PCB polishing device for intelligent manufacturing

A PCB board and polishing device technology, which is applied in the direction of manufacturing tools, grinding drive devices, surface polishing machine tools, etc., can solve the problems of too much or too little polishing, affecting the polishing quality of the PCB side surface, and poor fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

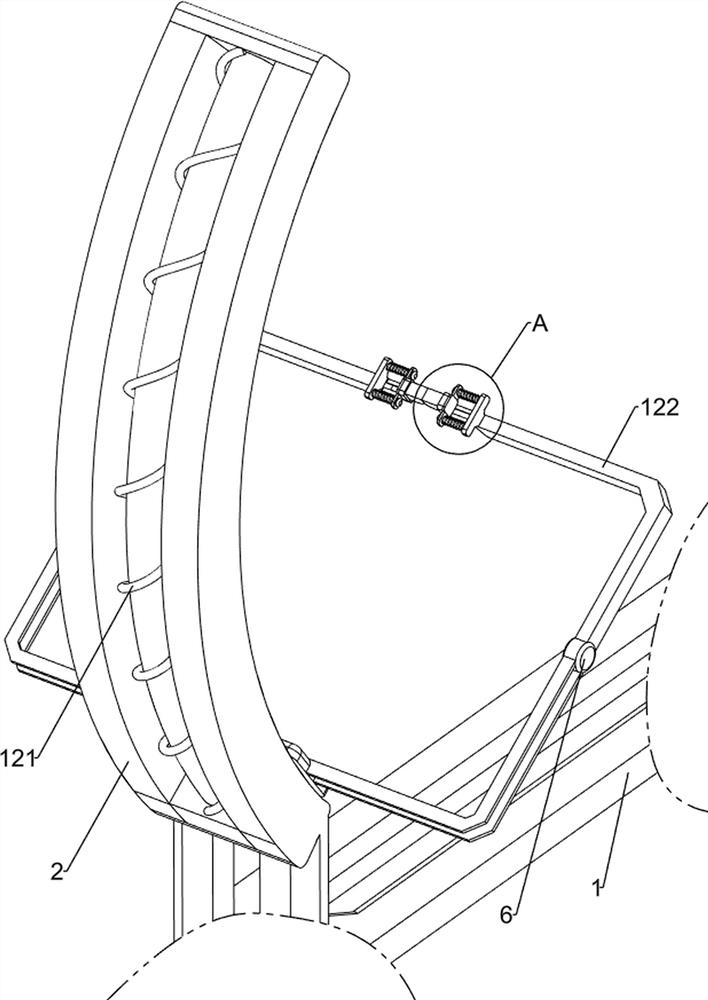

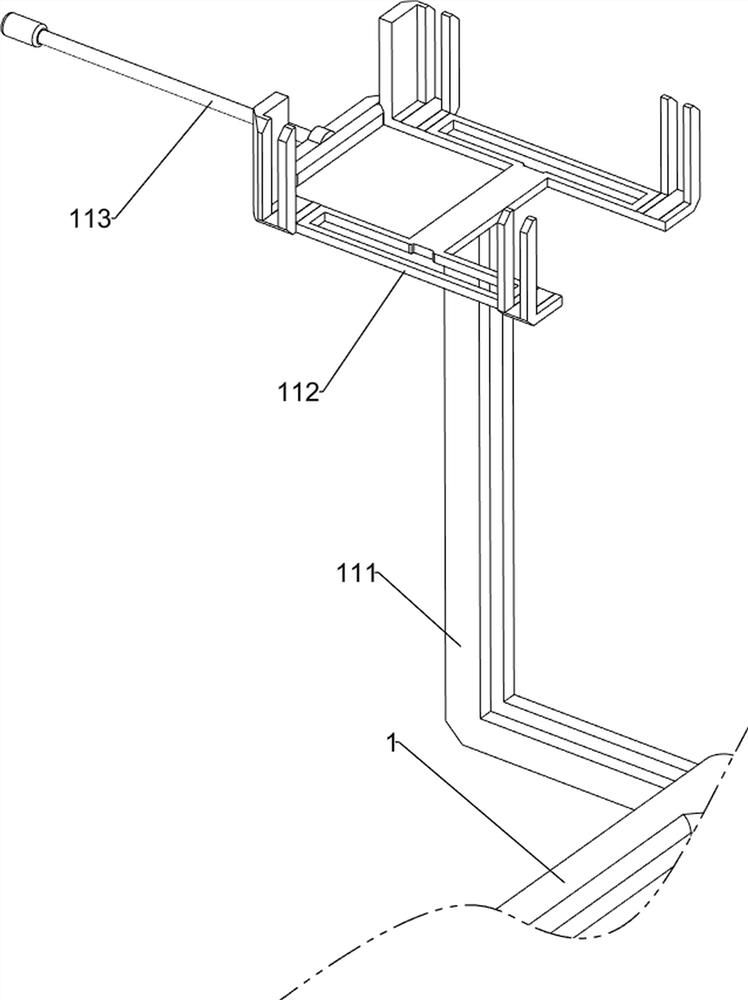

[0075] A kind of PCB board polishing device for intelligent manufacturing, such as Figure 1-4 As shown, it includes a bottom plate 1, a first slide rail 2, a first slide bar 3, a first movable block 4, a biaxial motor 5, a first support frame 6, a friction disc 7, a first belt 8, a rotating mechanism 9 and Clamping mechanism 10, bottom plate 1 upper front side is provided with first slide rail 2, and first slide rail 2 is provided with first slide bar 3, and first slide bar 3 is provided with first movable block 4 slidingly, and first The rear side of the movable block 4 is equipped with a biaxial motor 5, and the left and right sides of the first movable block 4 are symmetrically provided with a first support frame 6, and the rear sides of the two first support frames 6 are all rotatably provided with a friction disc 7, and the biaxial motor 5 A first belt 8 is connected between the output shafts on the left and right sides and the friction disc 7 on the same side through a ...

Embodiment 2

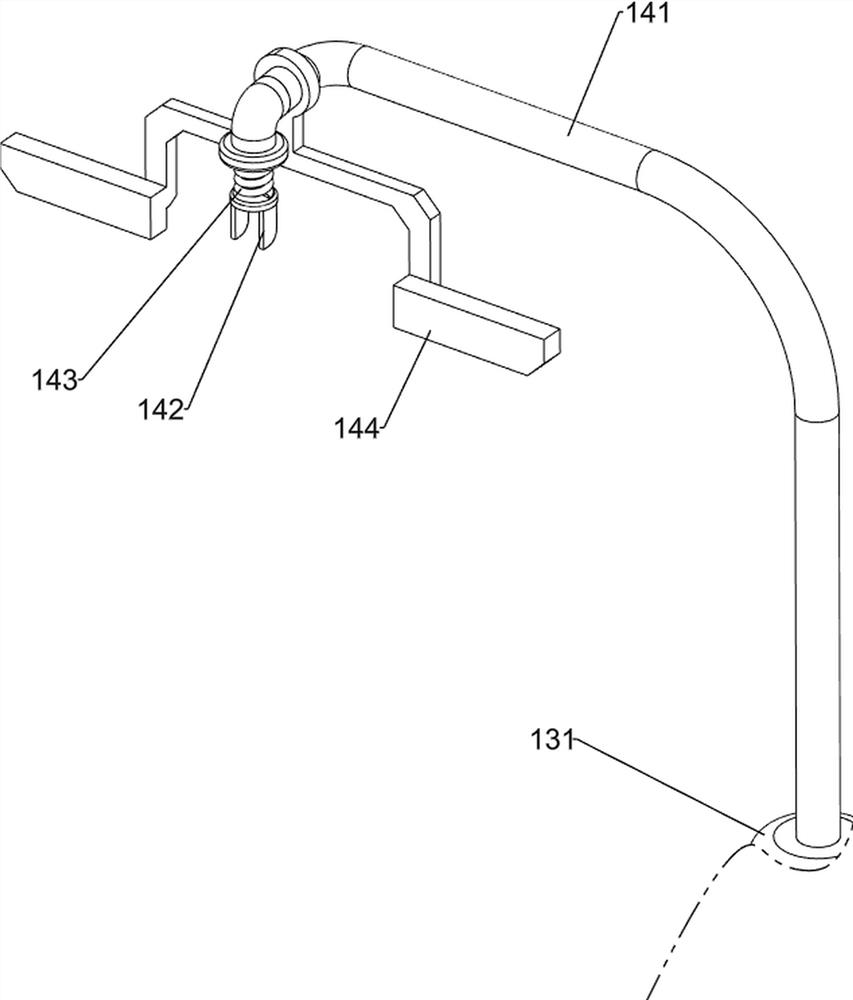

[0082] On the basis of Example 1, such as figure 1 , Figure 5-10 As shown, a pusher mechanism 11 is also included, and the pusher mechanism 11 includes a fourth support frame 111, a material receiving frame 112 and a first push plate 113, and the left side of the bottom plate 1 is provided with a fourth support frame 111, and the fourth The top of the support frame 111 is provided with a receiving frame 112 , and the lower part of the left side of the receiving frame 112 is slidably provided with a first push plate 113 , and the first push plate 113 cooperates with the pressing plate 102 .

[0083] People first put the PCB board to be polished on the receiving frame 112, and then people manually push the first push plate 113 to the right, and the first push plate 113 will drive the PCB board to move to the right, and then manually pull the pressure plate 102 to move upward, so that The PCB board is located between the supporting plate 96 and the pressing plate 102, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com