Floating type liquid food material heating device

A heating device and material technology, which is applied in food science, food preparation, plant protein processing, etc., can solve the problems of uneven heating of materials, uneven heating of food materials, scaling of food materials on the wall, etc., and shorten the heating time , Improve temperature stability and heating uniformity, improve the effect of residence time accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

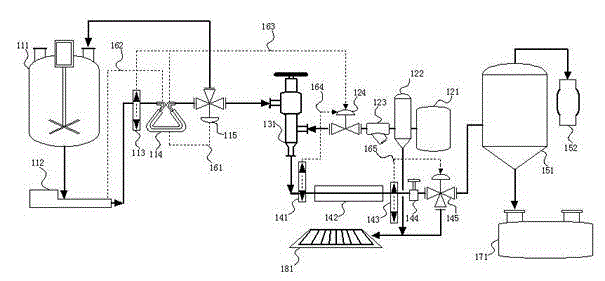

[0027] figure 1In the shown liquid suspension food material heating device, the liquid suspension food material is first injected into the material tank (111), and then the material is pressurized through the screw pump (112) to obtain a flow rate of 100 – 5000 L / h and 4 – 25 bar pressure, and through the thermal resistance (113) and mass flow meter (114), the temperature and mass flow information of the material is transmitted to the steam control valve (124) through the feedforward control loop (163) to adjust its opening, so that the steam Pass through the heater (131) in advance, and then the material also enters the heater (131) to mix and transfer heat with steam, so that the food material can obtain a heating temperature of 120-160 °C.

[0028] The thermal resistor (141) at the outlet of the heater (131) monitors whether the heated material reaches the target temperature, and adjusts the opening of the steam control valve to increase or decrease according to the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com