A vertical injection molding machine with automatic demoulding

An automatic demoulding and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of manual demoulding, low degree of automation, and many unsafe factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

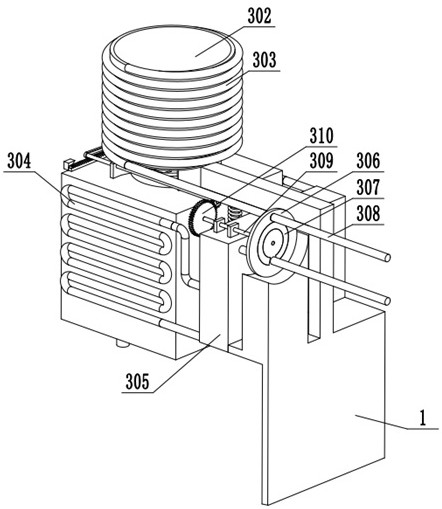

[0022] Example: such as figure 1 A vertical injection molding machine with automatic demoulding shown includes a base 1, a collection box 2, an injection molding device 3, an opening and closing device 4, and a discharge device 5. The base 1 and the collection box 2 are fixed on the ground.

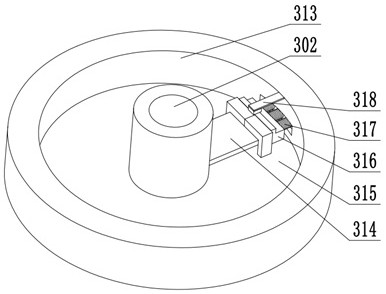

[0023] Such as figure 1 , figure 2 , image 3 The shown protective shell 301 is fixedly installed on the base 1, the feeding cylinder 302 and the base 1 are fixedly installed, the heating tube 303 is wound on the outside of the feeding cylinder 302, the switching disc 306 and the protective shell 301 are rotatably installed, and the transmission line 308 has two , and the protective shell 301 are fixedly installed, the contact piece 307 and the switch plate 306 are fixedly installed, the heating pipe 303 is fixedly installed through the wire and the protective shell 301, the cooling pipe 304 is fixedly installed on both sides of the cooling machine 305, the cooling pipe 304 is a hose, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com