Simulation optimization design method for hot-blowing snow-removing exhaust device of turbofan engine

A turbofan engine and exhaust device technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problems of increasing the cost of jet snow removal vehicles, small effective exhaust width, and inability to achieve fast snow removal, etc., to achieve Improve the effect of blowing snow and melting ice, reduce the amount of optimization calculation, and improve the effect of snow removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0083] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the content disclosed in the specification for the understanding and reading of those familiar with this technology, and are not used to limit the conditions for the implementation of the present invention , any modification of structure, change of proportional relationship or adjustment of size shall still fall within the scope covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. .

[0084] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit the scope of this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present inve...

Embodiment 1

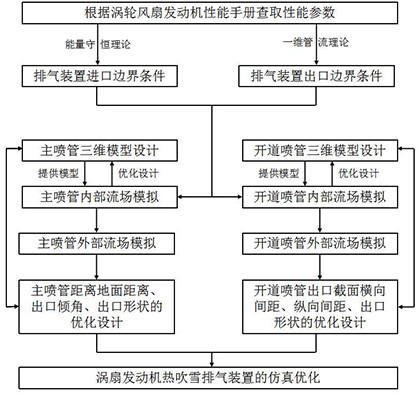

[0086] Such as figure 1 As shown, the invention discloses a simulation optimization design method of a turbofan engine thermal blowing snow removal exhaust device, comprising the following steps:

[0087] Step 1: Determine the inlet boundary conditions and outlet boundary conditions of the thermal blowing snow removal exhaust device based on the turbofan engine modification; check the performance parameters according to the turbofan engine performance manual, and then determine the inlet boundary conditions of the exhaust device through the energy conservation theory, Determine the outlet boundary conditions of the exhaust device according to the one-dimensional pipe flow theory;

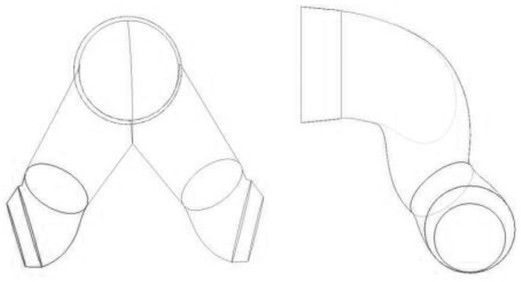

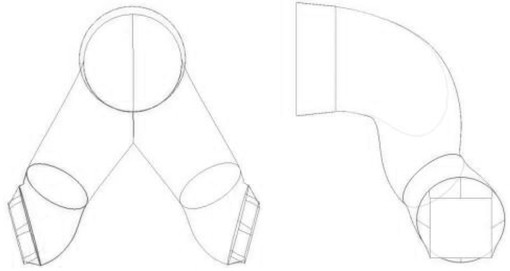

[0088] Step 2: Design the three-dimensional solid model of the main nozzle under different outlet cross-sectional shapes; that is, the three-dimensional model design of the main nozzle;

[0089] Step 3: According to the inlet boundary conditions and outlet boundary conditions described in step 1 an...

Embodiment 2

[0098] Preferably, the step 1 is specifically:

[0099] Step 1-1: Check the performance parameters according to the performance manual of the turbofan engine, and the performance parameters include: bypass ratio, total air flow, internal temperature, external temperature, total inlet pressure of the turbine, and drop-off pressure of the turbine under different working conditions specific and intrinsic pressure;

[0100] Step 1-2: According to the relationship between the bypass ratio and the total air flow, determine the internal air flow and the external air flow; according to the internal air flow, external air flow, internal temperature, external temperature, and ideal gas energy conservation theory, Determine the outlet temperature of the internal and external mixer, that is, the total temperature of the exhaust device inlet (equivalent to the total temperature in the exhaust device inlet boundary conditions); The pressure characteristic diagram of the internal and extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com