A front-end feeding manipulator for porous brick assembly and its working method

A technology of porous bricks and manipulators, applied to manipulators, conveyors, manufacturing tools, etc., can solve problems such as complex structures, inconvenient maintenance, and low efficiency, and achieve the effects of reducing overall weight, reducing installation space, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

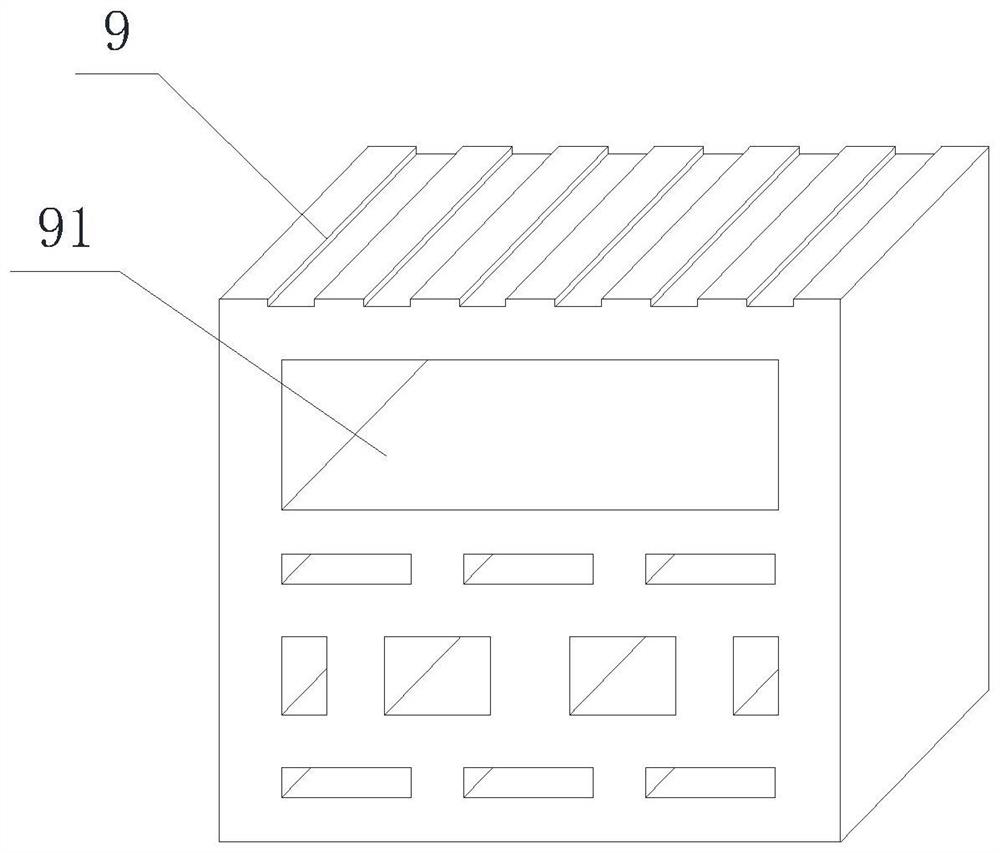

[0059] Our company has developed a perforated brick with thermal insulation board, see figure 1 , which includes a perforated brick, the perforated brick 9 has a main hole 91 with a larger size, the main hole runs through the perforated brick, the main hole is rectangular, and its length direction is parallel to the length direction of the perforated brick. , the holes on the perforated brick are oriented up and down, the length direction of the main hole is parallel to the wall, and a thermal insulation board is embedded in the main hole. At the same time, there are also a plurality of small holes on the porous brick, which can reduce the overall weight on the one hand, and also have a certain thermal insulation and sound insulation function on the other hand.

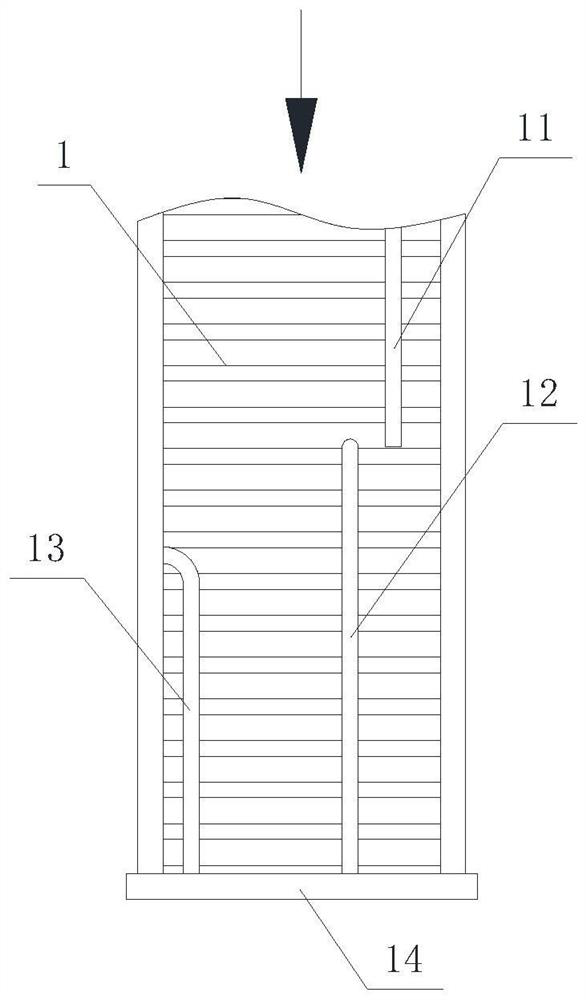

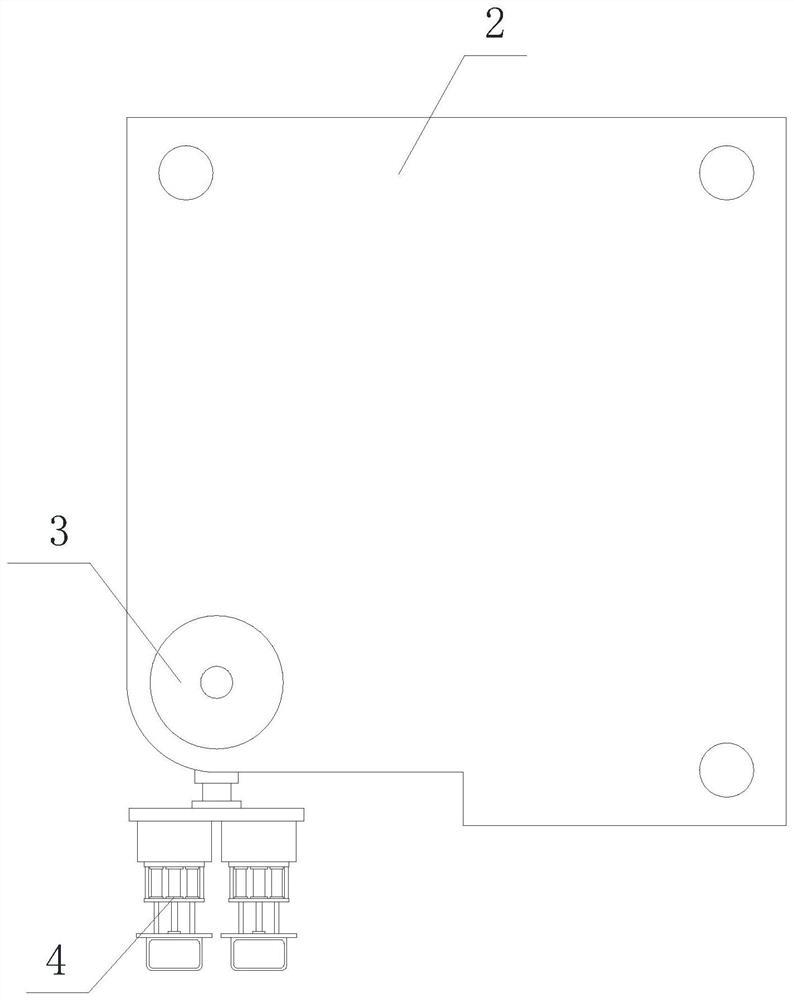

[0060] In order to realize the automatic assembly of the thermal insulation board in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com