A kind of automatic welding processing device and welding method thereof

A processing device and automatic welding technology, which is applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems of single welding method, affecting welding quality, and reducing work efficiency, so as to achieve simple and convenient operation, improve welding efficiency, and improve welding efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

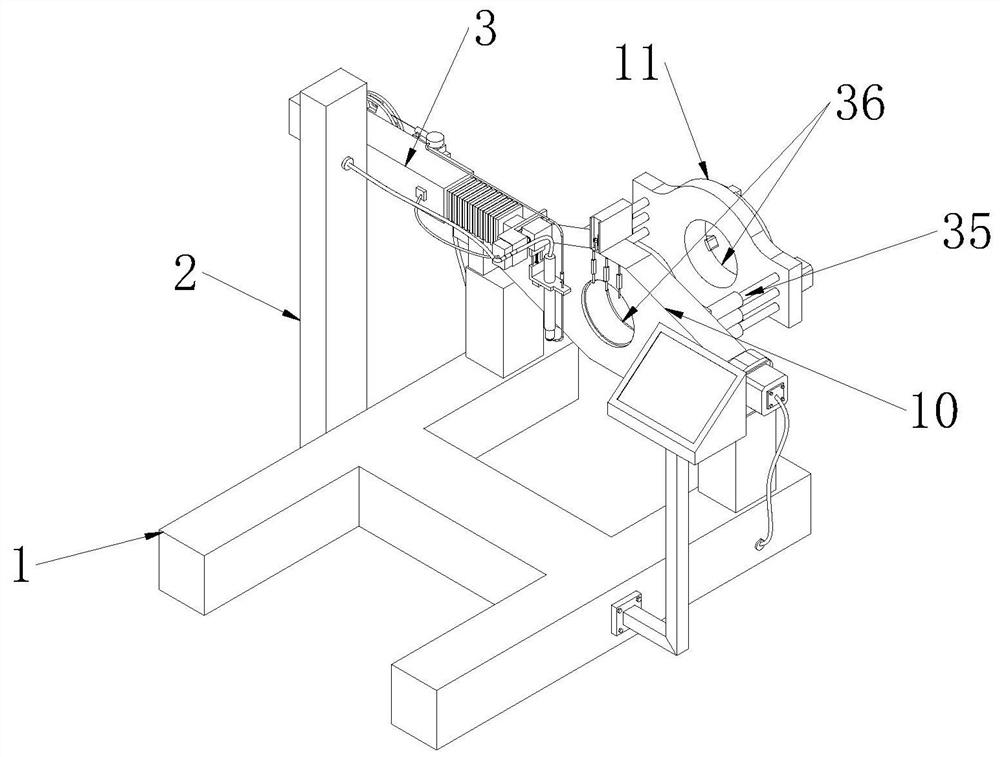

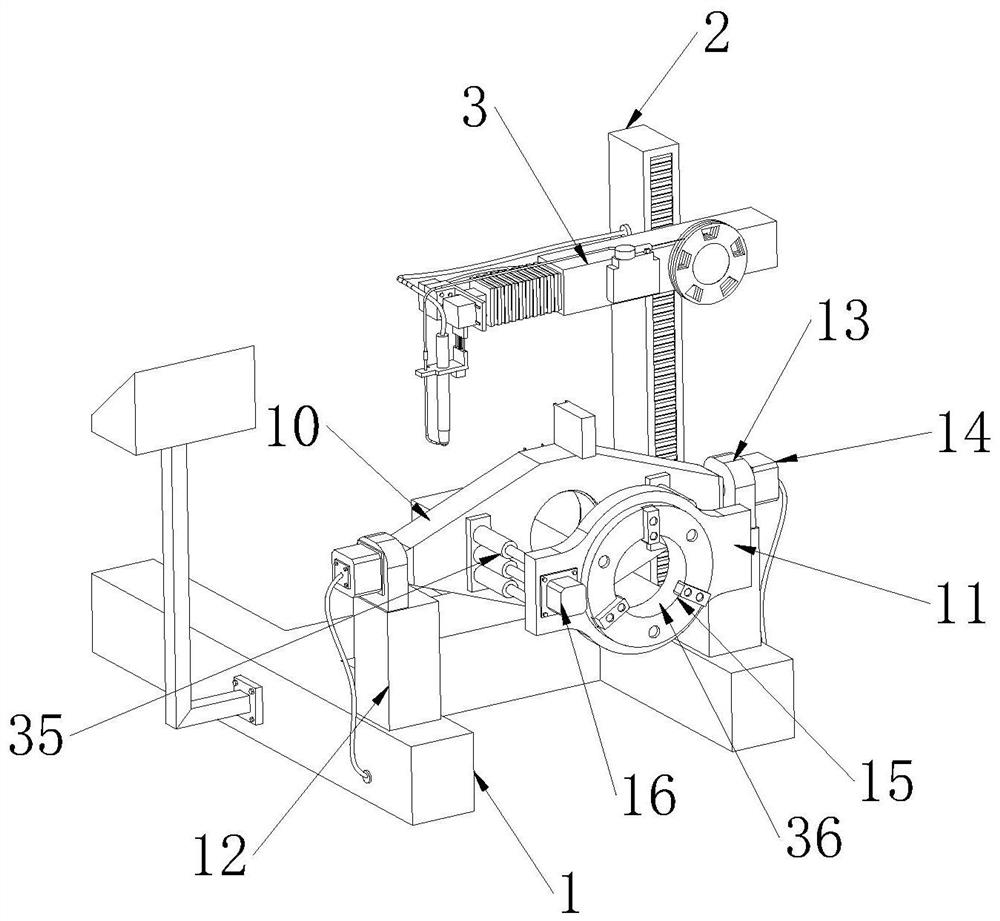

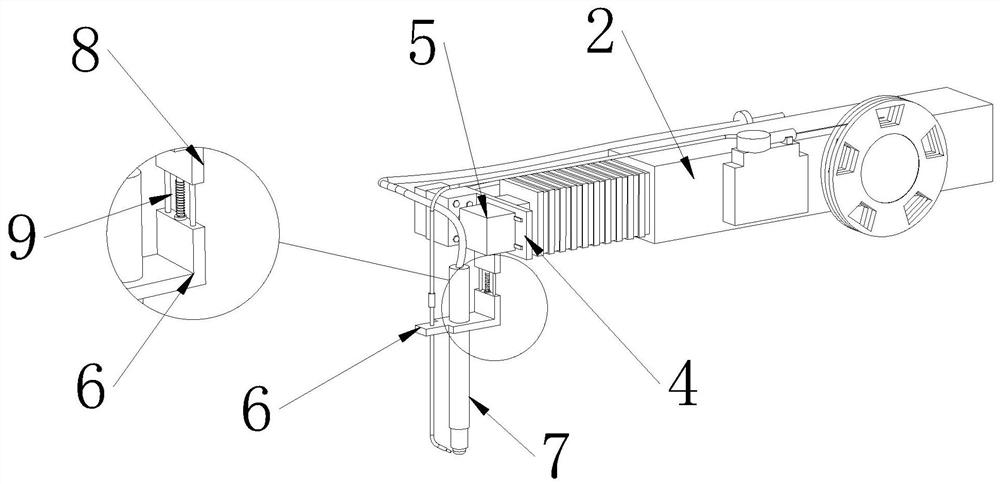

[0037] Example: such as Figure 1-2 As shown, an automatic welding processing device includes a base 1, and:

[0038] The welding mechanism includes a welding head and a mechanical arm with at least three axes, wherein the mechanical arm connects the base 1 and the welding head, and is used to support the welding head and adjust the spatial state of the welding head;

[0039] The fixing mechanism includes a first receiving plate 10 and a second receiving plate 11 arranged in parallel, wherein the first receiving plate 10 is connected to the base 1 in rotation, and a first driving member is installed at the rotating connection, and the first driving member works , adjust the angle of the first receiving plate 10, the second receiving plate 11 is connected with the first receiving plate 10 through the electric telescopic rod 35, expand and contract with the electric telescopic rod 35, adjust the distance between the second receiving plate 11 and the first receiving plate 10, On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com