Method for processing local dead pixels of superconducting tape in high-temperature superconducting narrow pile line

A technology of high-temperature superconducting tapes and superconducting tapes, applied in the usage of superconducting elements, superconducting/high-conducting conductors, superconducting devices, etc., to achieve the effect of reducing power transmission efficiency and increasing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

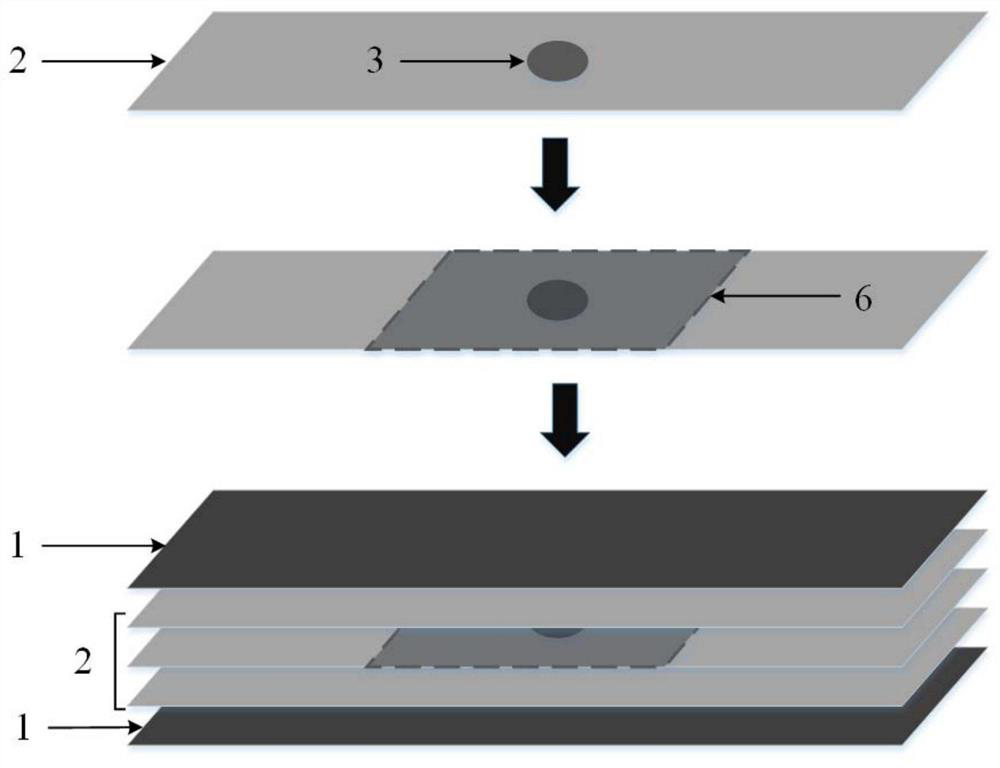

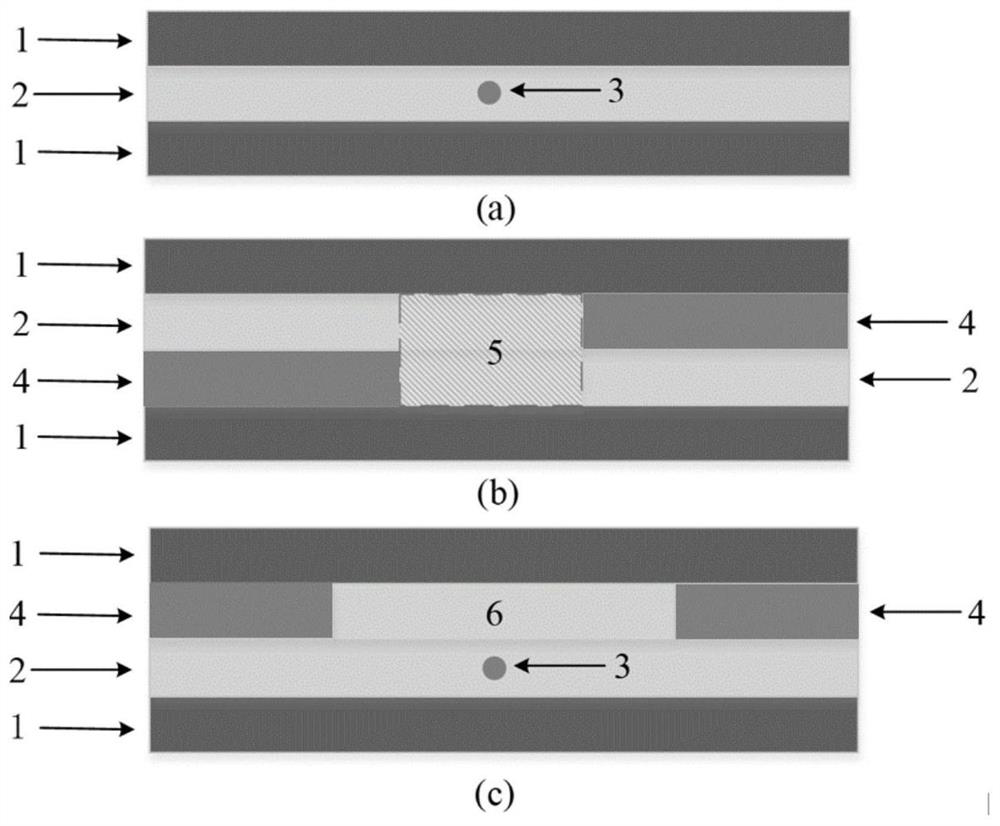

[0040] This embodiment provides a method for processing local dead spots of superconducting strips in a high-temperature superconducting narrow stack line; figure 1 is a process flow chart, wherein, the local dead spot 3 is located on the second-generation high-temperature superconducting strip 2 to be tested, and the second-generation high-temperature superconducting strip sample is attached to the local bad spot of the second-generation high-temperature superconducting strip 2 to be tested. At point 3, the second-generation high-temperature superconducting strip 2 to be tested is located between the red copper strip 1 and the red copper strip 1, and the second-generation high-temperature superconducting strip 2 to be tested attached to the second-generation high-temperature superconducting strip sample is stacked After encapsulation, a superconducting interlayer 6 is formed.

[0041] The specific method is as follows:

[0042] Prepare narrow stack wire materials: the second...

Embodiment 2

[0047] Prepare narrow stack wire materials: the second-generation high-temperature superconducting tape to be tested 2, the second-generation high-temperature superconducting tape sample, and the copper tape 1.

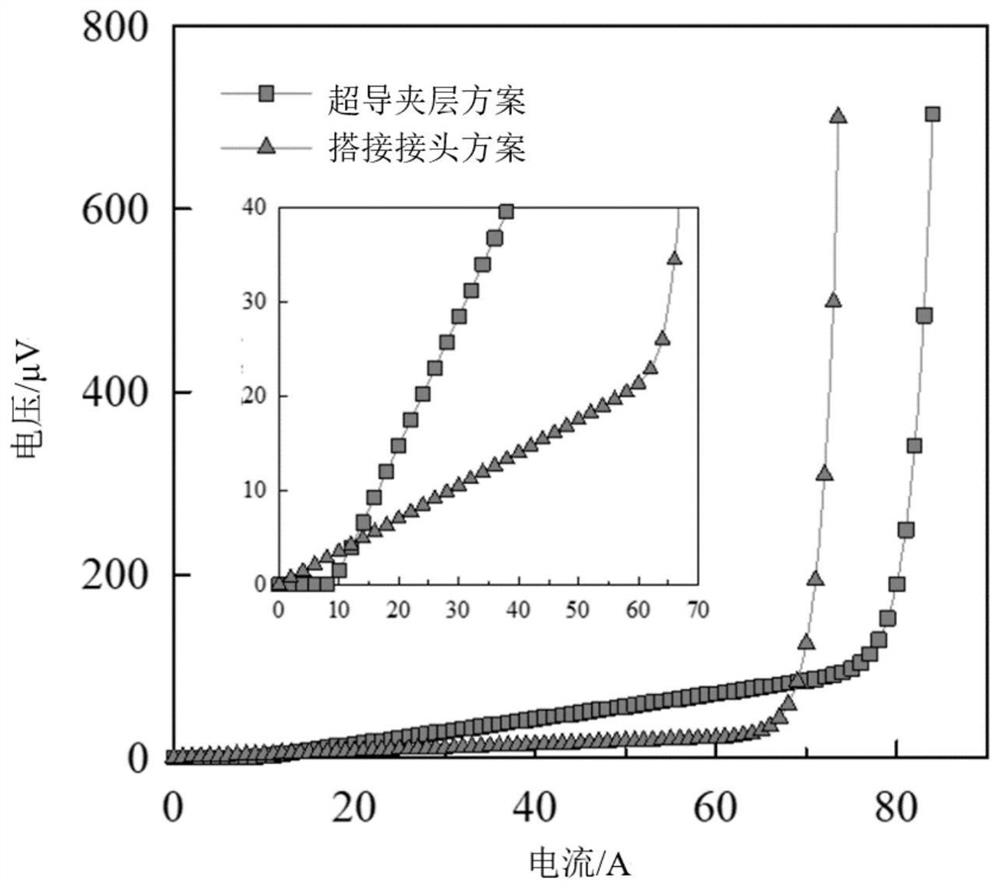

[0048] S1, measure the critical current of the second-generation high-temperature superconducting strip 2 to be tested, the critical current Ic decays from the original 70A to the area of local dead spots 3 at 10A, and the length of this dead spot area is 10mm; the width is 2mm.

[0049] S2. Face-to-face attachment of superconducting tape: select a second-generation high-temperature superconducting tape sample with a length of 20 mm and a width of 2 mm, and attach the selected second-generation high-temperature superconducting tape sample to the surface by diffusion pressing in a face-to-face manner. The dead point area of the second-generation high-temperature superconducting strip 2 to be tested. The fabrication of the diffusion press joint is the same as in Ex...

Embodiment 3

[0052] Prepare narrow stack wire materials: the second-generation high-temperature superconducting tape to be tested 2, the second-generation high-temperature superconducting tape sample, and the copper tape 1.

[0053] S1. Measure the critical current at each place of the second-generation high-temperature superconducting strip 2 to be tested. The critical current Ic has decayed from the original 70A to the area of local bad spots 3 at 10A. The length of the dead spot area is 18.18mm; the width is 2mm.

[0054] S2. Face-to-face attachment of superconducting tape: select a second-generation high-temperature superconducting tape sample with a length of 20 mm and a width of 2 mm, and attach the selected second-generation high-temperature superconducting tape sample to the surface by diffusion pressing in a face-to-face manner. The dead point area of the second-generation high-temperature superconducting strip 2 to be tested. The fabrication of the diffusion press joint is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com