Cup water jet cutter lifting cleaning device

A cleaning device and water knife technology, which is applied in household cleaning devices, cleaning equipment, tableware washing machines/rinsing machines, etc., can solve the problem of increasing the cost of waste gas and wastewater discharge treatment, difficulty in controlling the amount of detergent used, and the danger of detergent to the body Health and other issues, to achieve the effect of improving cleaning efficiency and hygiene, improving efficiency, and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

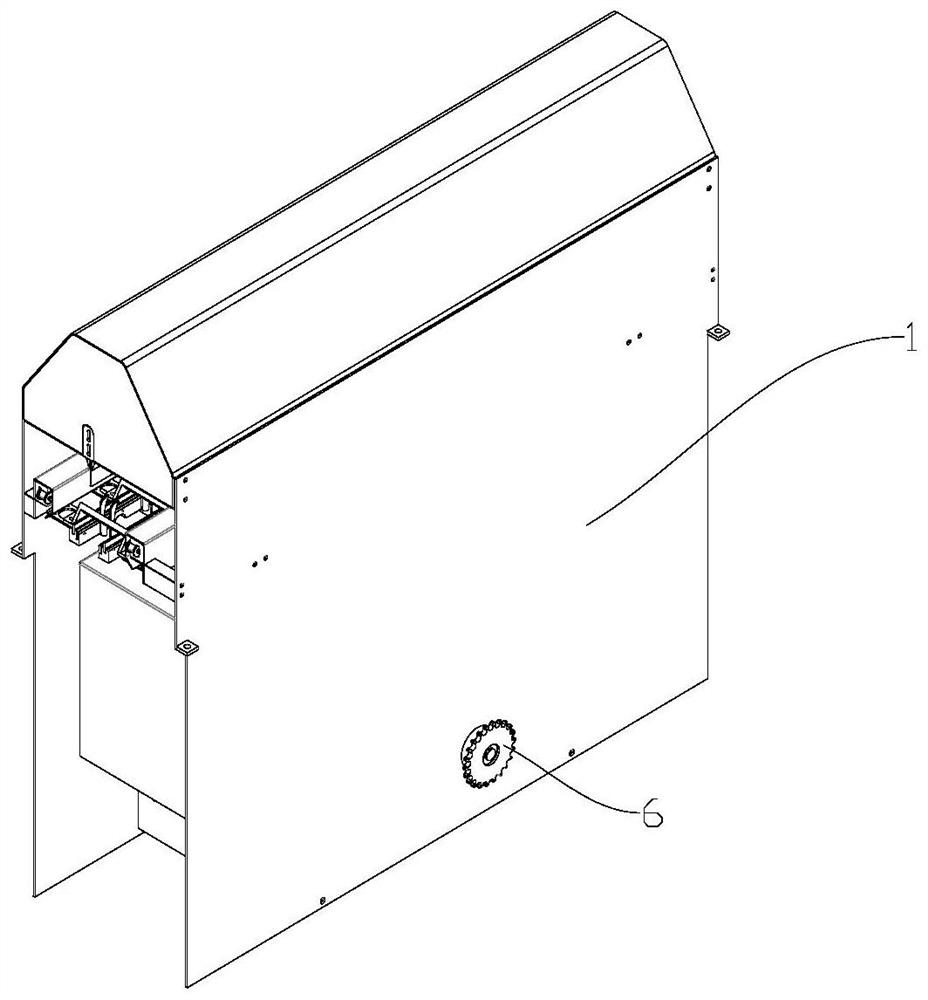

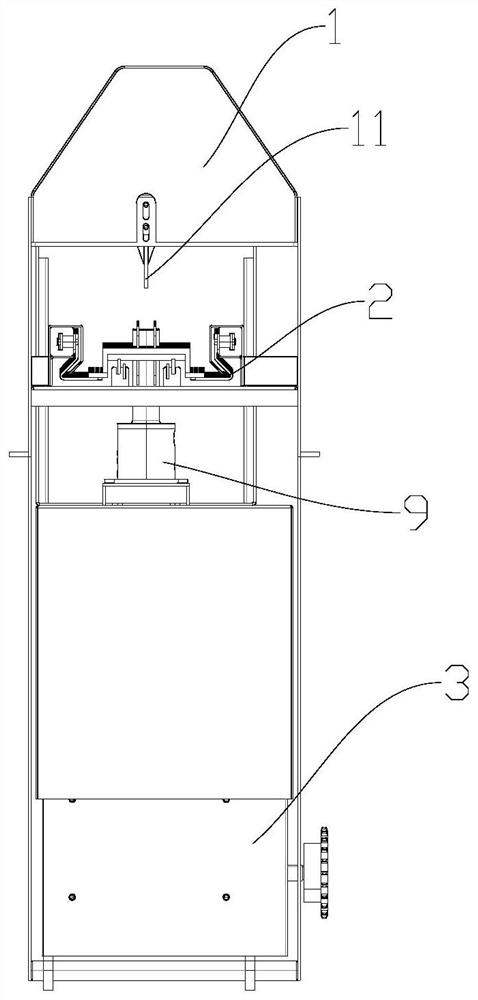

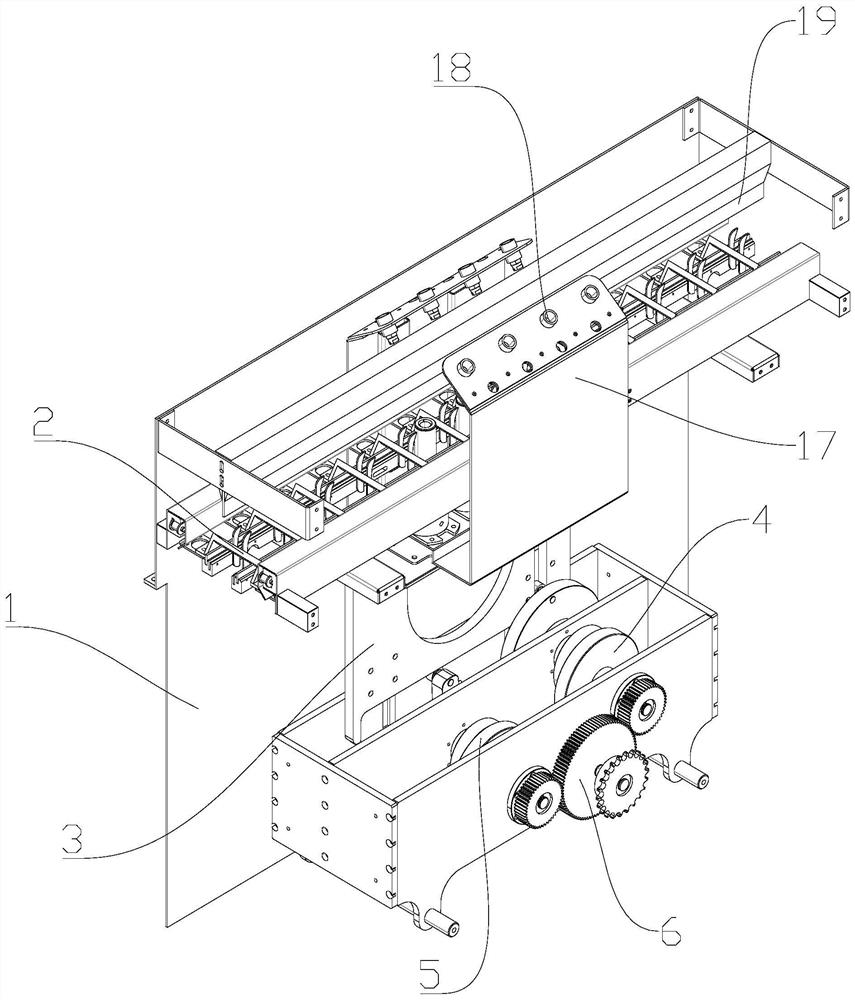

[0033] Please refer to Figure 1 - Figure 6 The present application provides a cup of water knife lifting cleaning device, including a body 1 for cleaning a first flushing mechanism for cleaning the interior wall of the tableware and a second flushing mechanism for cleaning the outer wall of the tableware, the upper end of the body 1 A transmitting mechanism 2 is provided to convey the cutlery, and the above-described transmitting mechanism 2 is provided with a synchronous lifting mechanism that moves the first flushing mechanism and the second rinse mechanism and cooperates with the moving mechanism 2, and the above first rinse is washed. The mechanism is provided below the transfer mechanism 2, and the second flushing mechanism is provided above the transfer mechanism 2.

[0034]In the present embodiment, the body 1 serves as a support carrier to provide a stable support to the device, ensuring that the equipment can be stably operated, and the transfer mechanism 2 is provided on...

Embodiment 2

[0037] Please refer to Image 6 According to the first embodiment, the present embodiment is provided to provide a cup of water knife lifting cleaning device, and the difference from Embodiment 1 is that the first flushing mechanism includes several cleaning seats 8, the cleaning seat 8 and the synchronous lifting mechanism Connecting, the central portion of the cleaning seat 8 slides a backward tube 9, and the top end of the cleaning seat 8 is provided with a water tool assembly for rinse the inner wall of the cup, and the bottom of the cleaning seat 8 is provided with the first entrance to the water knife assembly. The water port 12 is adjusted to the regulating assembly of the radio size of the above water knife assembly, and the above-described regulatory assembly is connected to the reverse flow tube 9.

[0038] In the present embodiment, the cleaning seat 8 is connected to the synchronous lifting mechanism, and the cleaning seat is moved together by the synchronous elevator, ...

Embodiment 3

[0041] Please refer to Image 6 Based on the second embodiment, the present embodiment is provided to provide a cup of water knife lifting cleaning device, and the difference from Example 2 is that the water knife assembly includes a nozzle 10 provided at the top end ring wall of the cleaning seat 8 and is located The ring water spray port 11 of the top outer wall of the above cleaning seat 8, wherein the ring water spray port 11 is formed between the top end of the cleaning seat 8 and the reverse flow tube 9.

[0042] In the present embodiment, a nozzle 10 is provided on the top end ring wall of the cleaning seat 8, and a high-speed high-dense water jet water tool can be generated by the nozzle 10, and the inner bottom wall of the cup can be effectively cleaned, and the outer wall of the top end of the cleaning seat 8 is provided. The ring water spray port 11 is provided, and a high-speed high-dense water jet slider can be generated by a ring water slit 11, and the inner side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com