A Simple Hydraulic Oscillation Tool

An oscillating tool, a simple technology, applied in the direction of vibration drilling, etc., can solve the problems of short service life, complex structure, etc., and achieve the effect of good smoothness, high oscillation frequency and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

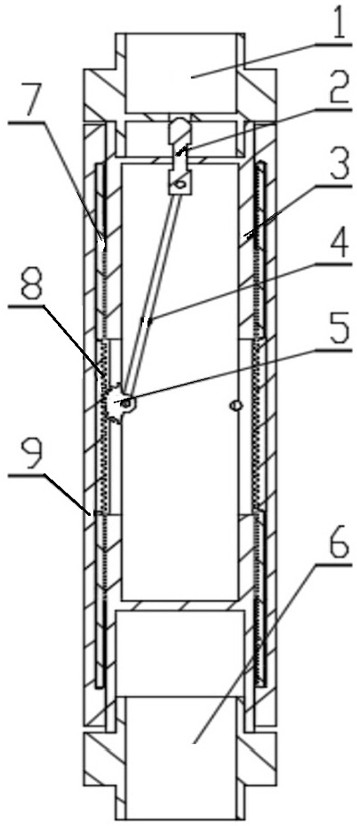

[0031] Below in conjunction with accompanying drawing, the present invention is further described:

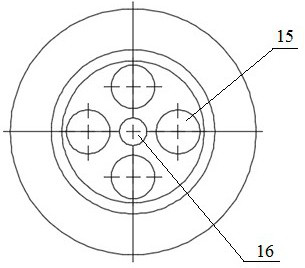

[0032] combine Figure 1-Figure 12 As shown, this hydraulic oscillating tool includes a current-limiting upper connecting cylinder 1, a current-limiting push head 2, a protective inner cylinder 3, a linkage rod 4, a driving gear 5, a driven rack 8, a ring wall disc spring 7, a movement outer The tube 9, the lower connecting tube 6, the current limiting upper connecting tube 1 is threadedly connected above the protection inner tube 3, the lower part of the protection inner tube 3 is threadedly connected with the upper end of the lower connecting tube 6, and the lower end of the current limiting upper connecting tube 1 has an annular step outside, and the lower The outer part of the upper end of the connecting cylinder 6 has the same annular step, and the moving outer cylinder 9 surrounds the protection inner cylinder 3 and freely falls on the annular step outside the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com