Self-calibration method and system under complete machine condition of engineering machinery gearbox

A construction machinery, self-calibration technology, applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problem of neglecting influence, etc., to achieve compensation inconsistency, good shifting smoothness, and smooth clutch engagement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: the condition parameter selects the turbine speed as an example;

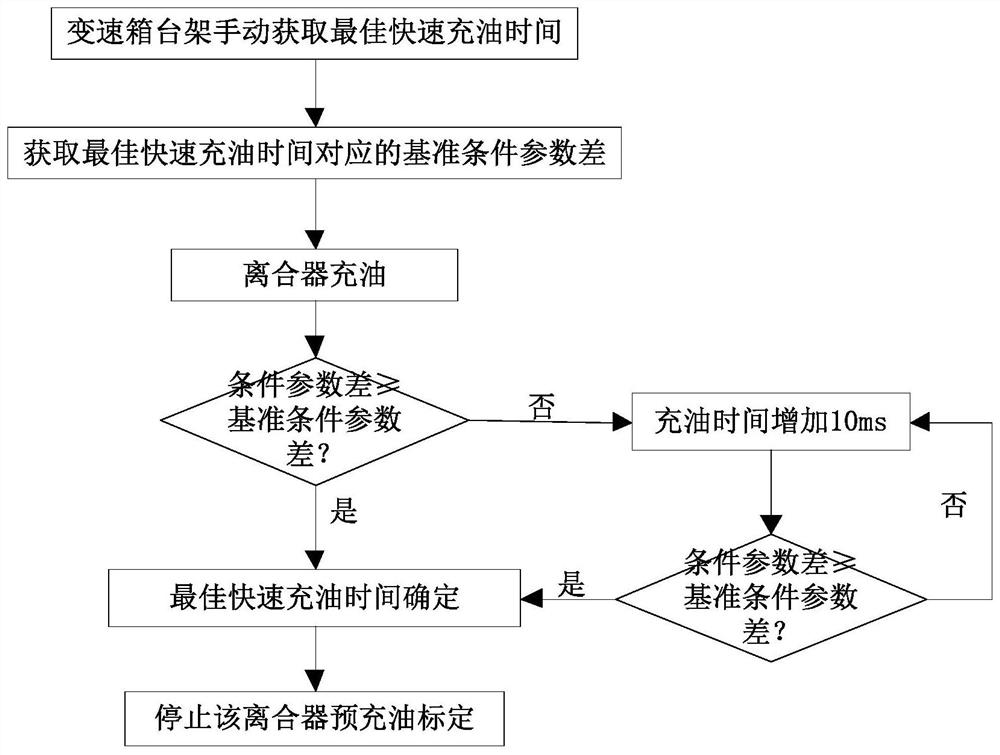

[0051] The flowchart of an embodiment of the present invention is as follows figure 2 As shown, the specific steps are as follows:

[0052] (1) Manually adjust the fast oil filling time of the clutch on the gearbox test bench to make the clutch engage smoothly, and take this time as the theoretical oil filling time T of the clutch CK ;

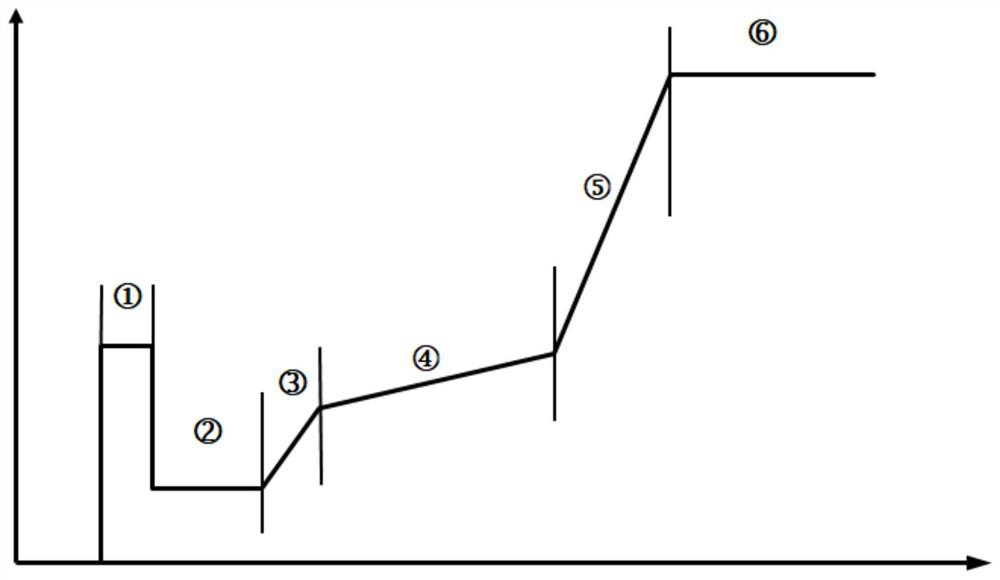

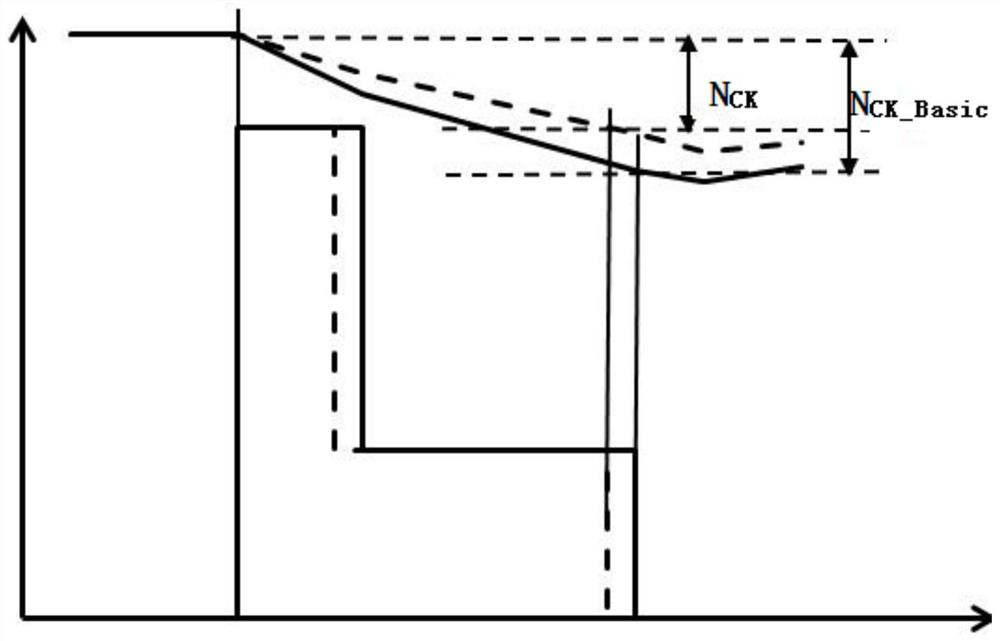

[0053] (2) Based on the theoretical oil filling time T CK The clutch is filled with oil as the benchmark, and the oil filling curve selects the first two stages of the clutch engagement process, such as image 3 shown. Acquisition pressure curve start time t s and end time t e The corresponding turbine speed, get the reference turbine speed difference N CK_Basic , forming a reference turbine speed difference strategy table and storing it in the gearbox control unit;

[0054] (3) When the state of the whole machine satisfies the self-calibration pre...

Embodiment 2

[0059] A self-calibration system under the condition of a construction machinery gearbox, including a controller, the controller includes a memory and a processor, the memory is used to store instructions, and the instructions are used to control the processor to operate to perform the above-mentioned Self-calibration method under the condition of complete construction machinery gearbox.

[0060] In some embodiments, the memory also stores a reference condition parameter difference.

[0061] In some embodiments, the self-calibration system under the condition of the complete construction machinery gearbox further includes: a shift handle, a parking brake, a transmission control unit, an engine control unit, a temperature sensor, a rotational speed sensor, and a self-calibration control unit ;The shift handle, parking brake, transmission control unit, engine control unit, temperature sensor, speed sensor, and self-calibration control unit are all connected to the controller,

...

Embodiment 3

[0069] A loader includes the above-mentioned self-calibration system under the condition of the complete machine of the construction machinery gearbox.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com