Burr removing device for decorative plate processing

A technology for decorative plates and removal devices, which is used in metal processing equipment, grinding/polishing safety devices, machine tools suitable for grinding workpiece edges, etc. problem, to achieve the effect of accurate and reliable adjustment, avoiding horizontal slip adjustment, and convenient and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

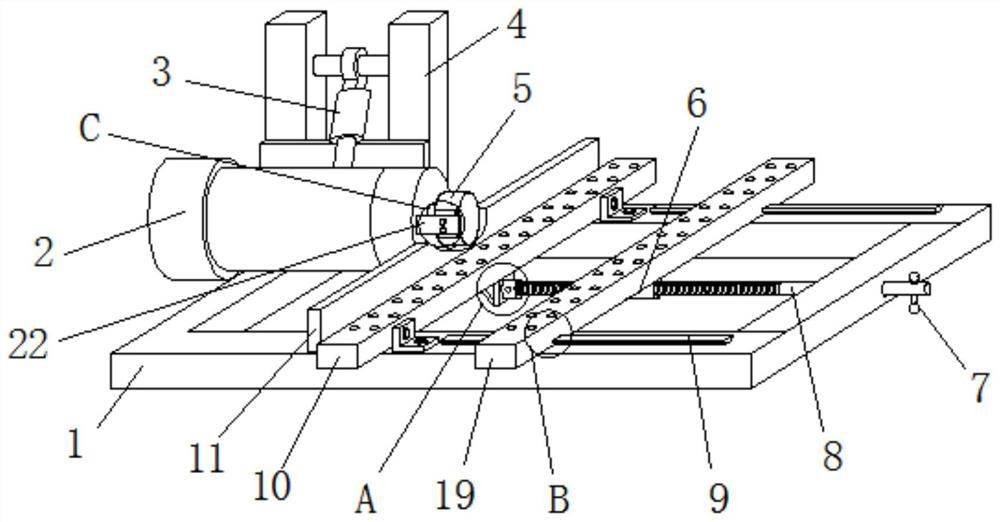

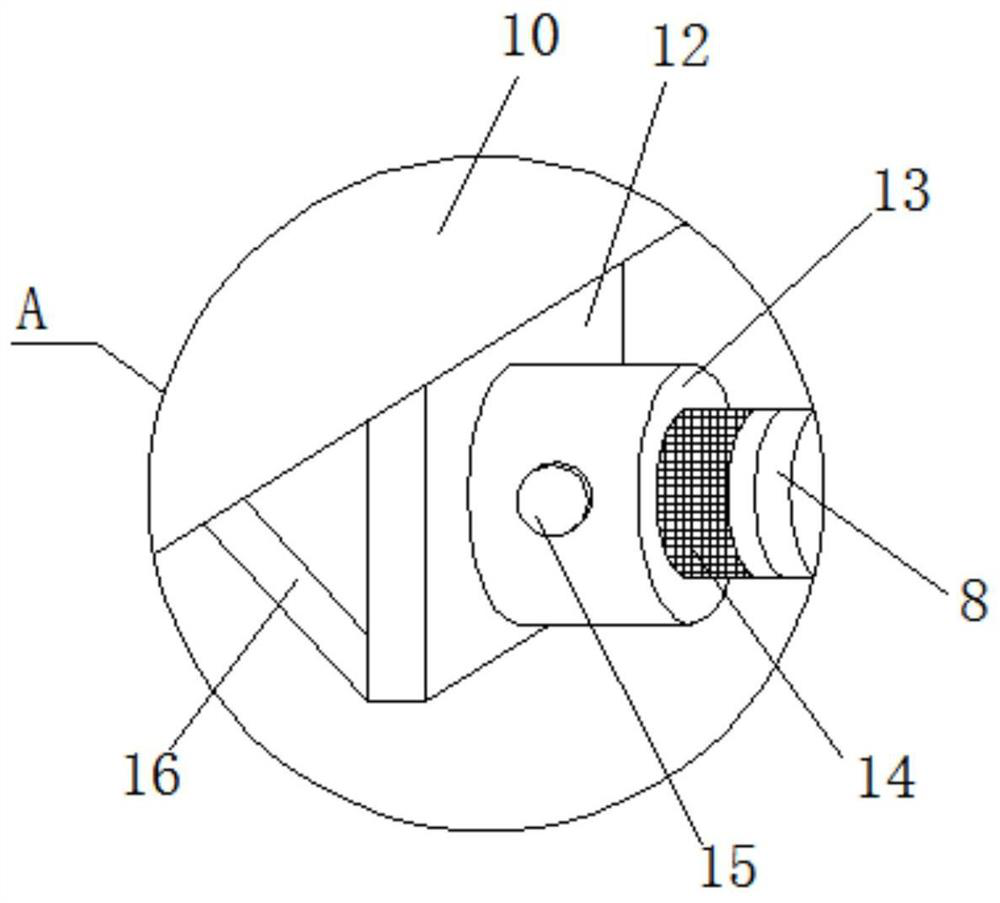

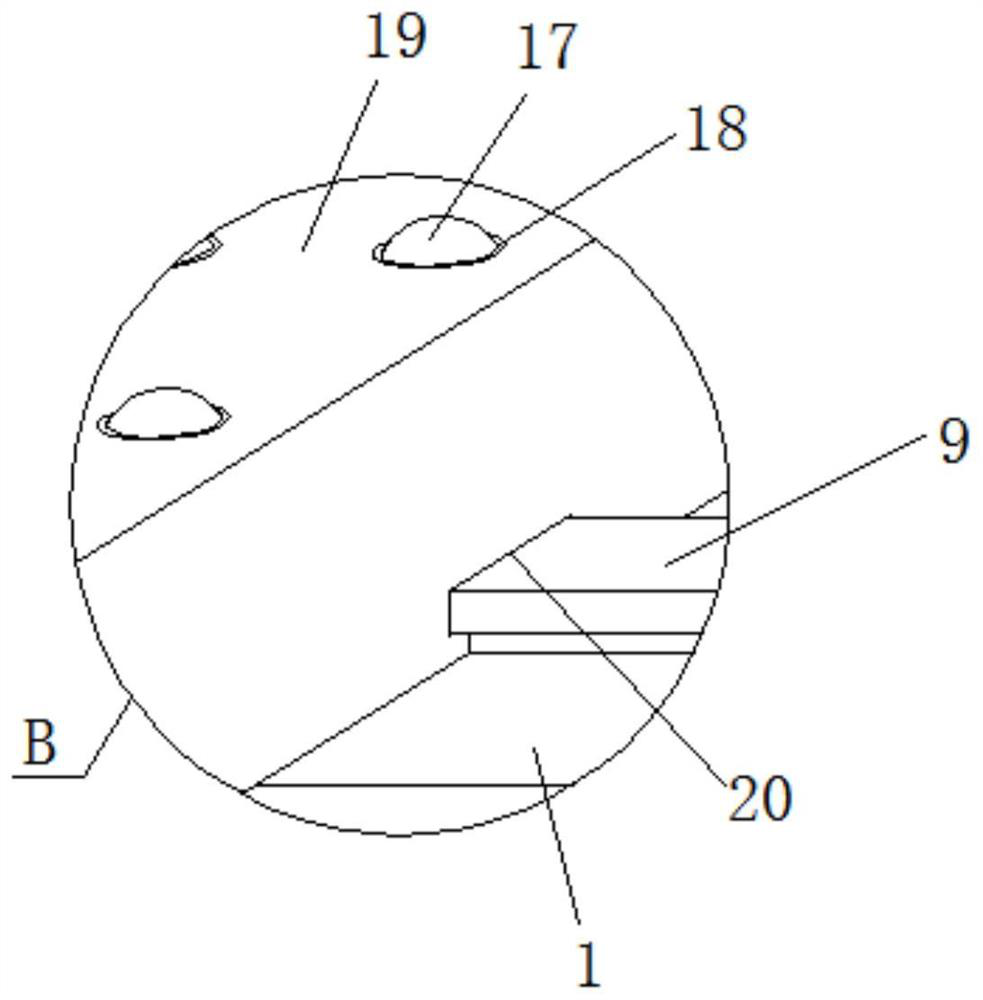

[0028] see Figure 1 to Figure 5 , the present invention provides a technical solution: a device for removing burrs for processing decorative panels, comprising a chassis 1, a bracket 4 is fixed on one side of the surface of the chassis 1, a servo motor 2 is arranged at the front end of the bracket 4, and the servo motor 2 and A hydraulic connecting rod 3 is connected between the supports 4, a grinding wheel 5 is fixed on the output end of the servo motor 2, and a fixing frame 10 is arranged on the bottom of the grinding wheel 5, and the fixing frame 10 is fixed on the surface of the chassis 1, and the fixing frame 10 One side is fixed with baffle plate 11, and the other side of fixed frame 10 is provided with movable frame 19, and the bottom end of movable frame 19 is fixed with spiral cylinder 6, and the inside of spiral cylinder 6 runs through threaded rod 8, and threaded rod 8 and spiral The cylinders 6 are connected by threads, one end of the threaded rod 8 runs through t...

Embodiment 2

[0032] see Figure 1 to Figure 5, the present invention provides a technical solution: a device for removing burrs for processing decorative panels, comprising a chassis 1, a bracket 4 is fixed on one side of the surface of the chassis 1, a servo motor 2 is arranged at the front end of the bracket 4, and the servo motor 2 and A hydraulic connecting rod 3 is connected between the supports 4, a grinding wheel 5 is fixed on the output end of the servo motor 2, and a fixing frame 10 is arranged on the bottom of the grinding wheel 5, and the fixing frame 10 is fixed on the surface of the chassis 1, and the fixing frame 10 One side is fixed with baffle plate 11, and the other side of fixed frame 10 is provided with movable frame 19, and the bottom end of movable frame 19 is fixed with spiral cylinder 6, and the inside of spiral cylinder 6 runs through threaded rod 8, and threaded rod 8 and spiral The cylinders 6 are connected by threads, one end of the threaded rod 8 runs through th...

Embodiment 3

[0037] see Figure 1 to Figure 7 , the present invention provides a technical solution: a device for removing burrs for processing decorative panels, comprising a chassis 1, a bracket 4 is fixed on one side of the surface of the chassis 1, a servo motor 2 is arranged at the front end of the bracket 4, and the servo motor 2 and A hydraulic connecting rod 3 is connected between the supports 4, a grinding wheel 5 is fixed on the output end of the servo motor 2, and a fixing frame 10 is arranged on the bottom of the grinding wheel 5, and the fixing frame 10 is fixed on the surface of the chassis 1, and the fixing frame 10 One side is fixed with baffle plate 11, and the other side of fixed frame 10 is provided with movable frame 19, and the bottom end of movable frame 19 is fixed with spiral cylinder 6, and the inside of spiral cylinder 6 runs through threaded rod 8, and threaded rod 8 and spiral The cylinders 6 are connected by threads, one end of the threaded rod 8 runs through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com