Efficient circulating sugaring system and sugaring method for preserved fruits

A high-efficiency technology for preserved fruit, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of uneven dipping of preserved fruit, uneven dipping effect, low production efficiency, etc., to promote the penetration of sugar liquid, avoid sugar liquid Browning, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

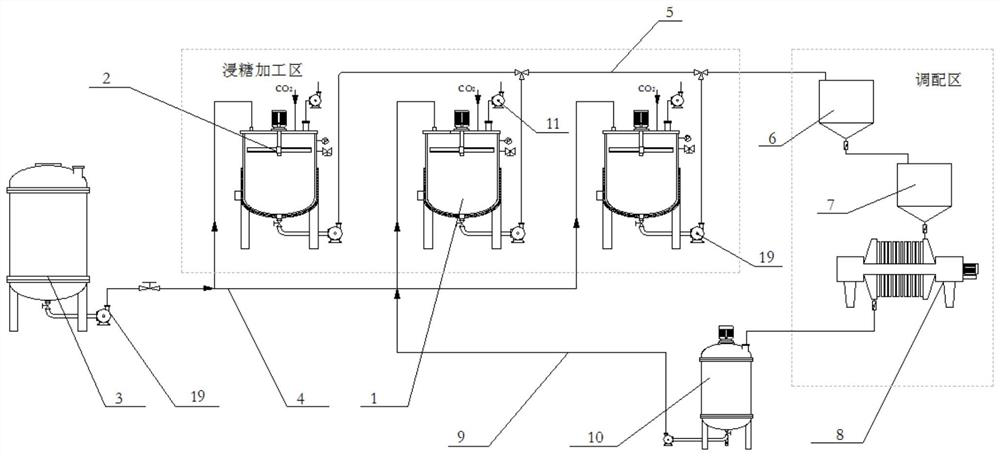

[0035] Such as Figure 1-4 As shown, a high-efficiency circulating sugaring system for preserved fruit includes a stock solution tank 3, a sugar soaking processing area and a deployment area. 4. Transport the sugar solution to each of the sugar soaking tanks 1, and the sugar solution after the sugar soaking in the sugar soaking tank 1 is transported to the deployment area through the recovery pipeline 5, and the preparation area includes sequentially connected enzymatic hydrolysis Tank 6, decolorizing tank 7 and filter press 8, the sugar solution recovered and processed by the preparation area is transported back to the sugar soaking processing area through the second infusion pipeline 9, and the second infusion pipeline 9 is also provided with sugar solution Conditioning tanks 10, each of the sugar soaking tanks 1 is respectively externally connected with a vacuum pump 11 and a carbon dioxide gas flushing system.

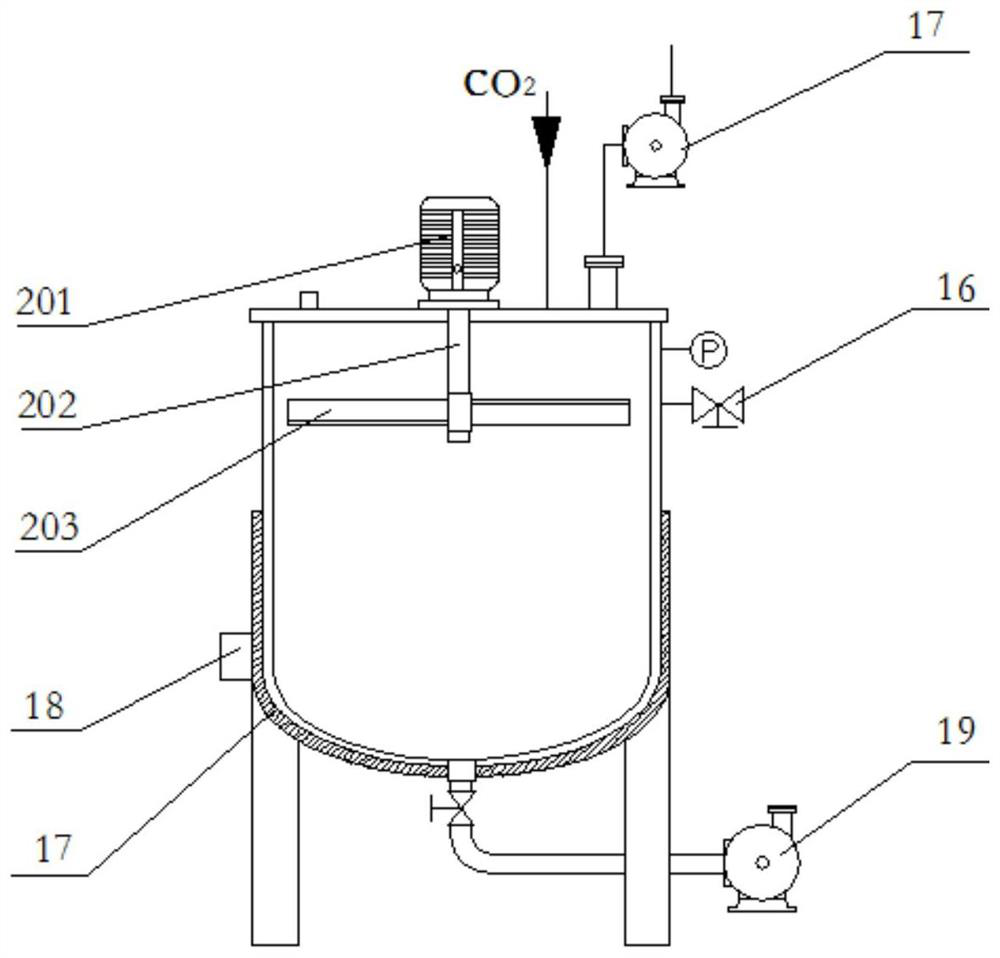

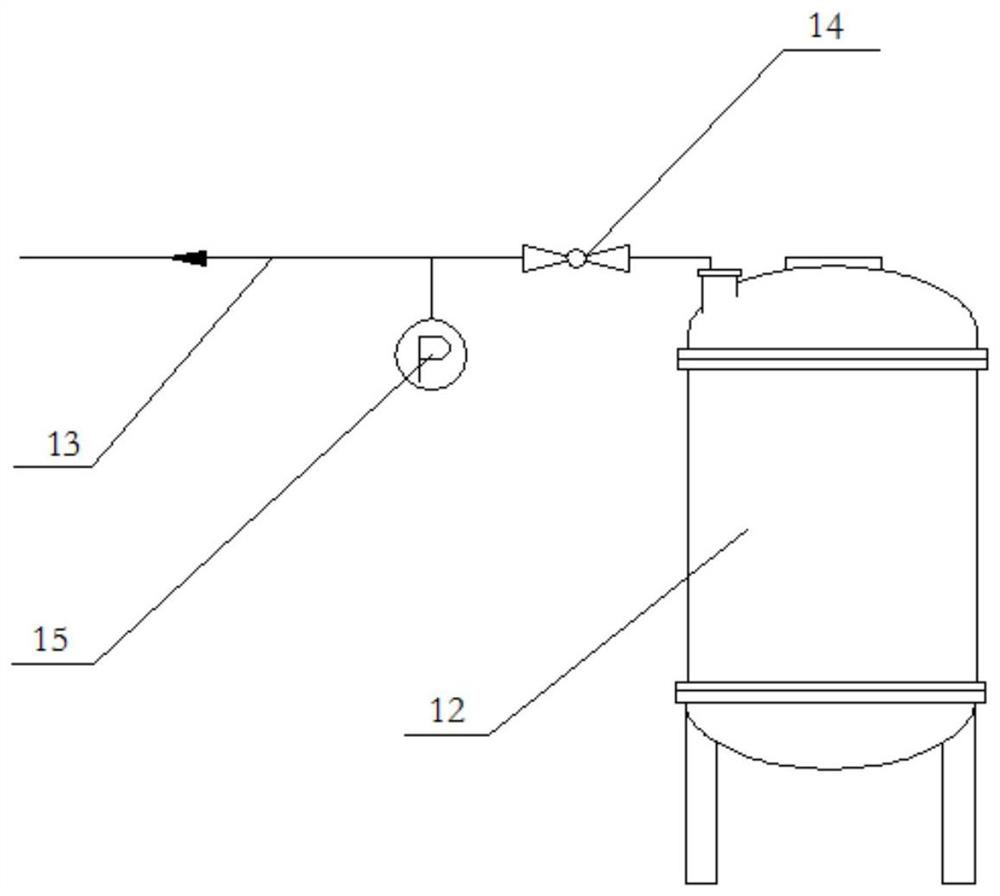

[0036] Such as image 3 As shown, in this embodiment, the c...

Embodiment 2

[0045] A high-efficiency cycle sugaring method for preserved fruit, specifically comprising the following steps:

[0046] S1. Put the cleaned preserved fruit (strawberry in this embodiment) into the sugar soaking tank, and transport the sugar solution in the raw liquid tank to the sugar soaking tank through the infusion circulation pump, and control the whole sugar soaking process through the temperature control system The temperature is 25-35°C;

[0047] S2. After soaking sugar at normal pressure for 1 hour, discharge the air in the sugar soaking tank through a vacuum pump to maintain the vacuum environment in the sugar soaking tank. The vacuum degree is -0.12MPa to -0.09MPa, and carry out sugar soaking for 1.5 hours;

[0048] S3. Rush carbon dioxide gas into the sugar soaking tank through the carbon dioxide flushing system until the pressure in the tank rises to 10Mpa. After maintaining the pressure for 0.5 hours, quickly release the pressure to release carbon dioxide. After...

Embodiment 3

[0053] The dried (cranberry) preserved fruit prepared in Example 2 was taken, and the preserved fruit obtained by direct atmospheric pressure immersion in sugar for 14 hours and drying was used as a control group to detect the sugar content.

[0054] Slice the dried preserved fruit to obtain 6 preserved fruit slices with the same thickness. The preserved fruit slices are numbered sequentially, and the sugar content of the preserved fruit slices is tested to realize the sugar content of different positions of the preserved fruit from the outside to the inside and then to the outside. Quantitative test, the test results are as follows:

[0055] Table 1 Detection of sugar content in preserved fruit slices

[0056]

[0057] As can be seen from Table 1, the difference in sugar content inside and outside the preserved fruit obtained by the direct normal pressure sugar immersion treatment of the control group is relatively large, and the sugar content on the outside of the preserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com