Pigment impurity removal device for recovering polypropylene fibers and use method of pigment impurity removal device

A technology for recycling polypropylene and fibers, which is applied in recycling technology, plastic recycling, grain processing, etc., can solve problems such as uneven heating, high temperature, uneven temperature distribution, etc., achieve easy heating and melting, improve work efficiency, The effect of easy stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

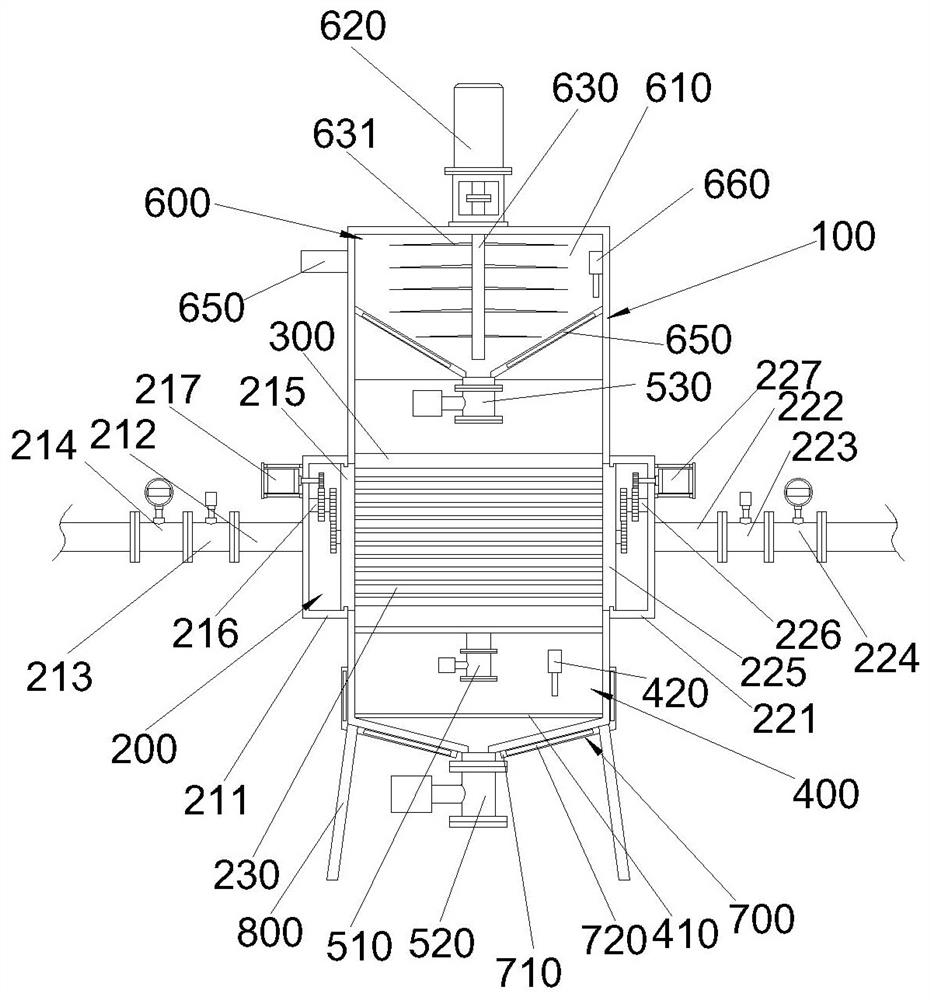

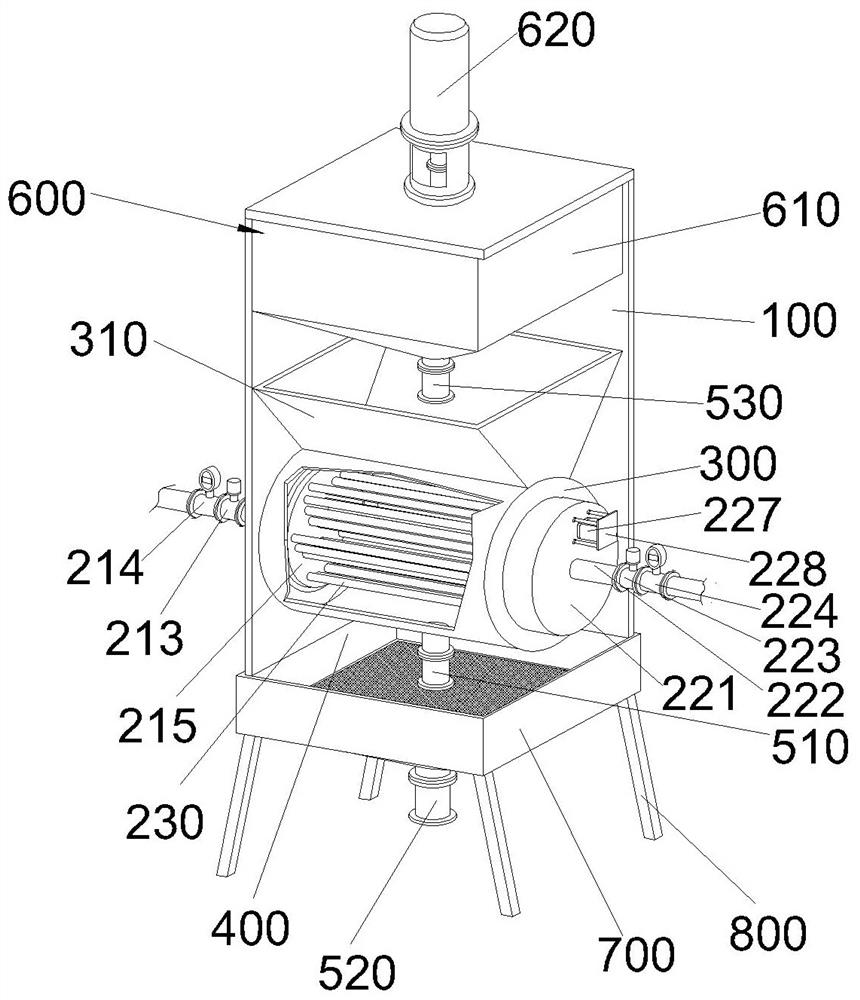

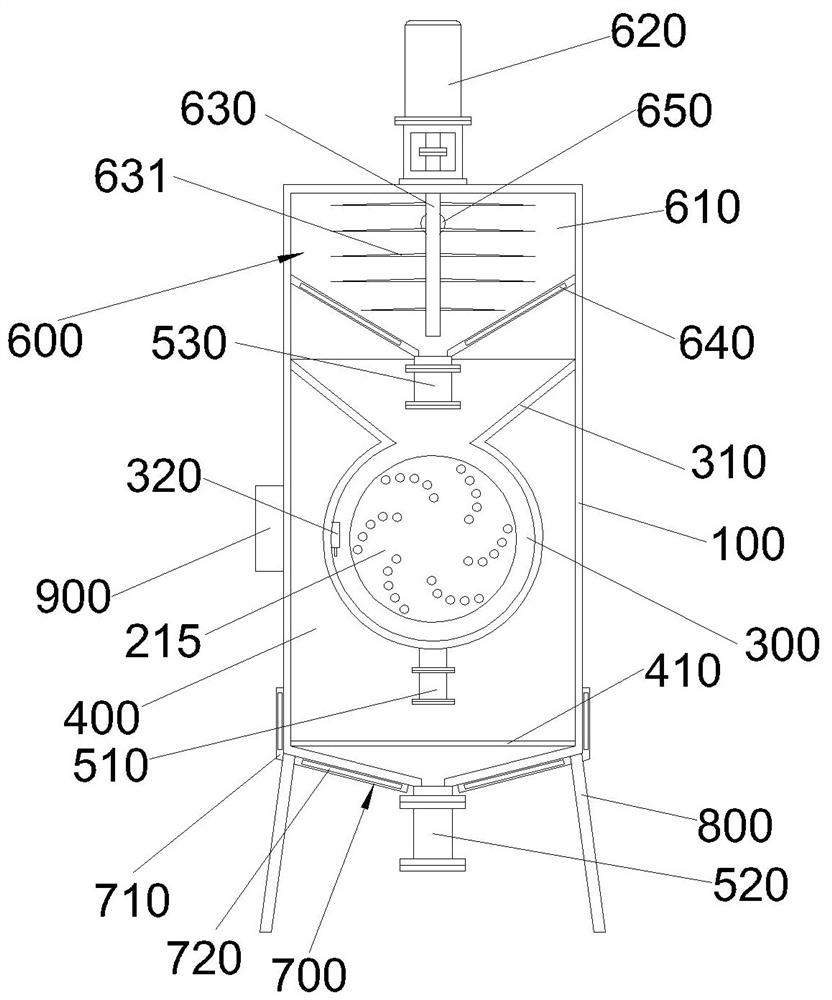

[0028] see Figure 1-Figure 5 , the present invention provides the following technical solutions: a pigment removal device for recycling polypropylene fibers and its use method, including a reaction kettle 100, the left and right side walls of the reaction kettle 100 are penetrated and equipped with a heating and stirring device 200, the The inside of the reaction kettle 100 is provided with a molten pool 300 and a sedimentation filter bin 400, the bottom of the molten pool 300 is provided with a discharge port and is fixedly connected with the first electronically controlled valve 510, and the bottom of the sedimentation filter bin 400 is provided with a discharge port And it is fixedly connected with the second electric control valve 520. The upper part of the inner cavity of the reaction kettle 100 is provided with a preheating crushing device 600, and the outer wall of the bottom of the reaction kettle 100 is covered with an anti-freezing heating device 700. The reaction A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com