Control method of rubber tube vulcanization process

A control method and process technology, applied in the control field of the rubber hose vulcanization process, can solve the problems of low overall temperature in the vulcanization process, uneven product quality, and different vulcanization depths, etc., to shorten the heating time, improve repeatability, and reduce energy. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Control method for a hose vulcanization process, steps below:

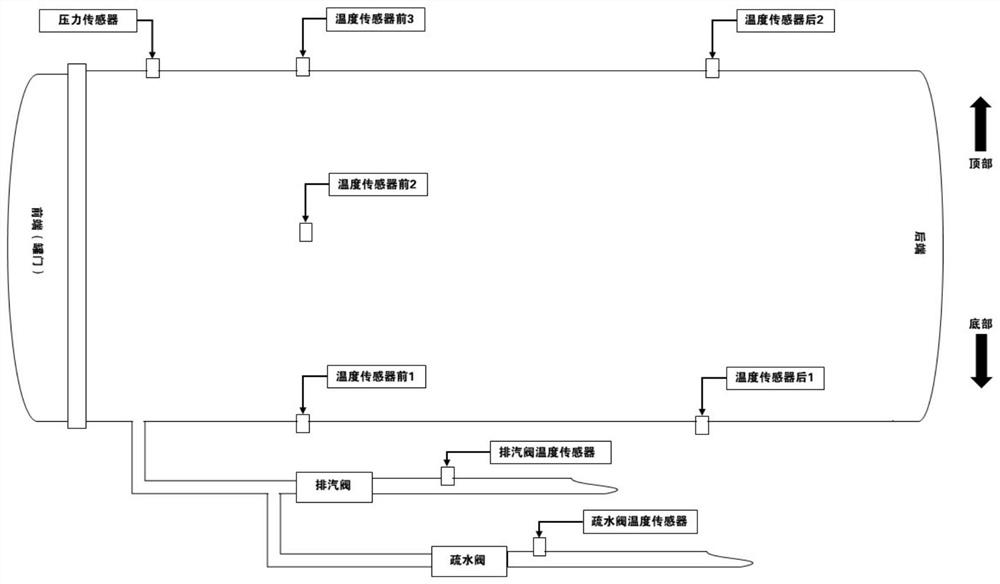

[0031] (1) Operation of temperature sensors and pressure sensors: use conventional horizontal vulcanizers, such as figure 1 As shown, the temperature sensor and pressure sensor is installed at the factory preset; where the temperature sensor is mounted on the front and rear sections of the top of the vulcanizil, the front section of the temperature sensor 3 and the temperature sensor 2), the sulfide canister (ie temperature " The sensor front 2), the front and rear sections of the vulcanized canister (i.e., the temperature sensor 1 and the temperature sensor 1), the rear end of the exhaust valve rear end and the roll valve, a total of 7 temperature points; the pressure sensor is mounted on top of the vulcanized can Front section;

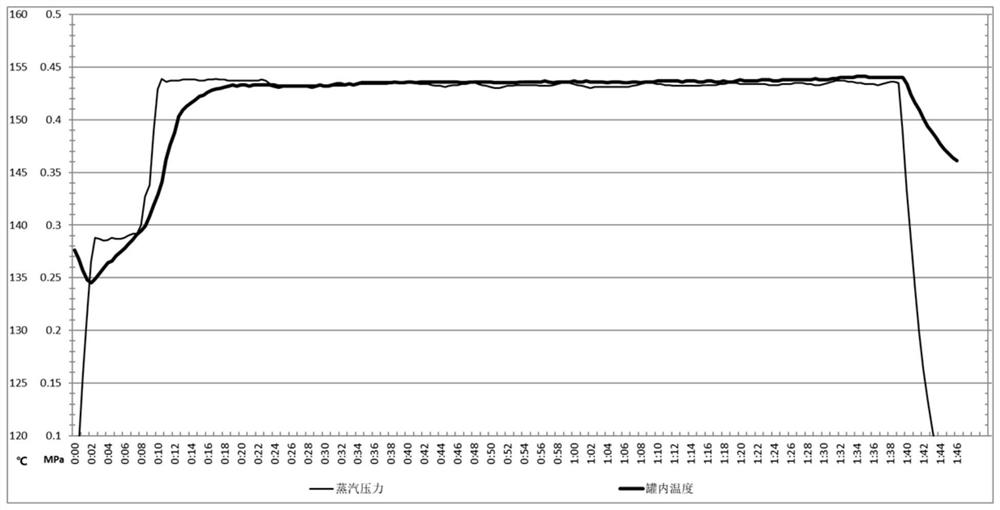

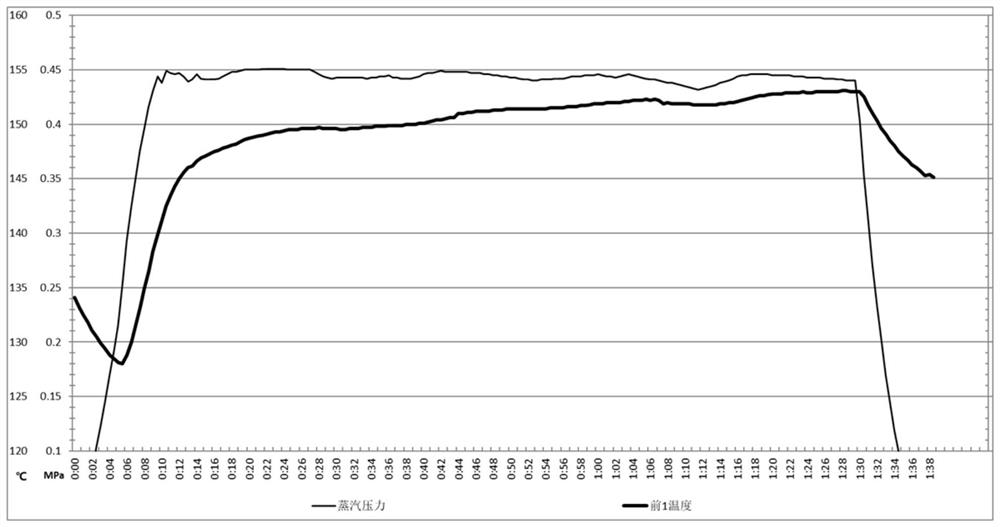

[0032] (2) Before the vulcanization, the temperature of the temperature sensor 1 to 3 and the temperature sensor 1 to 2 after the temperature sensor were confirmed that when the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com