Preparation method of lithium ion battery negative electrode and related device

A lithium-ion battery, negative electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, negative electrodes, etc., can solve the problems of many copper foils and separators, low charging and discharging efficiency, and small reaction area, etc., to improve the heat dissipation effect, Improve energy density and ensure the effect of transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

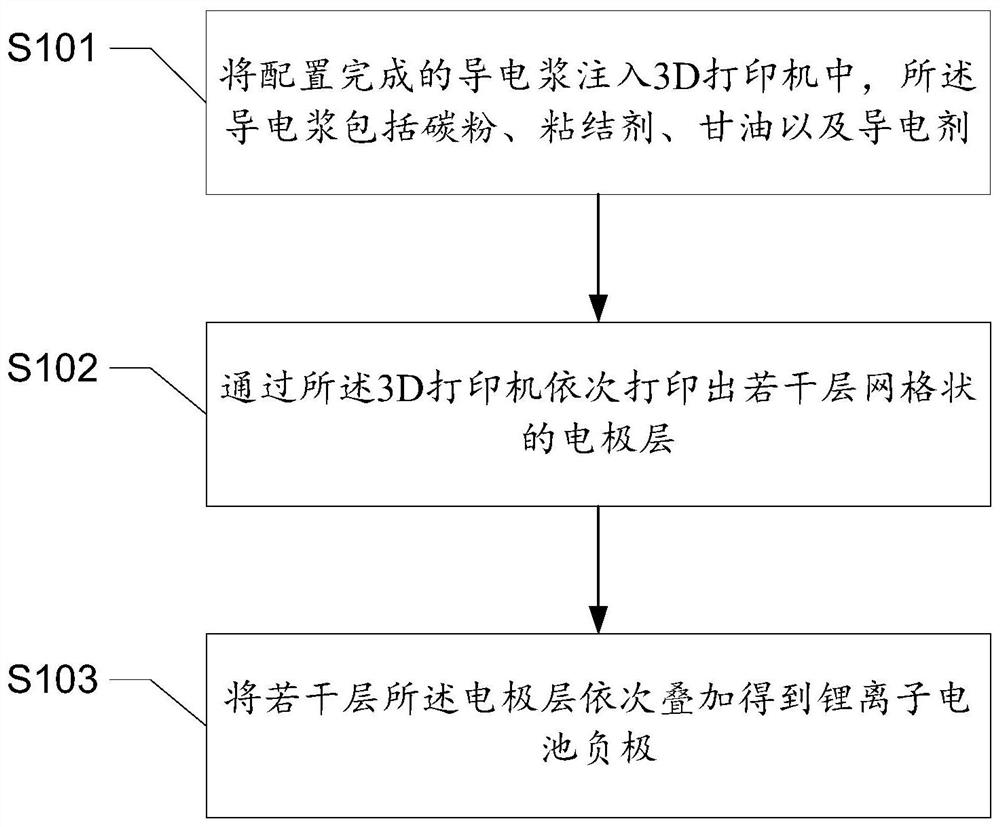

[0025] The embodiment of the present invention provides a kind of preparation method of lithium-ion battery negative electrode, as attached figure 1 shown, including steps:

[0026] S101. Inject the configured conductive paste into a 3D printer, where the conductive paste includes carbon powder, a binder, glycerin and a conductive agent.

[0027] Specifically, the 3D printer is an existing device and will not be further described here.

[0028] Specifically, the composition percentage of the conductive paste is: the carbon powder (graphite powder) 70% to 85%, the binder 5% to 10%, the glycerin 5% to 10%, the conductive agent 5% to 10%. Of course, according to actual needs, the conductive paste can also be properly adjusted, and the components of the conductive paste can be added with other components, or the existing conductive paste formula can be used.

[0029] S102, sequentially printing several grid-shaped electrode layers by the 3D printer.

[0030] Specifically, the ...

Embodiment 2

[0042] The embodiment of the present invention provides a lithium ion battery negative electrode, such as the attached figure 1 As shown, the negative electrode of the lithium ion battery is prepared by the preparation method of the negative electrode of the lithium ion battery described in Example 1.

[0043] Compared with the prior art, the lithium-ion battery negative electrode in this example is prepared by the preparation method of the lithium-ion battery negative electrode described in Example 1, so that the porous structure of the electrode layer can buffer its inner cavity for long-term charging and discharging. The volume expansion caused by the heat generated in the cycle, and the heat generated by charging and discharging can be quickly transferred to the battery shell with the porous structure to improve the heat dissipation effect, which is beneficial to the safety performance of the battery, and can also make it have too much The area reacts with the electrolyte ...

Embodiment 3

[0045] The embodiment of the present invention provides a lithium ion battery, such as the attached figure 1 As shown, the lithium ion battery negative electrode described in the second embodiment is included.

[0046]Compared with the prior art, the lithium-ion battery in this embodiment uses the negative electrode of the lithium-ion battery in Embodiment 2, so that the porous structure of the electrode layer can buffer the heat generated by the inner cavity during the long-term charge-discharge cycle. The resulting volume expansion, and the heat generated by charging and discharging can be quickly transferred to the battery shell with the porous structure to improve the heat dissipation effect, which is beneficial to the safety performance of the battery, and can also make it have too much area to react with the electrolyte. Improve energy density and ensure a smooth transmission path for electrons to improve charge and discharge efficiency, and because no current collector ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com