Steel pipe hoisting device for building construction

A hoisting device and building construction technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of low steel pipe hoisting efficiency, frequent worker operations, and heavy labor, so as to reduce manual auxiliary installation, reduce manual operation, reduce artificial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

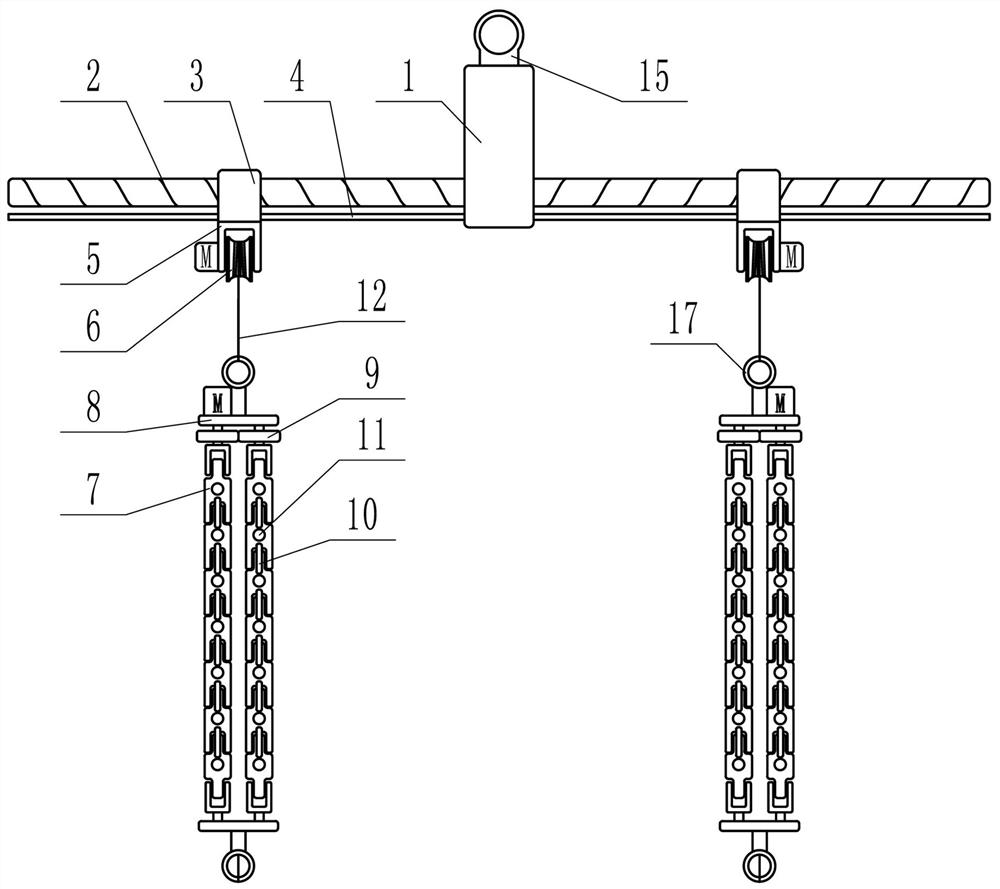

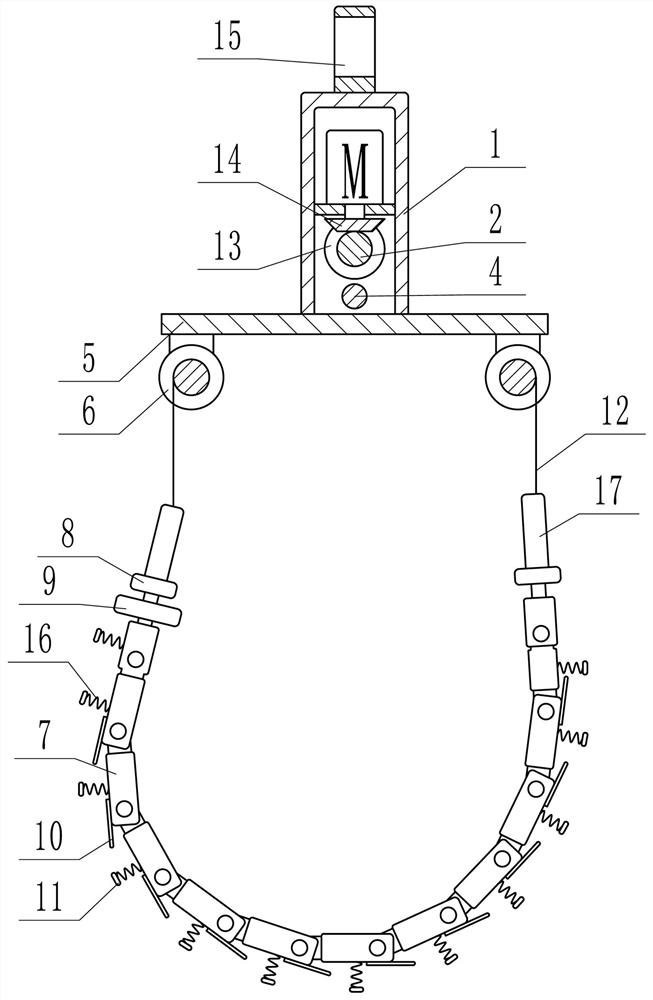

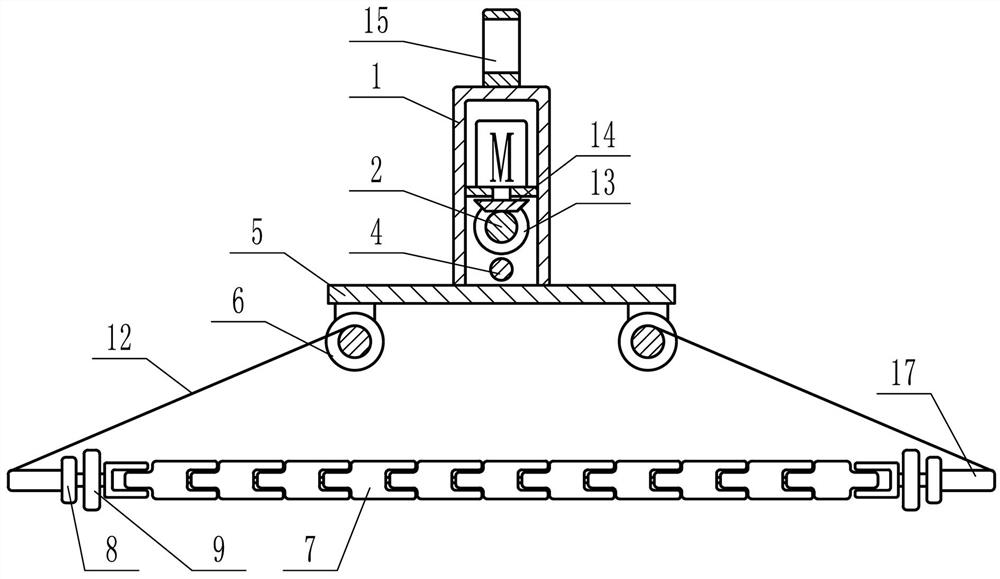

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Depend on Figure 1 to Figure 5 It can be seen that the present invention includes a support frame 1, and a threaded rod 2 is installed horizontally through and rotated on the support frame 1. The screw threads on the left and right sides of the threaded rod 2 are in opposite directions, and the left and right sides of the threaded rod 2 are each screwed with a nut. 3. A guide rod 4 that runs through two nuts 3 and slides with the nuts 3 is fixed under the threaded rod 2. A support plate 5 is fixed at the lower end of each nut 3, and a support plate 5 is fixed at the front and rear ends of the support plate 5. Reels 6 that can be driven independently, two reels 6 on the same support plate 5 form a group, two parallel chains 7 are arranged under each group of reels 6, and a support is provided at each end of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com