Universal joint pin and claw fork assembling all-in-one machine of transmission shaft and specific implementation method of universal joint pin and claw fork assembling all-in-one machine

A cross shaft and transmission shaft technology, applied in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of high labor intensity, low efficiency, and inability to meet production capacity requirements, so as to reduce labor intensity, liberate labor, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The accompanying drawings of the description are the preferred ways of implementing the present invention. The integrated machine for assembling the cross shaft of the transmission shaft and the claw yoke and its specific implementation method will be further described below in conjunction with the accompanying drawings.

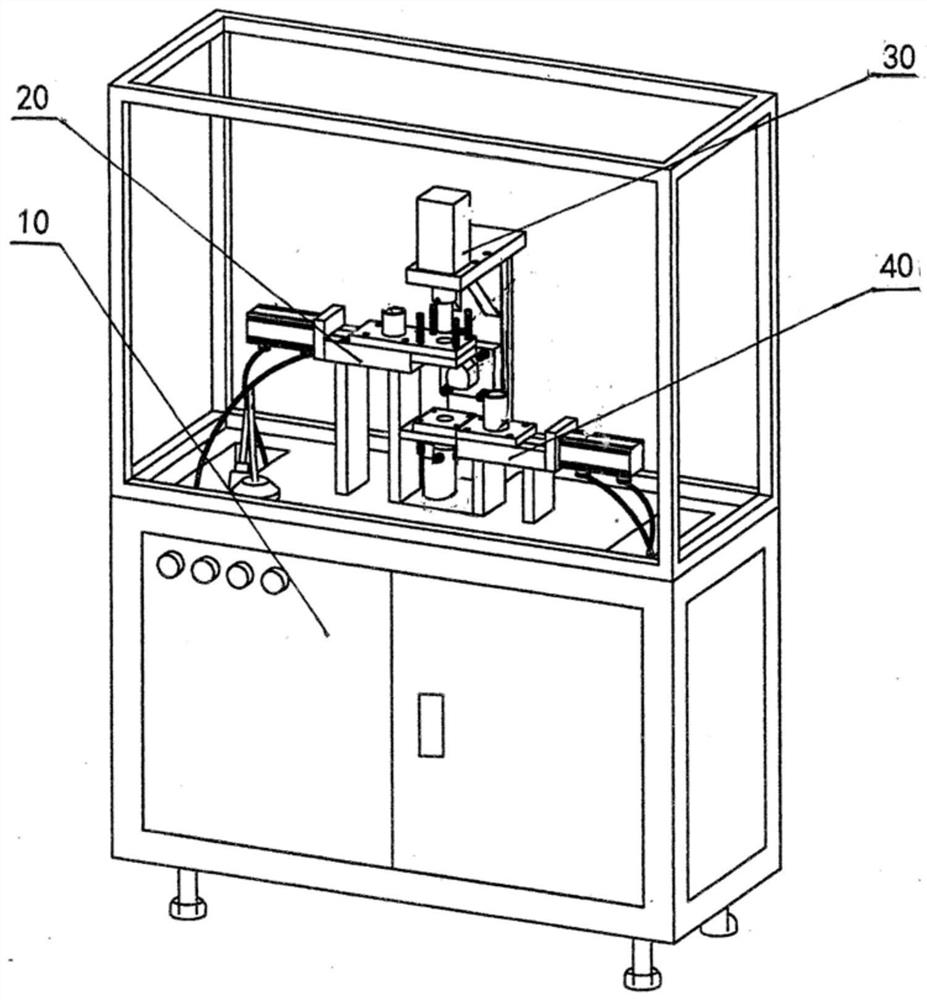

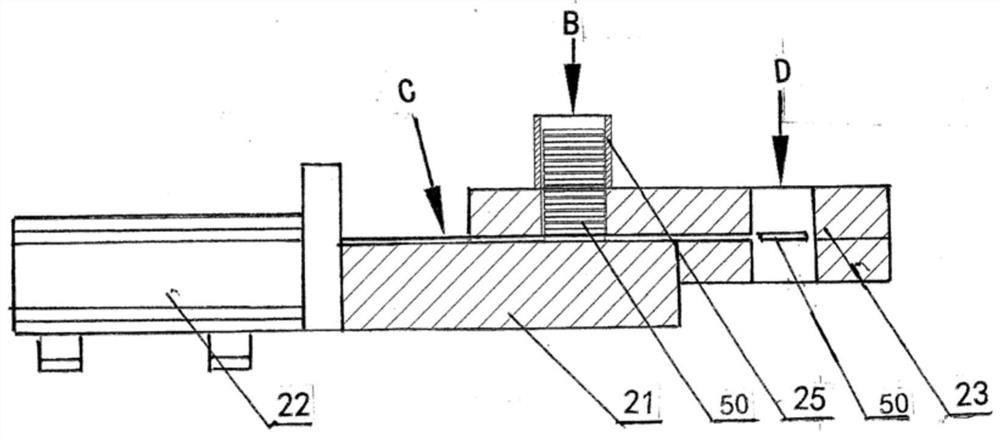

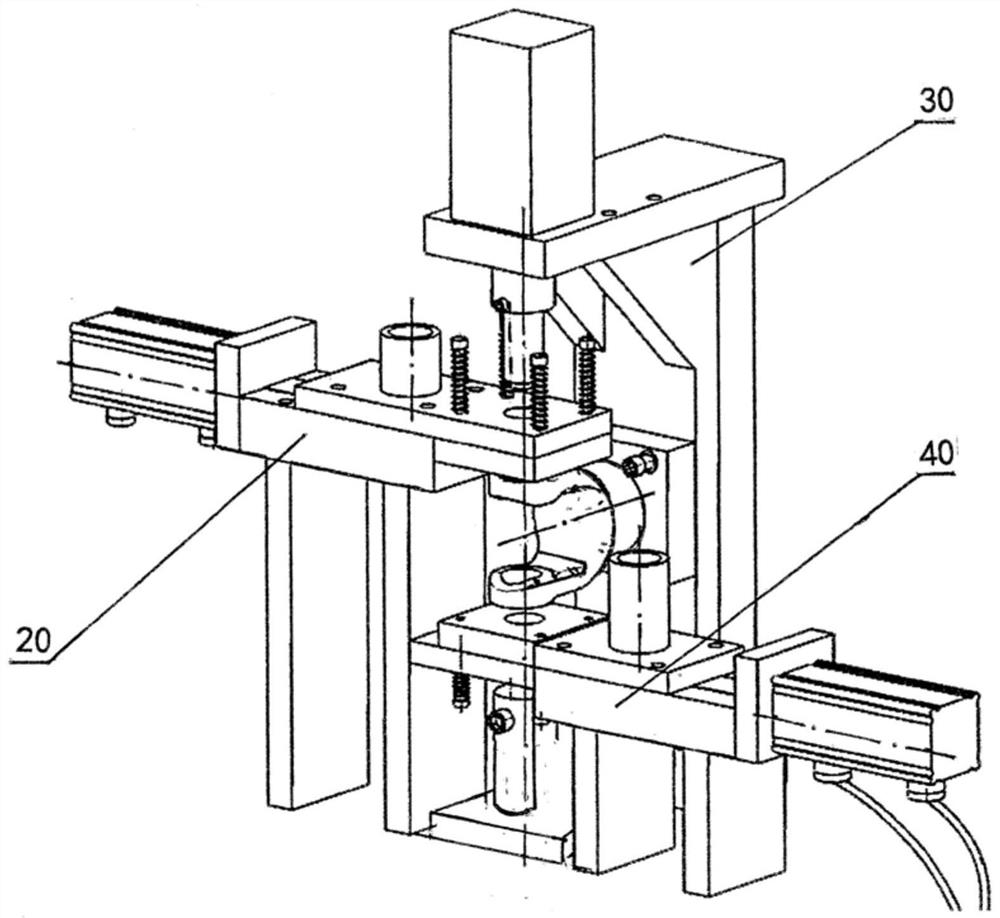

[0023] as attached figure 1 , 3 Shown: a cross shaft of a transmission shaft and a horn fork assembly machine of the present invention, including a stand 10, the stand 10 is a rectangular body, the upper part of the stand 10 is a rectangular support, and the lower part of the stand 10 is a rectangular hexahedron, It is characterized in that: the table top of the stand 10 has a first circlip placement tooling assembly 20, a hydraulic tooling assembly 30, a second circlip placement tooling assembly 40, a first circlip placement tooling assembly 20, a hydraulic tooling assembly 30, a second clip The spring placement tool assemblies 40 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com