Shaftless propeller sediment deposition prevention device based on sediment-carrying channel

A thruster and anti-sediment technology, which is applied in the direction of propulsion engine, ship propulsion, propulsion components, etc., can solve the problems of increasing power consumption, reducing cruising range, and affecting overall performance, so as to reduce energy loss and structural wear, The effect of improving operating efficiency and reliability, improving filtration efficiency and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] In the description of the present invention, terms such as "upper", "lower", "inner", "outer", "left", "right", etc. indicating orientation or position are based on the orientation shown in the drawings, and are only for simplification. describe, rather than indicate or imply that the invention must have a particular orientation or position.

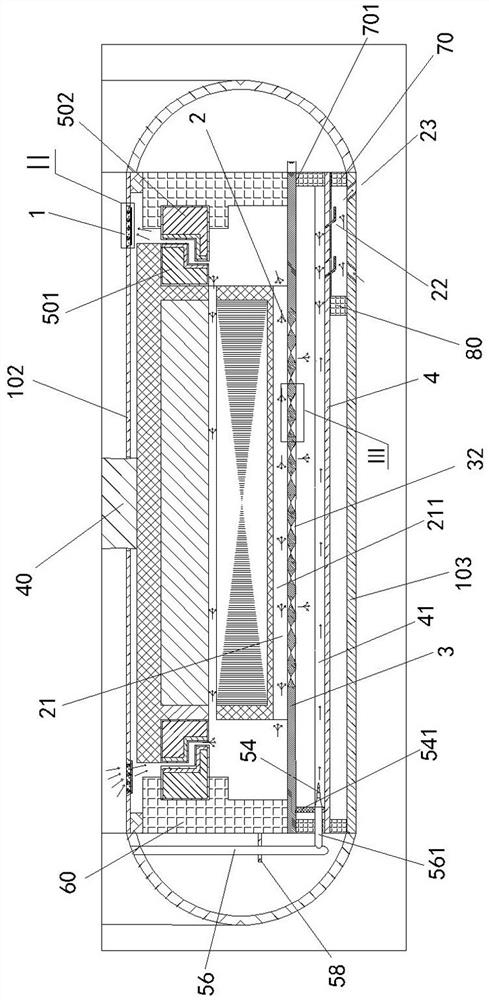

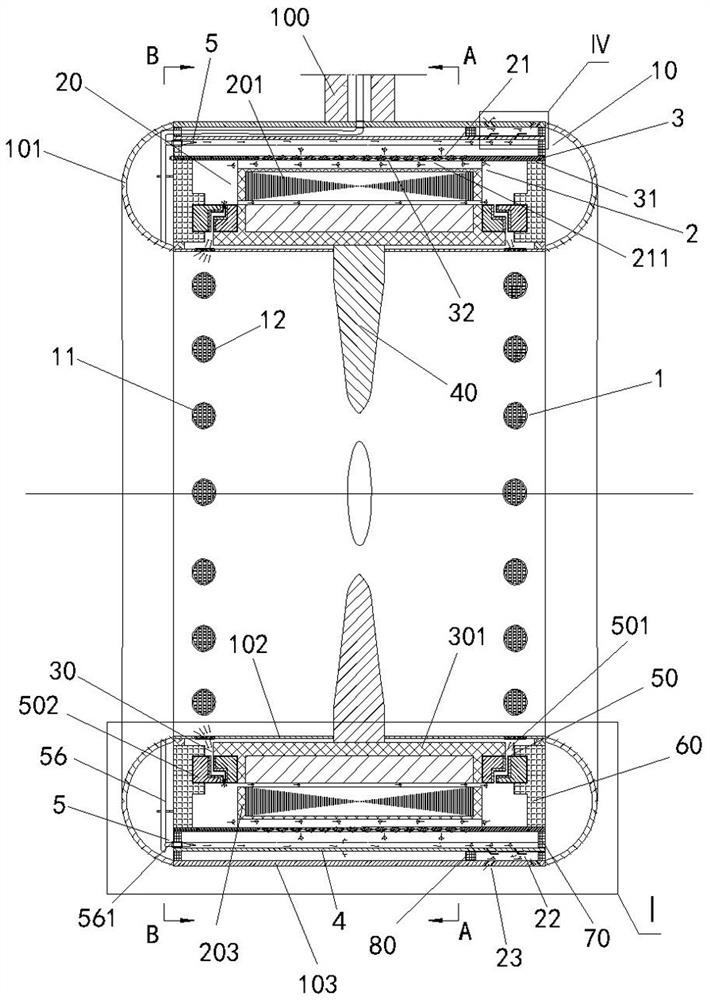

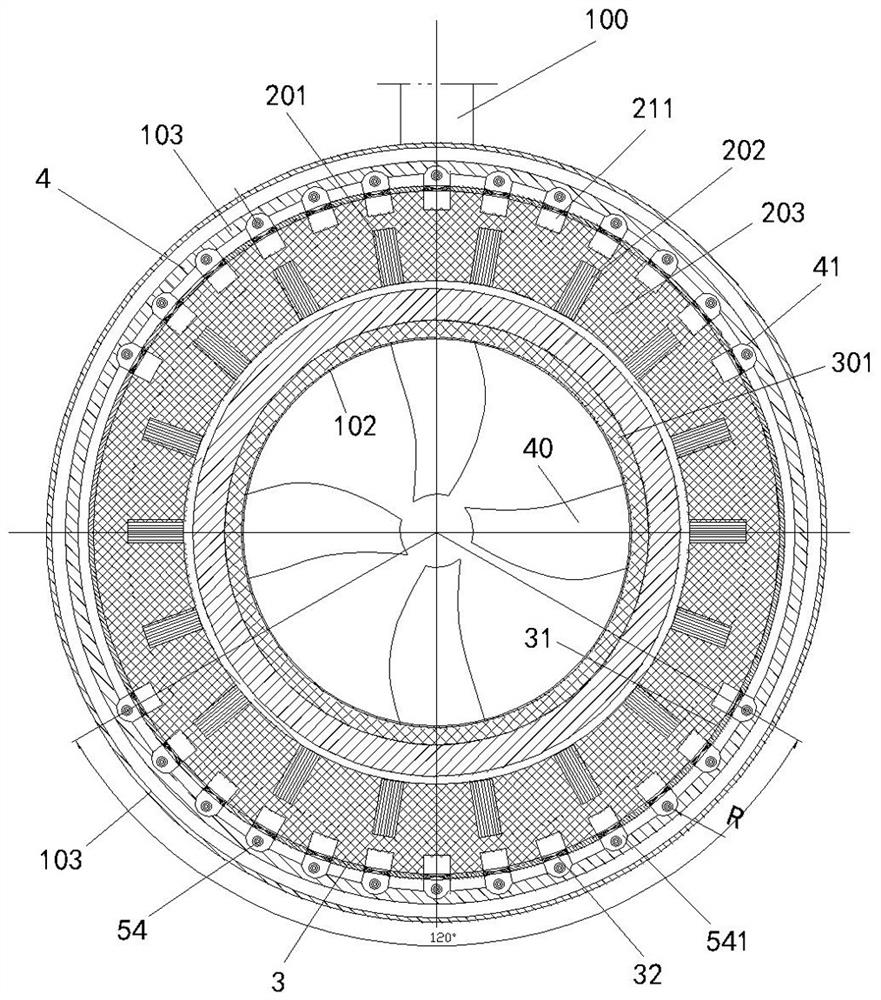

[0030] Such as Figure 1 ~ Figure 4 As shown, the present embodiment includes a filter mechanism 1 arranged at both ends of the inner wall of the conduit shell 102, a sediment discharge mechanism 2 arranged in the conduit 10, and a high-pressure water flushing mechanism 5 arranged inside and outside the stern and in the conduit 10 . Such as Figure 4As shown, the filter mechanism 1 includes frustum-shaped holes 11 and grid filter screens 12 arranged in groups, the frustum-shaped holes 11 are evenly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com