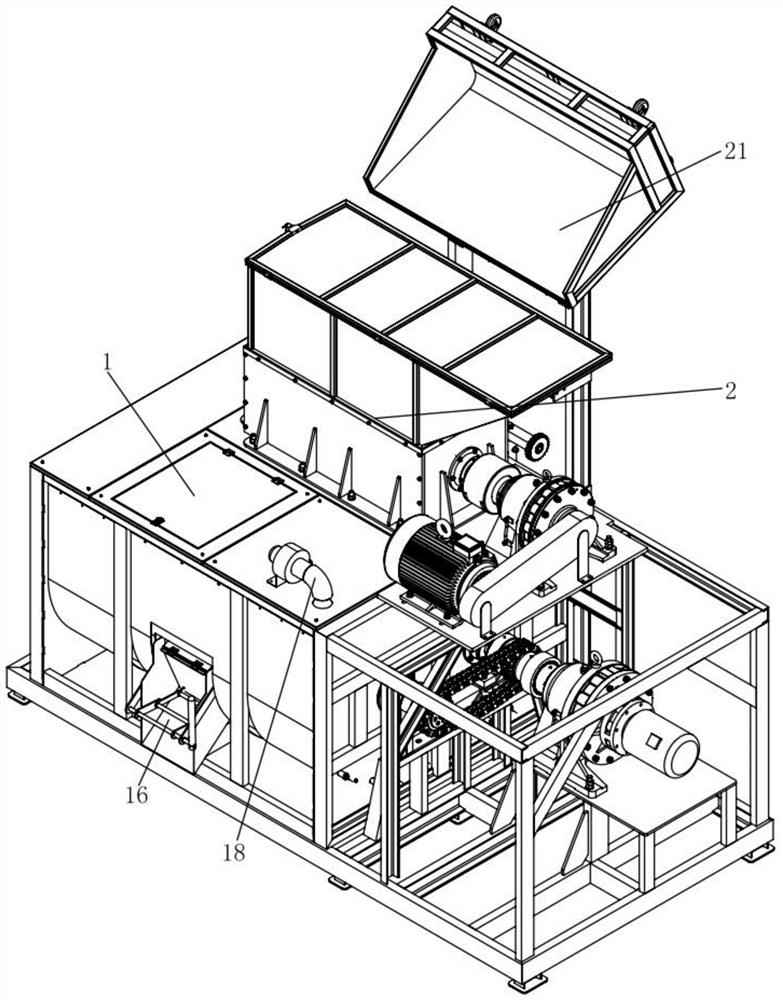

Animal carcass degradation method and animal carcass degradation machine

A technology for animal carcasses and degradation machines, applied in the field of animal carcass degradation methods and animal carcass degradation machines, which can solve the problems of increasing the operating process and operating time, increasing the load of the stirring shaft, and easily damaging the stirring shaft, so as to reduce the operating process and operation time, avoid overloading, and improve the effect of degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

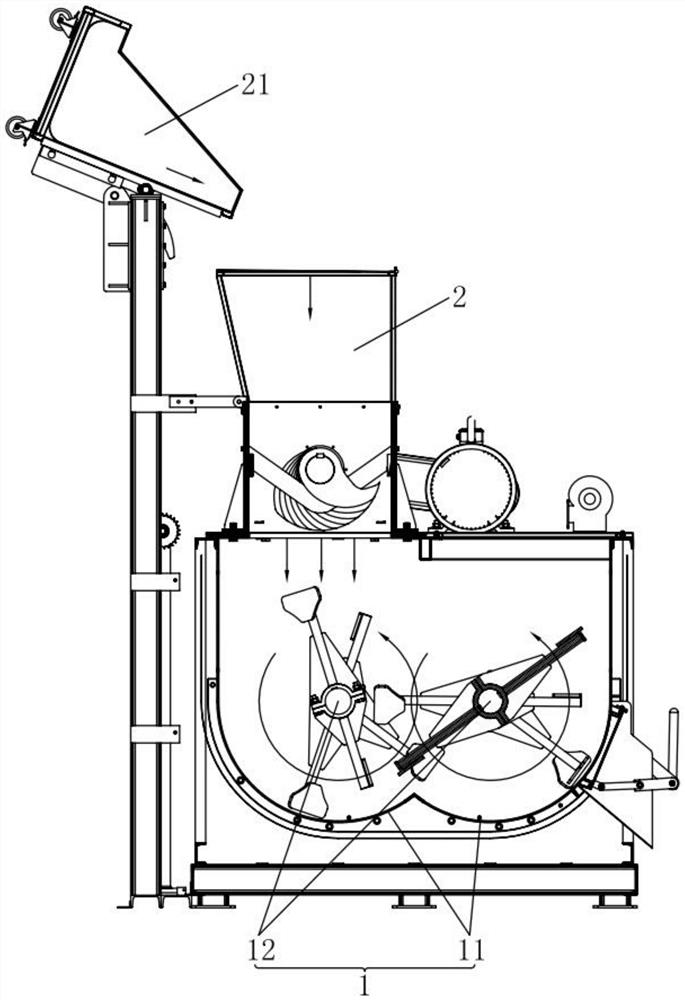

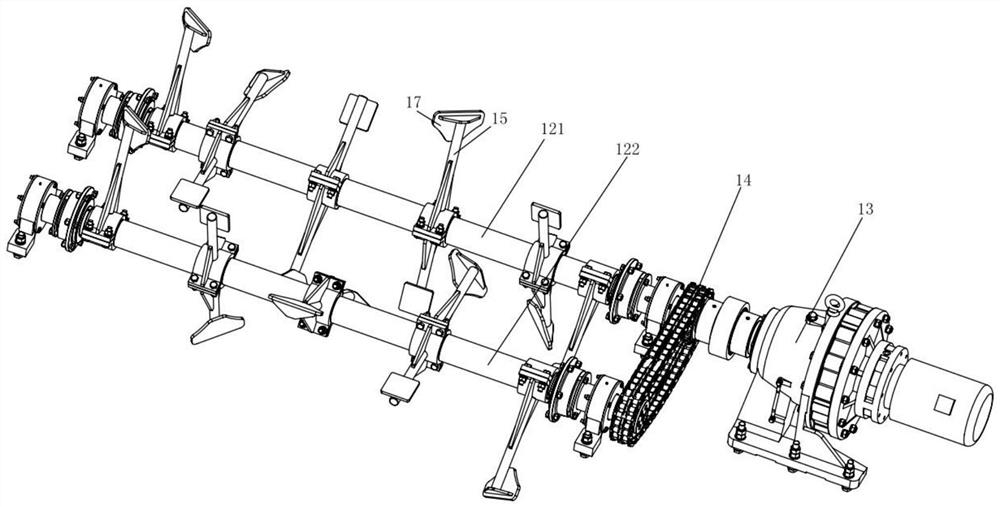

[0023] The invention provides a method for degrading animal carcasses. The animal carcasses are pre-broken into pieces, and the broken animal carcasses are stirred for primary degradation; while stirring, the animal carcasses are heated and degraded for the first time. The water vapor and waste gas generated in the process are exhausted by drafting. When large animal carcasses are degraded, the animal carcasses can be pre-crushed first, and the animal carcasses are broken into small pieces and then stirred and decomposed to improve the decomposition efficiency and avoid the occurrence of overloading. The pre-crushed animals The carcass is relatively small, so that more animal carcasses can be accommodated in the equipment without additional decomposition, which reduces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com