Manufacturing equipment and manufacturing method for anti-formaldehyde wallpaper

A technology for preventing formaldehyde and wallpaper, applied in special paper, paper, papermaking and other directions, can solve the problems of increased formaldehyde emission from the glued layer of wallpaper, increased labor intensity of staff, and increased glued surface of wallpaper, etc. The effect of maintaining stability, improving the practical application effect, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

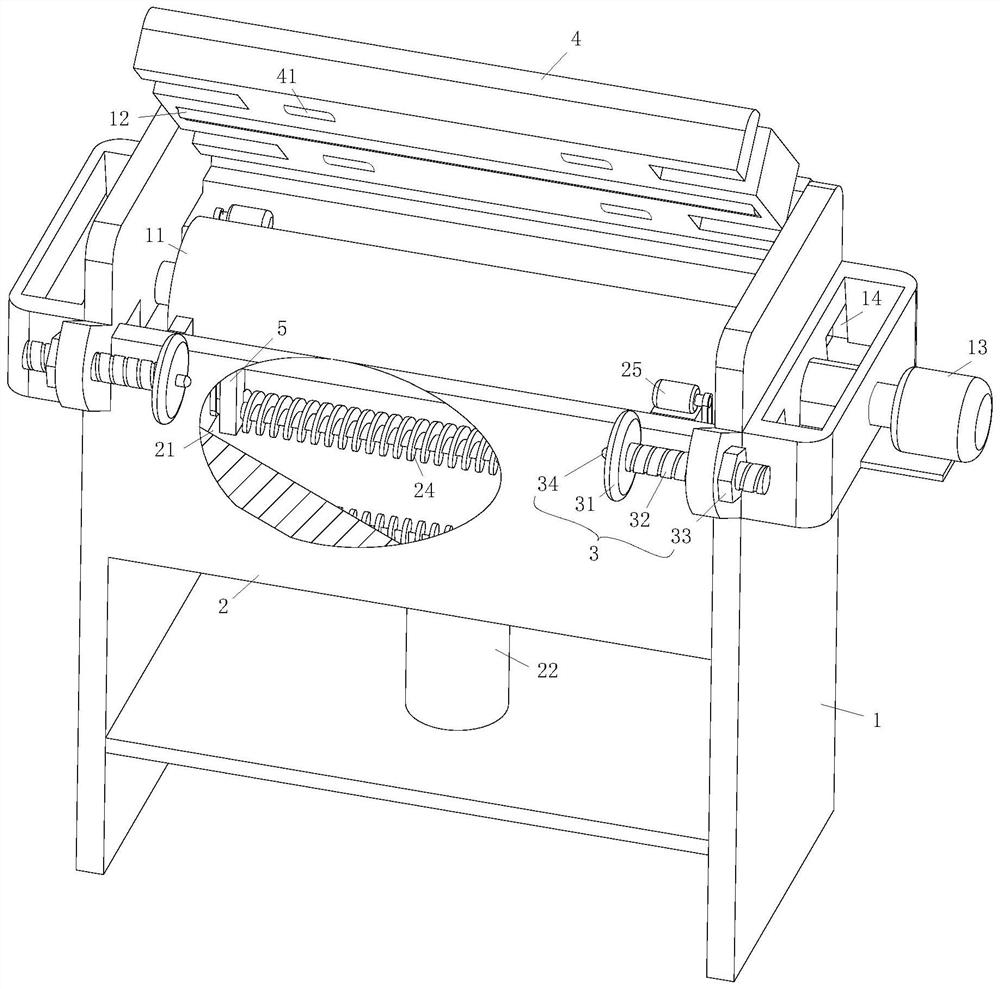

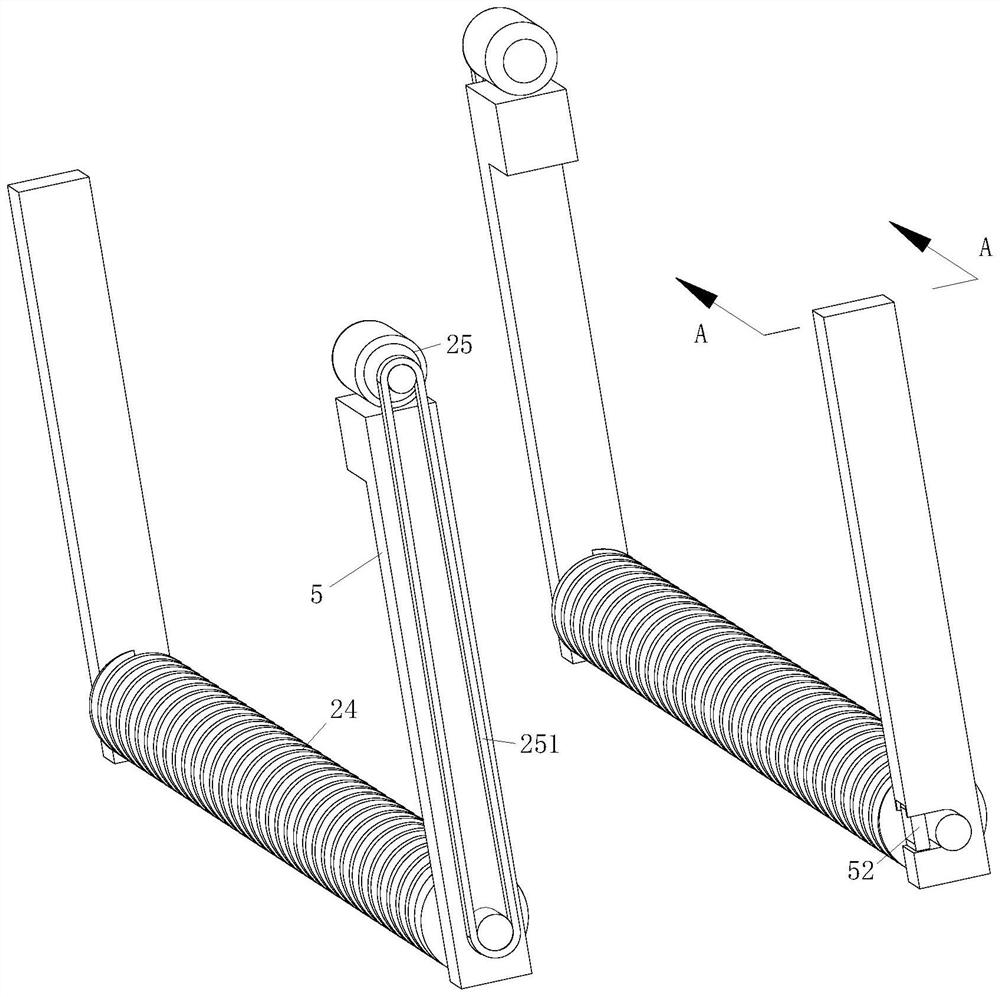

[0034] As an embodiment of the present invention, the upper end of the push plate 21 is fixedly connected with a support frame 5, the number of the support frames 5 is at least four, and every two support frames 5 are placed oppositely; There are screw rods 24 connected in rotation; the number of the screw rods 24 is two, and the two screw rods 24 are distributed on both sides of the gluing roller 11; the upper end of the support frame 5 is fixedly connected with a servo motor 25; the servo motor 25 The output shaft and the screw 24 are connected by a belt 251; when working, when the glue is poured into the glue box 2 through the feed port 14, the glue spreads over the screw 24, and the controller first controls the operation of the servo motor 25, so that The servo motor 25 drives the screw 24 to rotate through the belt 251, so that the glue flowing into the glue box 2 is quickly and evenly distributed in the glue box 2 under the conveyance of the screw 24, and then the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com