Method and device for rapidly improving cleanliness of steel ladle with cover

A cleanliness, ladle technology, applied in the improvement of process efficiency, manufacturing tools, mechanical cleaning, etc., can solve the problem of unmatched and connected ladle cleanliness, affecting driving efficiency and driving production rhythm, difficult to dump clean, etc. The problem is to reduce the slag pouring time twice, shorten the total slag pouring time, and enhance the slag pouring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

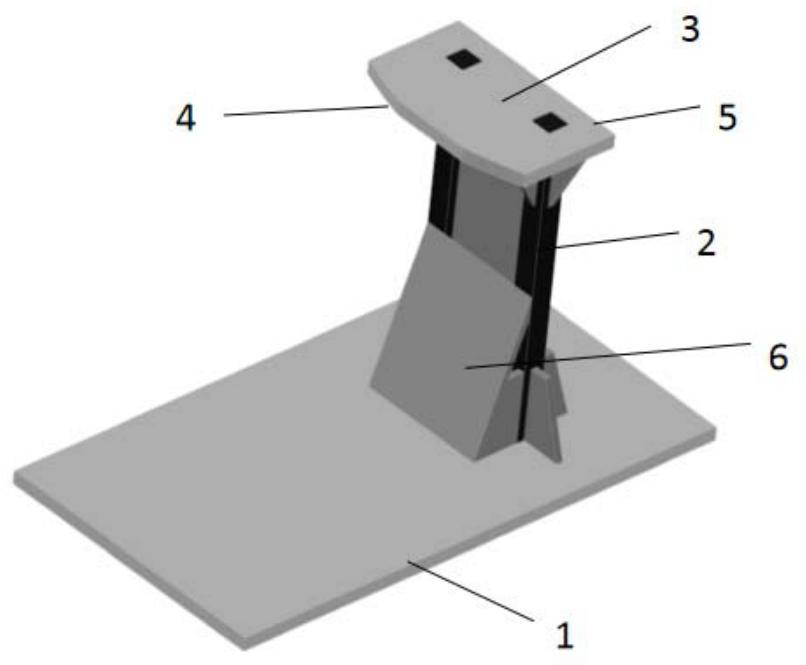

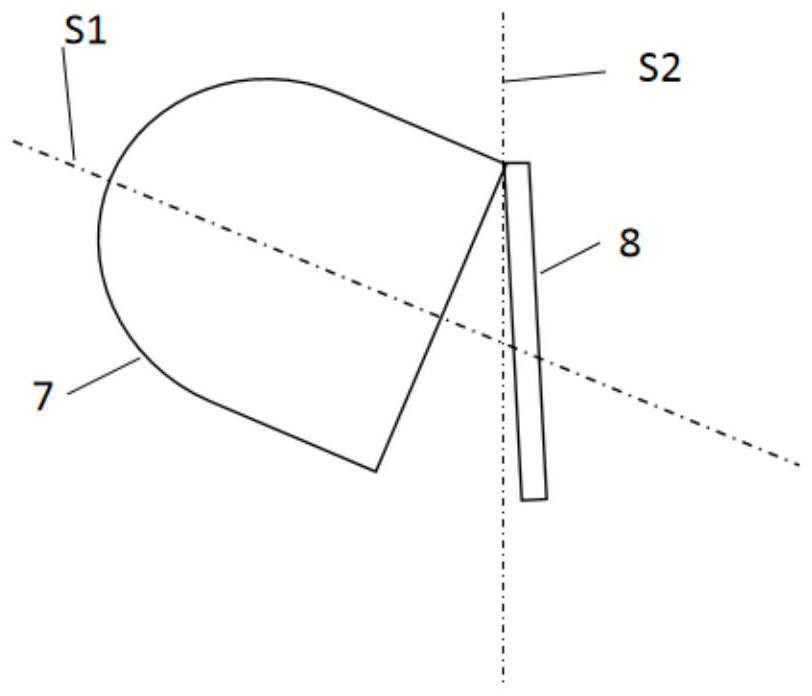

[0042] A method for quickly improving the cleanliness of a steel ladle with a cover, the time for hoisting the steel ladle 7 to the slag dumping position after casting is controlled within 5 minutes, hoisting the steel ladle 7 to the slag dumping position and starting a slag dumping, and the steel ladle 7 for dumping the steel slag The angle between the center line S1 of the ladle and the vertical line S2 on the ground is controlled at 119°, and the ladle 7 is backed up for the first time, and the angle between the center line S1 of the ladle and the vertical line S2 on the ground is 91°, hoisting to the hot repair platform seat for seat packing, the time from the start of one slag dumping to hoisting to the hot repair platform seat for seat packing is 2.5min, and the amount of slag dumping at one time accounts for 96wt% of the total slag dumping. The included angle between ladle center line S1 and ground vertical line S2 is 97°.

[0043] Command the crane again to hoist the l...

Embodiment 2

[0046] A method for quickly improving the cleanliness of a steel ladle with a cover, the time for hoisting the steel ladle 7 to the slag dumping position after casting is controlled within 6 minutes, hoisting the steel ladle 7 to the slag dumping position to start a slag dumping, and the steel ladle 7 for dumping the steel slag 7 The angle between the center line S1 of the ladle and the vertical line S2 on the ground is controlled at 120°, and the steel ladle 7 is aligned for the first time, and the angle between the center line S1 of the ladle and the vertical line S2 on the ground is 92°, hoisting to the hot repair platform seat for seat wrapping, the time from the start of one slag dumping to hoisting to the hot repair platform seat for seat lapping is 2 minutes, and the amount of slag dumping at one time accounts for 97wt% of the total slag dumping amount. The angle between the center line S1 and the vertical line S2 on the ground is 96°.

[0047] Command the crown crane a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com