Bearing fault intelligent diagnosis method for digital twin system

A fault diagnosis and bearing technology, which is applied in the field of intelligent diagnosis of bearing faults for digital twin systems, can solve problems such as insufficient cost of misclassification of fault samples, difficulty in misclassification costs, etc., and achieve the effect of real-time monitoring of health status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

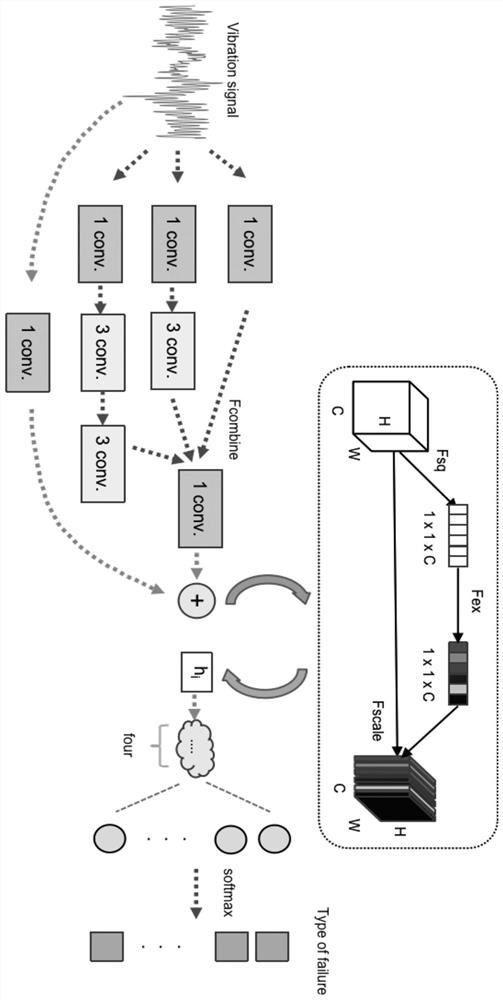

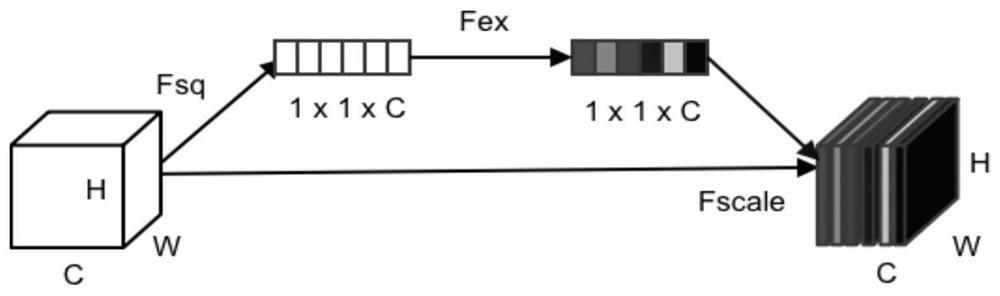

Method used

Image

Examples

Embodiment

[0041] In order to complete the training of the bearing fault diagnosis network constructed in the embodiment of the present invention, so as to better realize the detection of the target bearing, firstly, relevant data sets are collected for network parameter training and performance testing.

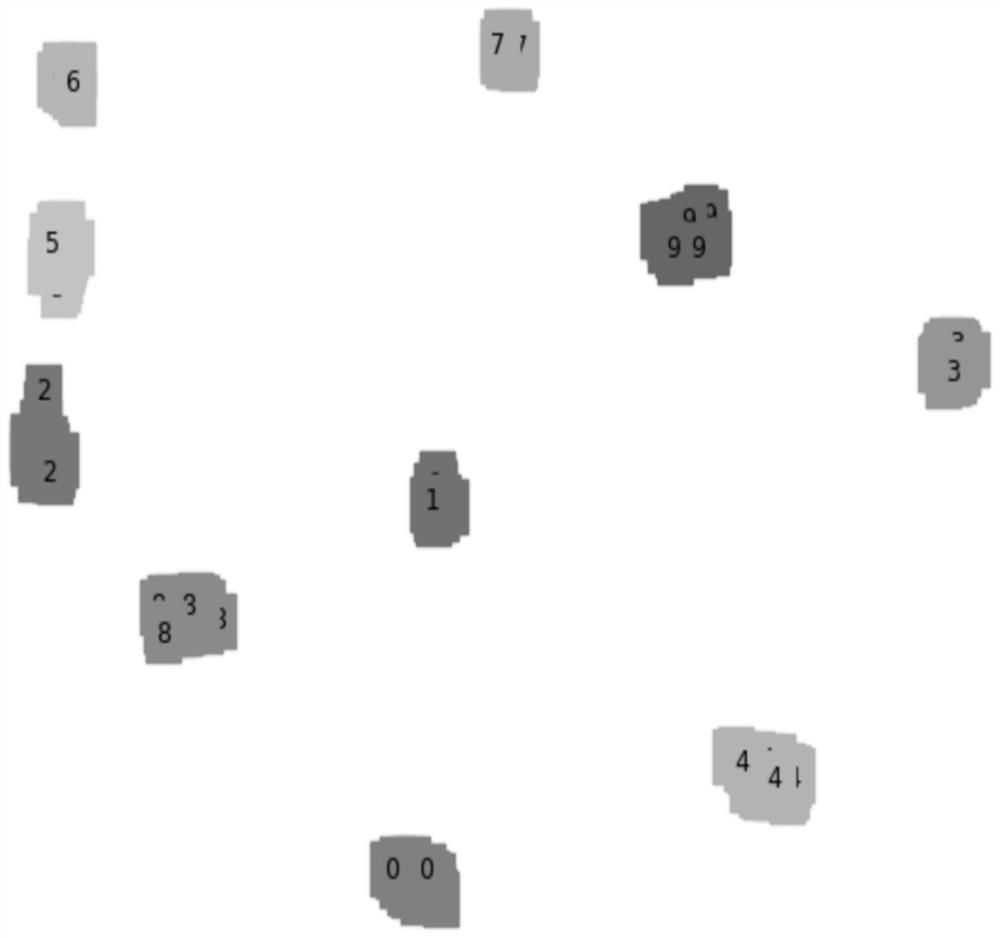

[0042] Collect the vibration signals of the bearings in the digital twin system under 9 fault states and 1 normal state. Different types of bearing vibration data are given different labels as a domain, and are cut at the same time to form samples and divide them according to the unbalanced ratio. It is the training set, verification set and test set; specifically, it includes the following steps:

[0043] (1) Collect the vibration signals of bearings in the state of rolling element fault B, outer ring fault OR and inner ring fault IR, the fault diameters are 7, 14 and 21 mils and the normal state, in order to improve the generalization ability of the model , add Gaussian white noise, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com