Anti-crease non-winding type trimming machine

A coiling and shearing machine technology, which is applied in textiles and papermaking, knitting, warp knitting, etc., can solve the problems that the fabric cannot be cut neatly, the gray cloth or floating thread is not cut cleanly, and the tension of the shearing machine is not enough. Sustainable production, high practical value, and guaranteed tidy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

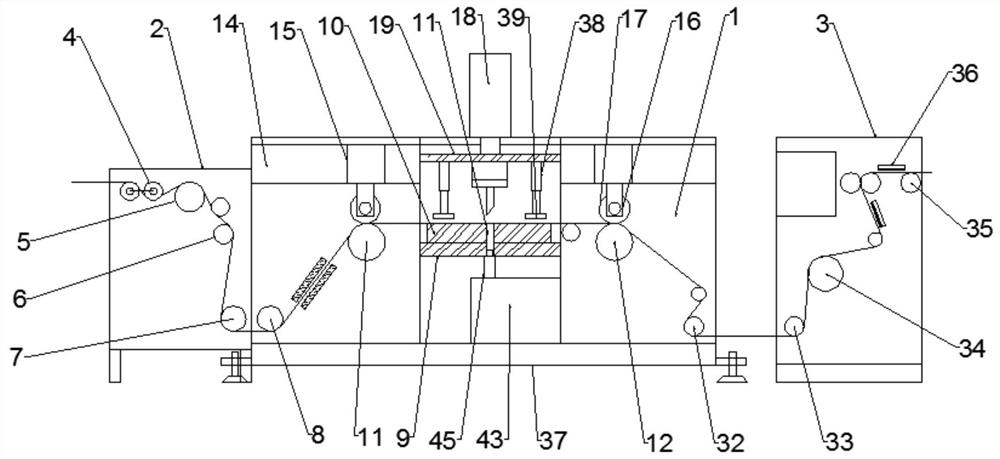

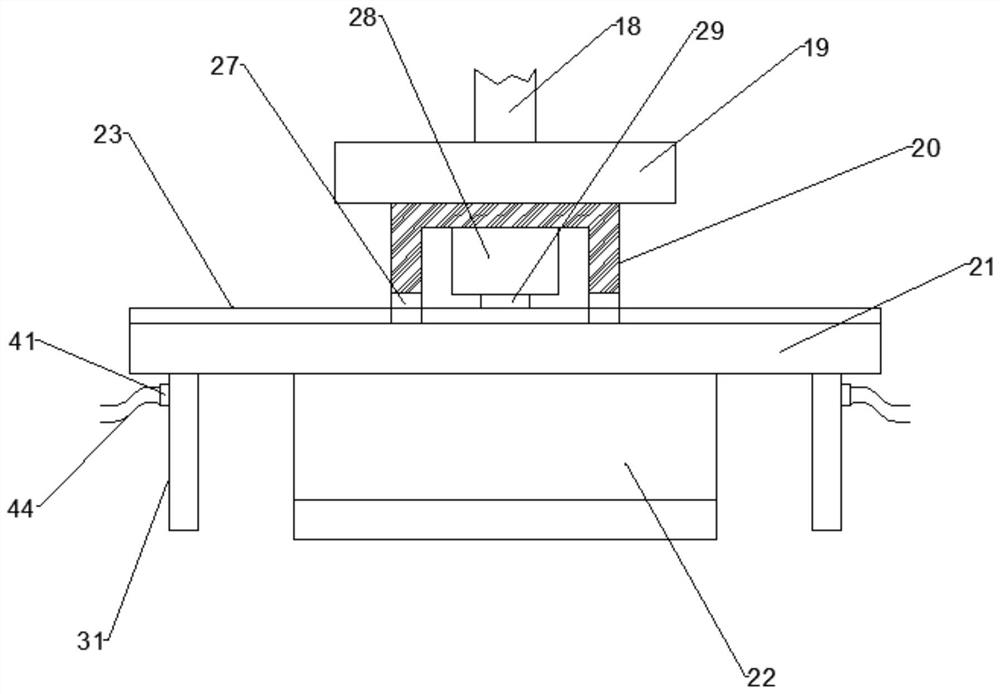

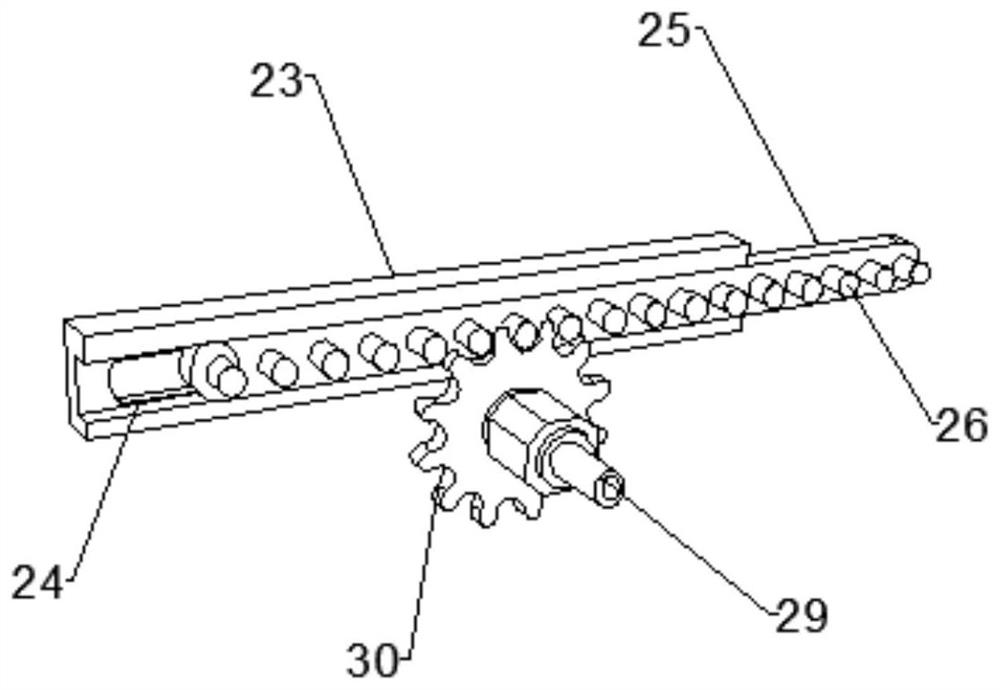

[0025] Such as Figure 1-4 As shown, the shearing machine according to the embodiment of the present invention includes a shearing box 1, an expanding box 2 and a connecting box 3, and the shearing box 1 is located between the expanding box 2 and the connecting box 3. The middle part of the connection box 3, the expansion box 2 and the connection box 3 are located at the two ends of the shear box 1, the inside of the expansion box 2 is provided with a tension angle roller 4, and the tension angle roller 4 One side of the expansion roller 5 is provided with a centering structure 6 at the lower end of the expansion roller 5, and a traction roller-7 is provided at the lower end of the centering structure 6, and the inner side of the shearing box 1 is provided with Traction roller 2 8 is arranged, and the interior middle part of described shearing box 1 is provided with fixed plate 9, and the upper end middle part of described fixed plate 9 is provided with shearing table 10, and ...

Embodiment 2

[0028] Such as Figure 1-4As shown, the lower ends of the shear box 1, the expansion box 2 and the connection box 3 are provided with a support plate 37, and the lower end of the shear box 1 and both sides of the support plate 37 are provided with The connecting bottom plate is provided with adjustable feet at both ends of the connecting bottom plate. The centering structure 6 is composed of two rudder rollers and a centering infrared sensor.

[0029] Such as Figure 1-4 As shown, sliders are provided on both sides of the lifting plate 19 , and slide grooves matching the sliders are provided on both sides of the shear box 1 located at the connecting frame 14 . The lower end of the lifting plate 19 and the both sides of the transverse blade 22 are provided with a spring telescopic rod 38, the lower end of the spring telescopic rod 38 is provided with a pressing plate 39, and the bottom end of the pressing plate 39 is provided with an anti-skid Rubber mat. Both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com