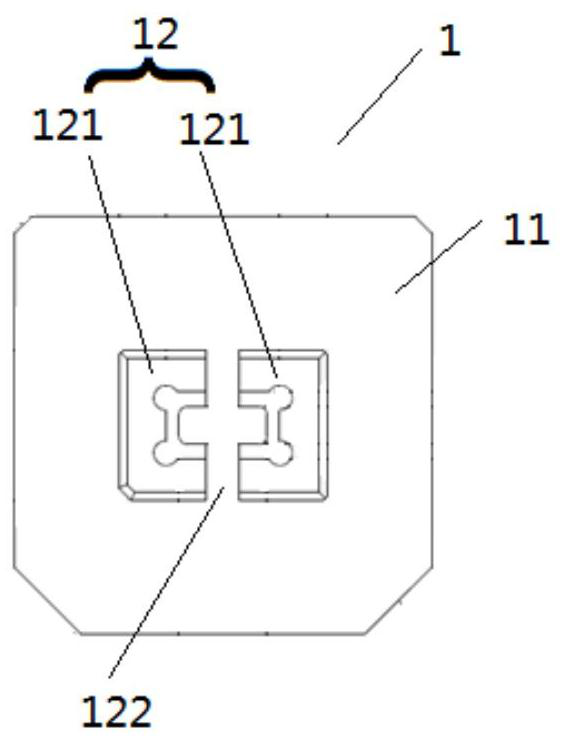

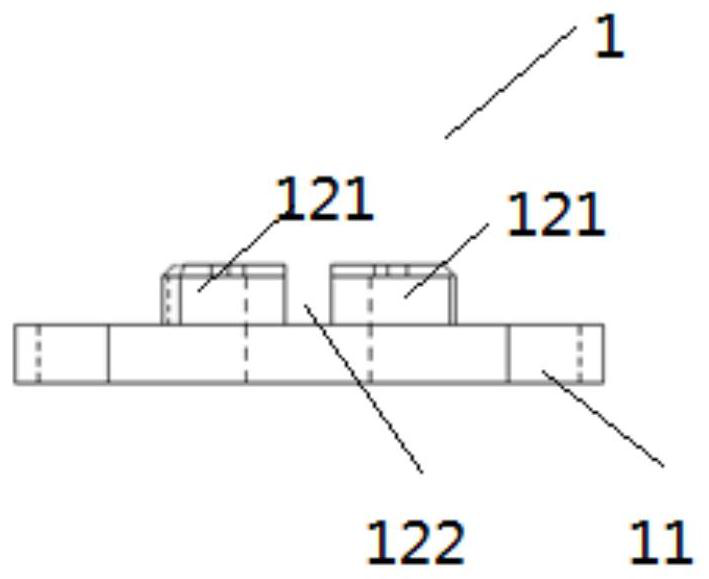

[0026] A planting device, comprising: a base 1 and a grid top plate 2;

[0027] The base 1 includes a bottom plate 11 and a placement platform 12, the placement platform 12 is arranged on the bottom plate 11; the placement platform 12 includes a protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com