Stainless steel pipe welding device and welding method thereof

A stainless steel tube and welding device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of affecting welding quality, deteriorating welding seam quality and performance, laborious manual rotation, etc., to improve welding quality and flexible use. , The effect of easy spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

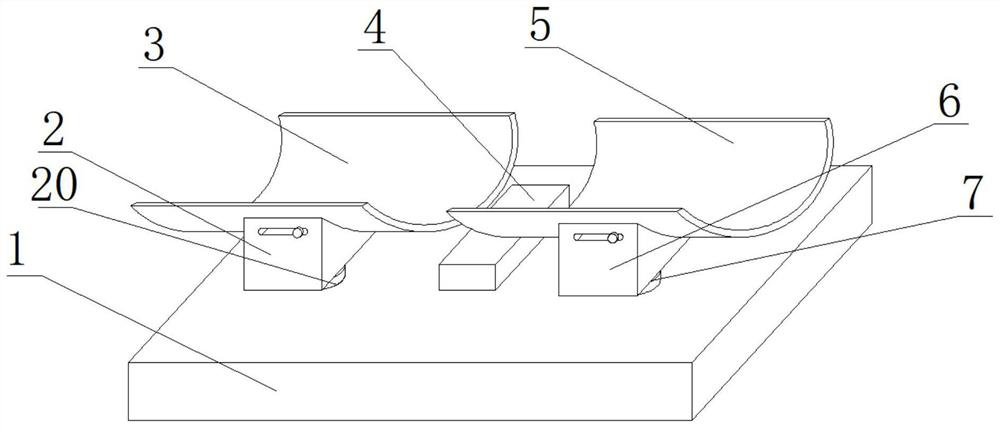

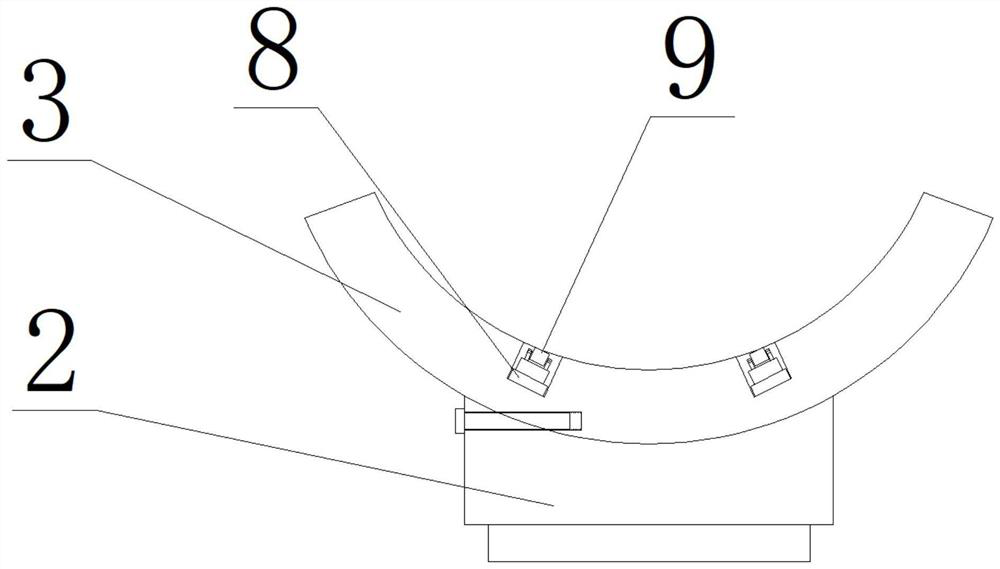

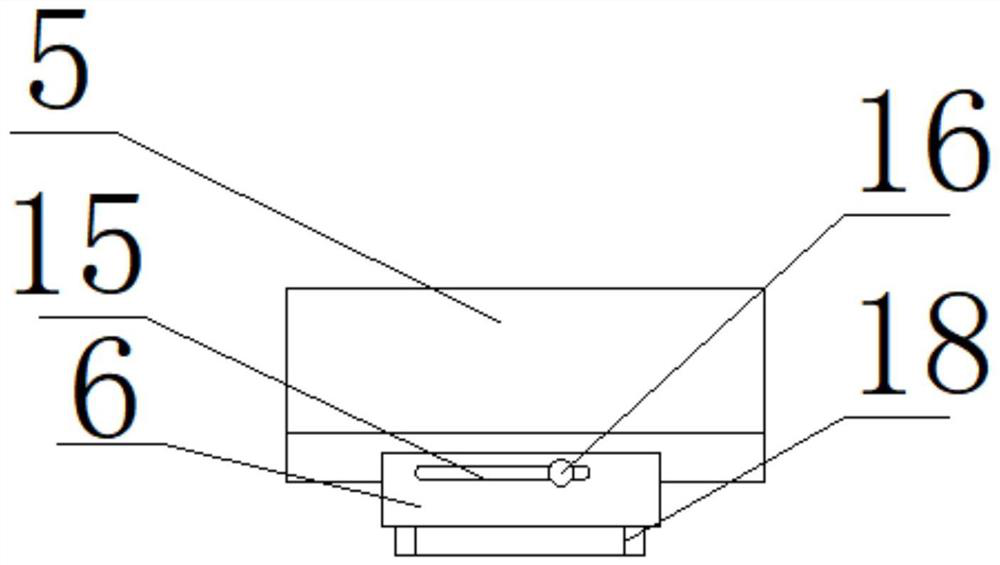

[0032] see Figure 1-5 , the present invention provides a technical solution: including a bottom plate 1, a left shell 2 and a right shell 6, a housing 4 is fixedly installed in the middle of the top surface of the bottom plate 1, a left ring 17 is fixedly installed on the left side of the top surface of the bottom plate 1, A right ring 7 is fixedly installed on the right side of the top surface of the bottom plate 1, a first arc plate 3 is placed on the top surface of the left shell 2, a second arc plate 5 is placed on the top surface of the right shell 6, and the first arc plate 5 is placed on the top surface of the right shell 6. There are cavities equally spaced on both sides of the bottom of the inner wall of the plate 3, an electric push rod 8 is installed on the bottom of the inner wall of the cavity, a roller 9 is installed on the top of the electric push rod 8, and a chute 15 is opened on the top of the outer wall of the right shell 6 , a sliding rod 16 is slidably in...

specific Embodiment 2

[0034]The present invention provides a technical solution: a stainless steel pipe welding device and its welding method, including a bottom plate 1, a left shell 2 and a right shell 6, a shell 4 is fixedly installed in the middle of the top surface of the bottom plate 1, and the top of the bottom plate 1 The left ring 17 is fixedly installed on the left side of the surface, the right ring 7 is fixedly installed on the right side of the top surface of the bottom plate 1, the first arc plate 3 is placed on the top surface of the left shell 2, and the first arc plate 3 is placed on the top surface of the right shell 6. The second arc plate 5, the two sides of the bottom of the inner wall of the first arc plate 3 are equidistantly provided with a cavity, the bottom of the inner wall of the cavity is equipped with an electric push rod 8, and the top of the electric push rod 8 is equipped with a roller 9. The top of the outer wall of the right shell 6 is provided with a chute 15, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com