Spiral thread detection method and special instrument thereof

A detection method and helical pattern technology, which is applied in the direction of instruments, measuring devices, surveying and navigation, etc., can solve the problems of lack of good detection means and equipment, inability to directly distinguish with the naked eye, and low detection efficiency, and achieve simple structure and easy operation. Convenience and good detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

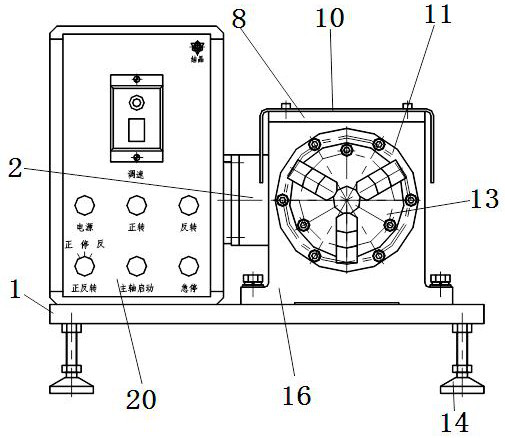

[0019] Such as Figure 1-Figure 3 As shown, a spiral pattern detector includes a base 1, and four adjustable feet 14 are installed on the lower end of the base 1, which is convenient for adjusting the level of the worktable. The main shaft part is fixed by bolts on the base 1, the main shaft part includes the main shaft case 16, the main shaft case 16 upper end is equipped with the main shaft case cover 8, the main shaft 9 is installed in the main shaft case 16, and the front end of the main shaft 9 is equipped with the front end bearing 15 , the outer ring of the front end bearing 15 is fastened together with the main shaft housing 16 through the main shaft front cover 11, the rear end of the main shaft 9 is equipped with a rear end bearing 17, and the outer ring of the rear end bearing 17 is tightly connected to the main shaft housing 16 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com