A kind of processing device for producing propylene glycol and using method thereof

A processing device, propylene glycol technology, applied in separation methods, chemical instruments and methods, separation/purification of hydroxyl compounds, etc., can solve the problems of shortening the heating time of hydrogen and glycerin solutions, inability to integrate propylene glycol, and high water content of propylene glycol. Achieve the effects of improving synthesis efficiency, improving purification efficiency and purification effect, and improving purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

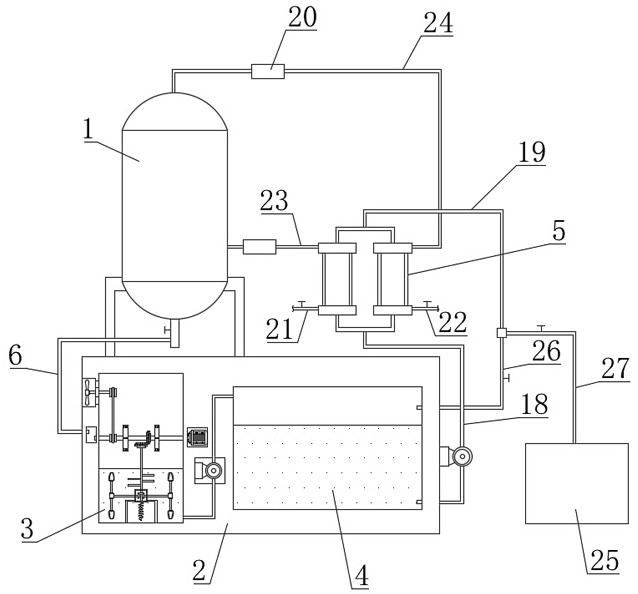

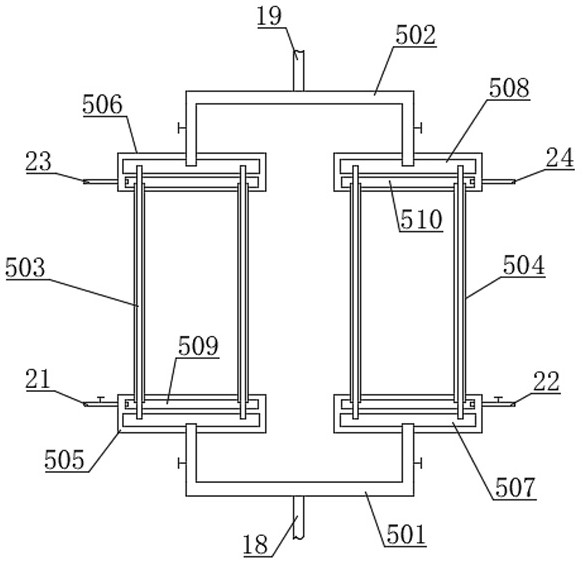

[0047] Such as Figure 1-5 As shown, a kind of processing device that the present invention proposes is used to produce propylene glycol, comprises synthesis reactor 1, purification storage tank 2, hydrogen input pipe 21, glycerol input pipe 22, hydrogen output pipe 23 and glycerol output pipe 24, synthesis reaction The still 1 is fixed on the top of the purification storage tank 2 through the installation frame, and the bottom of the synthesis reaction kettle 1 is provided with a discharge pipe with a valve, and a connecting pipe 6 is installed on the discharge pipe, and the other end of the connecting pipe 6 is connected to the purification storage tank. 2 connection, the synthesis reactor 1 is equipped with a pressure relief pipe communicating with it, and the pressure relief pipe is provided with a valve. When the pressure in the synthesis reaction kettle 1 is too high, the pressure relief pipe discharges the internal gas to play a protective role, purify and store An evap...

Embodiment 2

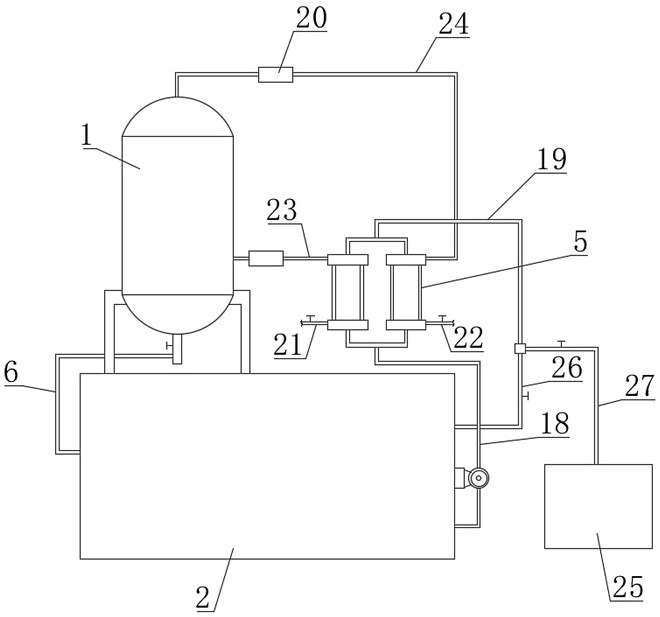

[0053] Such as figure 1 and figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the end of the infusion tube 19 away from the second U-shaped pipe 502 is equipped with a return tube 26 and a collection tube 27, and a temperature sensor is installed in the infusion tube 19, and the infusion is controlled by the temperature sensor. The temperature of the propylene glycol solution output in the pipe 19 is detected, and the other end of the return pipe 26 is communicated with the heat preservation storage chamber 4, and the other end of the collection pipe 27 is connected with the propylene glycol collection box 25, and the return pipe 26 and the collection pipe 27 are all provided with valves, When the temperature data of the liquid in the infusion tube 19 is less than a certain value, the valve on the collection pipe 27 is opened, and the propylene glycol solution flows back into the propylene glycol collection box 25 through the collection pipe 2...

Embodiment 3

[0055] Such as Figure 5 , Figure 6 and Figure 10 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that a liquid inlet chamber 9 is provided in the purification storage tank 2, and the connecting pipe 6 communicates with the liquid inlet chamber 9, and the connecting pipe 6 synthesizes in the synthesis reactor 1 The propylene glycol solution is transported into the liquid inlet chamber 9, and a drive motor 12 is fixedly installed on the purification storage box 2 through a motor base. A hollow rotating rod 10 is arranged horizontally in the evaporation purification chamber 3, and one end of the hollow rotating rod 10 extends into the liquid inlet chamber. In the cavity 9 and communicated with it, the other end of the hollow rotating rod 10 is connected to the output end of the driving motor 12, and the driving motor 12 is used to drive the hollow rotating rod 10;

[0056] The outer peripheral surface of the hollow rotating rod 10 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com